INSTALLATION AND OPERATING INSTRUCTIONS FOR

KELCO D40 DISPLACEMENT LEVEL SWITCH

The D40 top entry level switch operates by Archimedes

principle. When an object is immersed in a liquid its weight

is reduced by an amount equal to the weight of the liquid it

displaces. In the D40 level switch a magnetically actuated

switch detects the weight reduction that occurs when liquid

submerges a solid Polypropylene displacer suspended from

a cord below the switch. Since it is the change of weight

sensed by the displacer as it is submerged that actuates the

switch, the specifi c gravity of the liquid will directly effect the

operation of the switch. The D40 level switch will only

operate in liquids that have a specifi c gravity that is 0.95 or

greater (water). They will not operate if used in liquids with

an S.G. of less than 0.95.

The D40 level switch is an extremely versatile device. It can

be used to detect a liquid level in wells, tanks, pits, sumps,

bores and bund areas. The inert materials of construction

mean the switch can be used in water, sea water, mild acids

and in many common chemical solutions. The D40 is highly

tolerant of liquids containing solids, slurries or pulp. It will

also work reliably in froth or foam and in applications where

there is fl oating scum or debris of various kinds.

The electrical enclosure on the D40 level switch is sealed

and separated from the switch’s actuating arm by a solid

metal wall. The switch is actuated magnetically through the

solid wall. This means the electrical housing is totally sealed

and weatherproof provided the lid is fully tightened and the

cable gland is properly utilised. The Polypropylene

suspension cord and the displacer are the only components

in contact with the process liquid. Polypropylene is a very

inert material and is well known for its resistance to many

commonly encountered chemicals.

The D40 is ideal for warm liquid applications provided the

electrical head is mounted well above the liquid and is

protected from hot vapour. The wetted components, the

cord and displacer are highly tolerant of liquids at elevated

temperatures.

INTRODUCTION

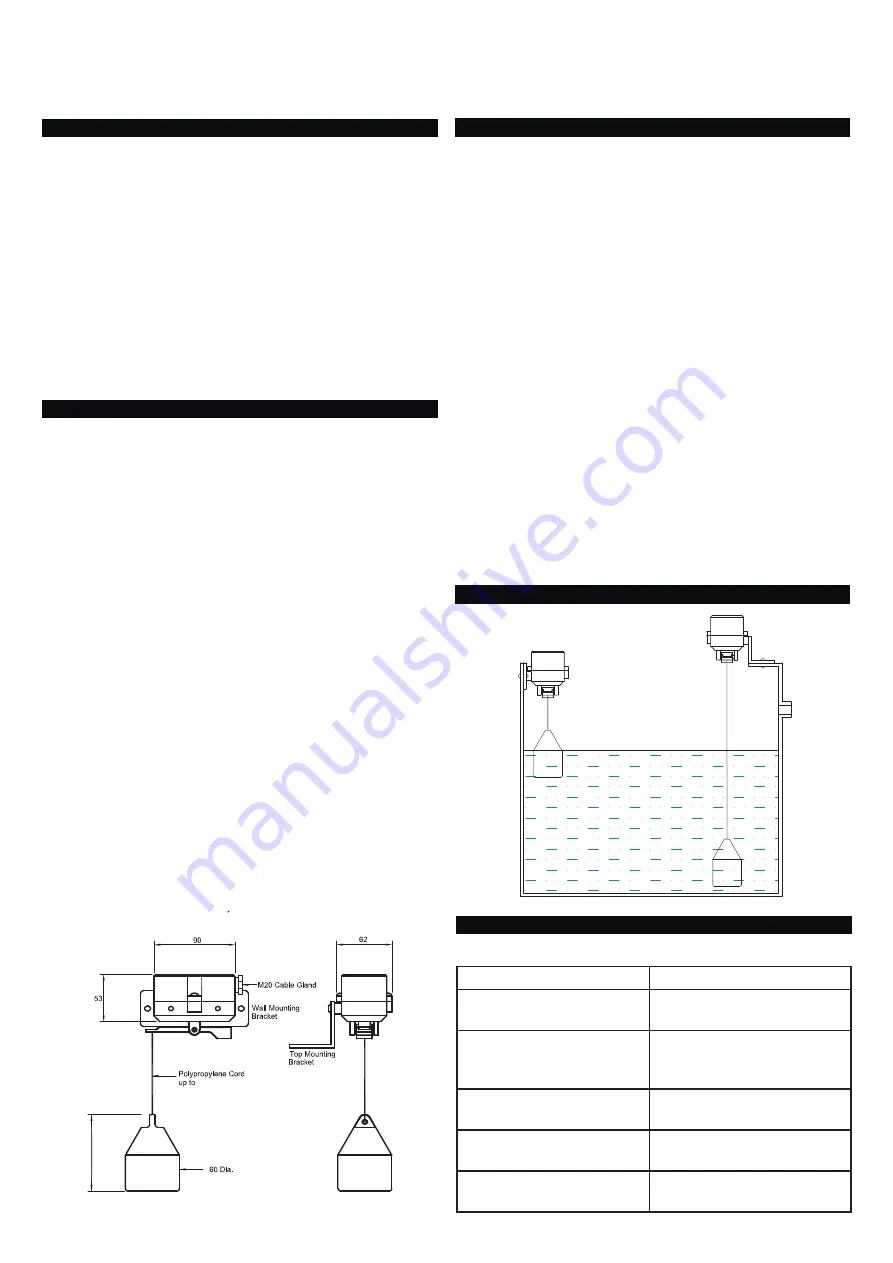

INSTALLATION

OPERATING ENVIRONMENT

The D40 level switch is supplied with a fl at mounting plate

for installing the switch against the walls of pits or tanks. In

addition to the fl at plate, an angle bracket is also supplied.

The angle bracket can be used to mount the switch on any

fl at horizontal surface such as tank lids or horizontal bracing.

M5 threaded mounting holes are provided in the sides of the

switch body so the switch can be oriented with its cable entry

pointing to the right or left.

Whichever mounting bracket is used, ensure that once

installed, the top face of the D40’s lid is perfectly horizontal.

This ensures the cord and displacer hang vertically beneath

the switch and apply force to the switch arm directly

downwards.

Thread the supplied cord through the hole at the end of the

switch actuating arm and tie a double knot in it so the cord

can’t pull back through the hole. Thread the free end of the

cord through the hole in the top of the displacer and tie it off

securely. D40 level switch is supplied with 3 metres of cord.

Cords up to 20 metres in length can be used with the D40

switch and are available from Kelco or your supplier if

required.

TYPICAL INSTALLATIONS

Fixed switching differential 40mm +/- 5mm

Maximum distance

between D40 & displacer.

20 metres (3m of cord is

supplied with the switch)

Minimum distance from

displacer to the fl oor of a

tank or sump.

20mm

Minimum inside diameter

of pipe housing or shroud.

70mm

Maximum liquid

temperature.

90°C

Specifi c gravity of process

liquid.

0.95 or greater

LIMITATIONS

20m

long

115