39

Periodic inspection

This instrument requires some regular checking, which is very important to keep

your instrument up and running.

Katanax knows that a broken instrument in a laboratory setting causes sample

back-up and unnecessary costs. That is why this manual comprises not only a

chapter (see page 43),

which guides the user in a step-by-step fashion through operations that

sometimes need to be performed on-site.

If unsure, do not hesitate to get in touch with a Katanax technician (see page 55,

Note that no modifications of the instrument, except those explicitly described and

permitted in this manual, are allowed. Any undue modification automatically

cancels the warranty and could endanger the user's life.

Warning

IMPORTANT

: Some of the procedures described in the following pages imply a

risk of death by electrocution; those procedures shall be executed only by

trained personnel.

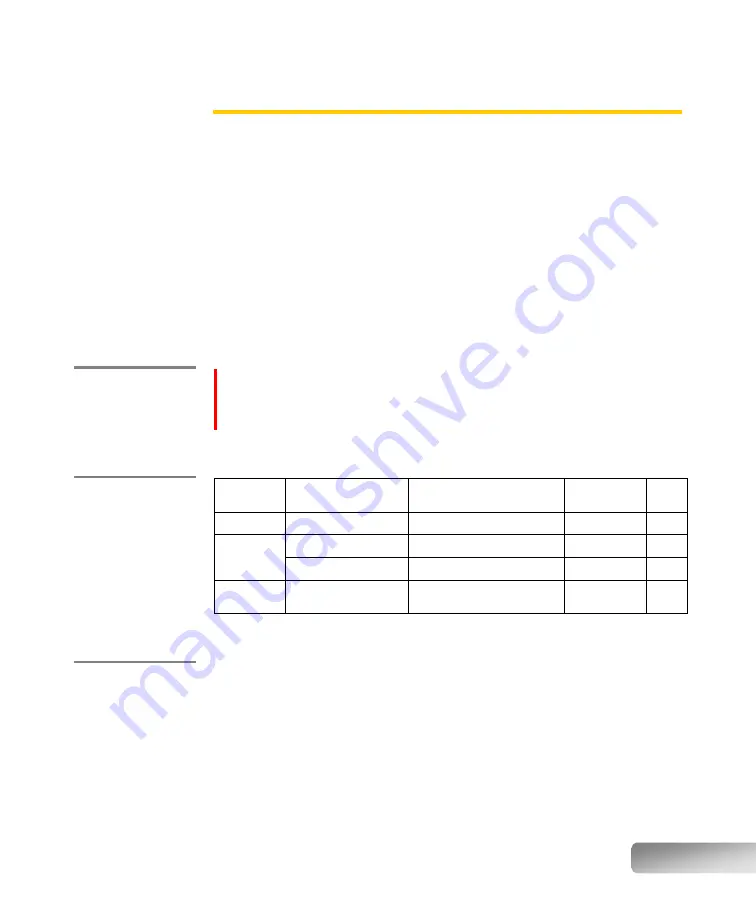

Inspection

schedule table

Frequency

Checkpoint

Description

Action

(if problem

found)

Page

Every

fusion

Check for flux deposits

Cleaning

1 month

or

100 cycles

Visual integrity of

heating elements

Check elements integrity,

section and pitch regularity

Replace

Check for correct tightening

and oxidation

Re-tighten or

replace

3 months

or

300 cycles

Check junction

Replace

Flux spillages

This procedure describes an easy, yet crucial, step to be completed before each

fusion cycle. Flux spillages (residues), if left un-cleaned, can lead to a rapid

deterioration of key components of the fluxer.

1.

This visual inspection should be done every fusion cycle.

1.1

Look for vitrified, darker or colored spots on the ceramics or metal parts

that make up the mold and the crucible heaters.

1.2

In the case that a spillage has occurred on one or more parts of the

heaters, clean or replace immediately. Ceramic and metallic parts of the

Содержание K1 PRIME

Страница 1: ...Automatic fluxer 1...

Страница 2: ......