24

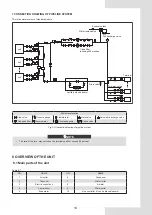

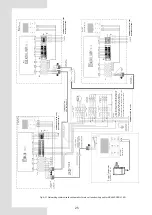

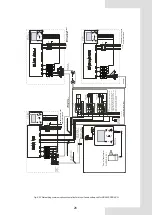

8.4.14 Wiring instances

If multiple units are connected in parallel, the user needs to set uint address on the DIP switches.

The DIP switch address is ENC4. With 0-F being valid, 0 indicates the main unit and 1-F indicate auxiliary units.

Fig. 8-20 Networking communication schematic of main unit and auxiliary unit for KEM-30 DRS4.1 KH

L1

L2

L3

N

¡

¥

CN

2

CN6

0

CN74

CN61

CN60

CN7

4

CN61

;<

($

%

CN60

CN74

CN6

1

;<

($

%

;7

X

Y

;<(

;<(

CN8

3

;7

CN3

0

;7

;7

CN2

CN8

3

CN3

0

;7

;7

CN2

CN83

CN30

/

/

/

L1

L 2 L3

L1

L 2 L3

L1

L 2 L3

L1

L 2 L3

ENC4

ENC4

ENC4

$

%

;

<

($

%

;

<

($

%

;<(

;7

;7

1

1

CN8

7

MONIT

OR

WIRECONTROLER

MONIT

OR

WIRECONTROLER

WH

BR

BK

YE

RD

WH

BR

BK

YE

RD

WH

BR

BK

YE

RD

WH

BR

BK

YE

RD

HEA

T1 HEA

T2 COM COMP-ST

ATE PUMP

HEA

T1 HEA

T2 COM COMP-ST

ATE PUMP

POWER 380-415V 3N~50Hz

R

VV

-300/500 5X10mm

2

POWER 380-415V 3N~50Hz

R

VV

-300/500 5X10mm

2

POWER

POWER

COMMUNICA

TION

WITH NEXT

MODULE

COMMUNICA

TION

WITH NEXT

MODULE

COMMUNICA

TION

WITH NEXT

MODULE

POWER 380-415V 3N~50Hz

R

VV

-300/500 5X10mm

2

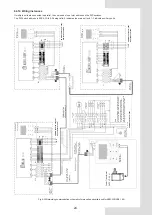

The length of wire

should be shorter

than 500m

The Wiring

Terminal X

、

Y

and E on the back of Wire Controller are correspondin of the T

erminal

X

、

Y and E of

Wiring Board in Main Module

MAIN CONTROL

WIRECONTROLER

Power T

ransformer

OUTPUT

: 8.5 V~

POWER

MAIN CONTROL

WIRECONTROLER

WH

BR

BK

YE

RD

WH

BR

BK

YE

RD

HEA

T1 HEA

T2 COM COMP-ST

ATE PUMP

COMMUNICA

TION

WITH WIRE

COMTROLLER

Over-current

relay

Over-current

relay

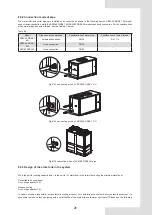

Notes The wiring diagram of auxiliary heaters is just for reference, please follow the instructions of corresponding auxiliary heater products. Please choose such accessory as power wire, switch of auxiliary heater according to the actual parameter of products and national

The metal plate of contactor installation box should be grounded

Auxilia

ry heater

for pipeline

Over-current

relay

Contactor

Contactor

Contactor

PUMP

POWER 380-415V 3N~50Hz

Auxilia

ry heater

for water tank

Содержание KEM-90

Страница 52: ......