Q.1.23 November 2014

Page 17

Mounting the Controller

Once the wiring has been run to the controller location, the controller

can be connected. When installing the KE2 Controlled Environment,

the (4) screws supplied in the kit may be preinstalled in the mounting

surface. The controller has keyholes in each mounting tab to allow

the controller to be installed over the screws. The mounting pattern

can be seen in Figure 10.

User Interface

The KE2 Controlled Environment’s onboard user interface uses a

familiar 6-button arrangement to simplify navigation through the

controller’s menus. The menu has been grouped by category to pro-

vide an easy to program structure. By grouping the menu by each

functional area, the user is not required to scroll though unrelated

setpoints to access the desired functionality.

The left and right arrows move between the categories. When

pressed while in a menu, the left and right arrows will move to the

main screen or the adjacent menu.

The up and down arrows move the user through the available op-

tions for each group. All users are allowed access to the variable

alarms. All other information is password protected to prevent unau-

thorized access to the controller’s functionality.

Use ENTER button to save an input option when it has been changed.

Button must be held for 3 seconds to prevent accidental changes.

Changes may be discarded by waiting, to allow the controller to time-

out and return to default screen, or pressing BACK button.

The BACK button is used to return to the previous screen. Pressing

the BACK button twice at any time will return the user to the default

view. See Table 2 (following page).

Controller Setup

Upon initially applying power to the controller, the controller will ini-

tialize, then automatically enter the Introduction Mode. The Intro

Mode consists of as little as 4

setpoints that must be configured for

KE2 Controlled Environment to begin controlling the system.

Table 1 shows the Intro Mode. The first setpoint the user is asked to

enter is the desired ROOM TEMP. This is followed by the TARGET

HUMIDITY, then DEFROST TYPE. The controller is designed to work

with electric, hot gas, and off time defrosts. The last setpoint is the

VALVE TYPE. The controller is defaulted to be used with a KE2 EEV,

but may be used with a mechanical valve or a customer defined valve.

These are the only setpoints required to begin controlling the system,

when applied on a single evaporator with a mechanical valve, See

Table 1.

Adjusting Controller Parameters

The controller has the ability to access an abundance of informa-

tion from the 4-digit alphanumeric display. However, the controller

requires a password, adding a degree of protection from unwanted

modifications. The controller will prompt the user for a password

PASSWORD when the user attempts to access setpoints they do not

have permission to change.

Table 2 shows the menu structure of the controller. The default dis-

play of the controller always displays the actual room temperature.

Pressing the up and down arrows moves the display through the

VARIABLES menu. See Table 2 By default, the controller only allows

access to the room temperature. The VARIABLES menu consists of

the current sensor readings and the relays’ state. The User Password

(1111) only provides access to the ROOM TEMP setpoint.

For the protection of the system, access to the SETPOINT and

MANUAL control requires an Installer Password (2222). Pressing

the right or left arrow will move from the Variables menu to the next

menu, shown in Table 2, a complete list of parameters are shown in

Table 3.

Pressing the BACK key at any time will return the user to next level

up the menu. A second press will either return to the Main Menu or

to the room temperature reading.

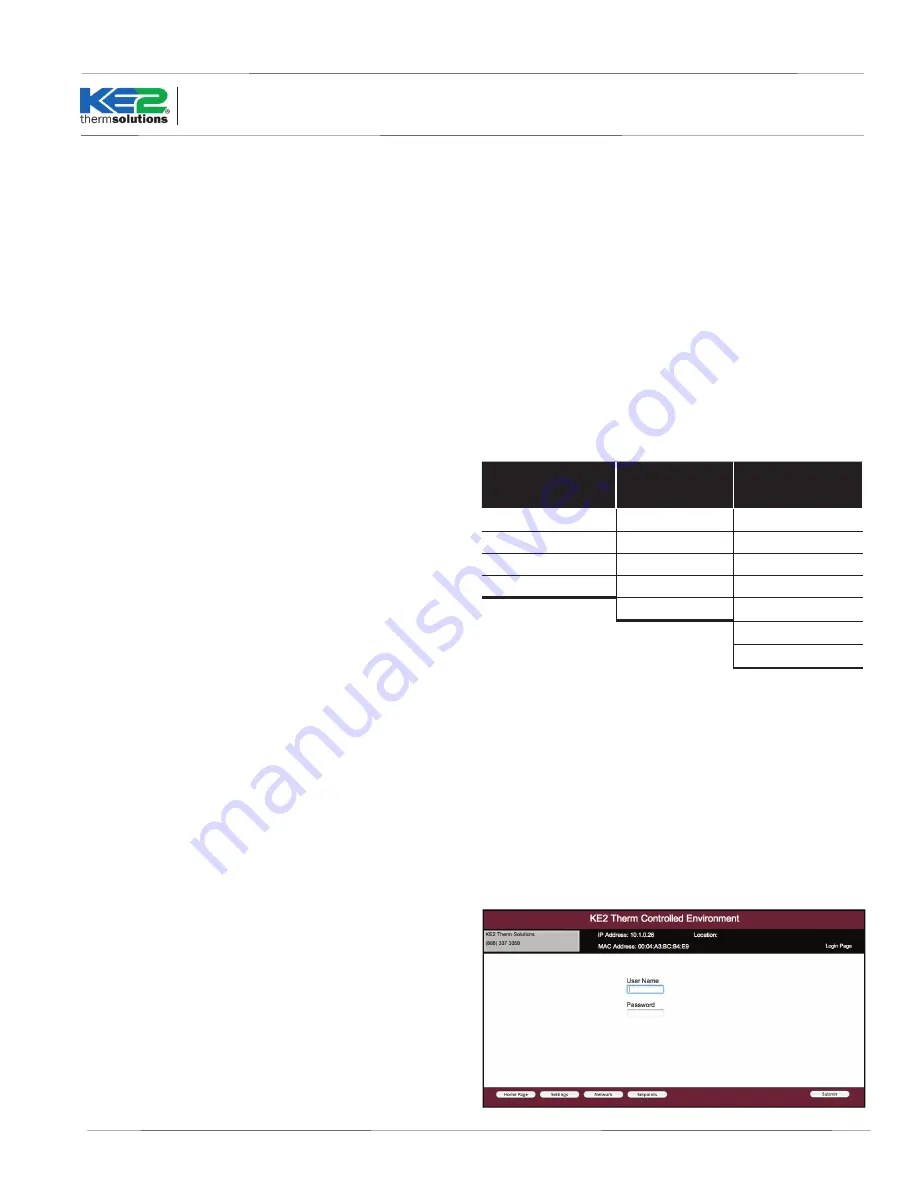

Table 1 - Introduction Menu

Mechanical Valve TEV

4 steps

KE2 HSV

(default)

5 steps

Custom EEV

7 steps

Room Temp

Room Temp

Room Temp

Target Humidity

Target Humidity

Target Humidity

Defrost Type

Defrost Type

Defrost Type

Valve Type

Valve Type

Valve Type

Refrigerant

Refrigerant

Step Rate

Max Steps

If using a standard/predefined EEV, the user will also be prompted

to specify the REFRIGERANT. Once these have been set, the KE2

Controlled Environment will begin controlling EEV and the system.

Table 3

Web Login

When accesssing the controller using the webpage, the Username

and Password are required.

The defaults are set as: User: ke2admin

Password: ke2admin

IMPORTANT: The Password should be changed from the default

for security purposes.

KE2

Controlled

Environment

Quick Start Guide

Wine Cellar 2

ke2admin

ke2admin

© Copyright 2014 KE2 Therm Solutions, Inc., Washington, Missouri 63090