SAFETY AND ADJUSTMENTS

SAFETY

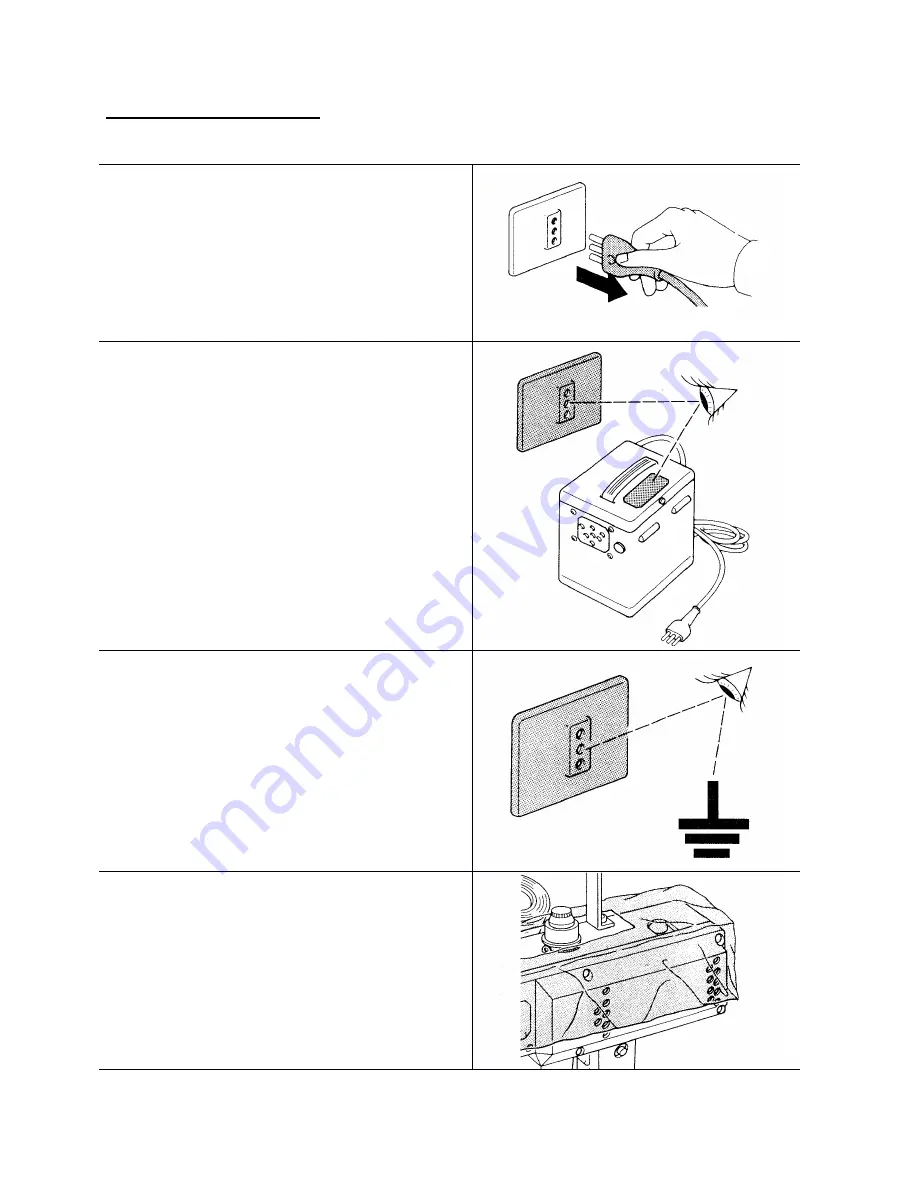

The machine has to be disconnected from the

power supply by pulling out the main plug before:

1. Threading needle and looper. 2.replacing any

parts such as needle presser foot, throat plate,

looper, spreader, feed dog, needle guard, folder,

fabric guide etc. 3. Leaving the workplace and

when the work place is unattended. 4. Doing

maintenance work.

Check if the voltage of the sewing motor

corresponds with the voltage of the wall socket.

The rated voltage is marked in the label of

transformer or machine.

Wall sockets for machines with ground wire must

be porperly grounded.

Do not block up the thermal hole of the motor.