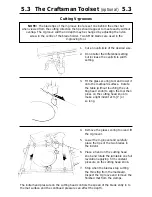

Blades

The Oval 6 has been designed to use standard craft knife blades:-

Material

Operation

use blade...

Regular matboard

Cutting all except very small ovals/circles

SM02

Regular matboard

Cutting very small ovals/circles

SM03

Thick matboard and foamcore

Cutting all sizes of oval/circle

SM03

All materials

Cutting V-grooves

SM02

Replacement blades and glass cutting wheels are available through your Keencut distributor or from Keencut direct.

Cleaning and Lubrication

●

Clean the Oval 6 frequently with a damp or dry cloth and keep it covered when not in use.

Dirt can spoil your work

●

Do not use solvents, they can harm the paint finish, remove silicone lubrication and effect plastic components.

●

Lubrication. Use lubricant spray, apply it with a pad or cloth. Wipe off any excess liquid with a clean cloth.

●

Do not use oil, grease or all-purpose penetrating oils and sprays. Silicone spray may be used on the operating

disc under the table if ever required.

Fault Finding

Fault

Causes and Suggestions

Start/Finish mark

- Hand Pressure applied to the cutting head before the turntable

had rotated to align the cutter

- Pressure applied to the cutting head too suddenly

- Blade depth not correct

Cutting needing more than two

- Change Blade

revolutions on regular matboard

- Apply more pressure

Poor finish on the bevel

- Blunt or broken blade

- Insufficient hand pressure on the cutting head

Excessive blade wear or tip

- Glass cutting surface scored

breakages

- Blade depth incorrect

A double cut around part of

- Blade depth incorrect

the bevel

- Inconsistent pressure on the blade

- Not enough pressure on the cutting head during cutting

Extreme lazy ovals (not vertical)

- Turntable rotating in the wrong direction

- Slide block wrongly set and adjusted (see ‘Cutting small ovals’)

Ovals or circles not centred

- Scales not accurately set or adjusted on the clamp bars or

in matboard

turntable edge.

V-groove not meeting up after

- Blade tips need resetting to meet exactly when viewed from the direction

one revolution

of cut. Please note that the blades are set one behind the other when

viewed from below.

The

Dexter No. 3

blade is also

suitable.

SM02

Glass

cutting wheel

SM03

6.1

Looking After Your Oval 6

6.1

Maintenance and Blades