-

7

Raise the sweeper from the front and

drive it on to a smooth, even surface

covered with a visible layer of dust or

chalk.

Lock parking brake.

Let the sweeping roller rotate for ap-

prox. 15-30 seconds.

Raise the sweeper at the front and drive

it towards the side.

The sweeping track should have an even

rectangular shape which is between 30 and

40 mm wide.

Adjust sweeping track:

Adjust the left and right adjustment le-

vers and engage into the same boring.

–

Engage adjustment lever into the lower

boring (+): Sweeping track becomes

bigger

–

Engage the adjustment lever into the

upper boring (-): Sweeping track be-

comes smaller

Check sweeping mirror.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear is evident.

Note

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

Unscrew 3 screws from the underside

of the side brush.

Remove the wiper blade.

Clip new side brushes on to driver and

screw on.

Adjustment is necessary if a visible deterio-

ration in sweeping performance caused by

side-brush is evident.

Release the wing nut.

Adjust the adjustment screw.

Tighten the wing nut.

–

Adjustment is necessary if the bulk

waste flap cannot be raised wide

enough.

–

The Bowden cable needs to be re-

leased a little if the sweeper results be-

come poorer, for e.g. due to the wearing

of the front lip.

Loosen counter-nut.

Adjust the adjustment screw.

Tighten the counter-nut.

Note

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

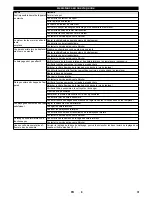

Front sealing strip

Loosen the fastening screws of the

sealing strip.

Adjust or replace sealing strip.

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 0-10 mm.

Adjust sealing strip.

Tighten the fastening of the sealing

strip.

Rear sealing strip

Remove the waste container.

Loosen the fastening screws of the

sealing strip.

Adjust or replace sealing strip.

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 0-10 mm.

Tighten the fastening of the sealing

strip.

Side sealing strips

Loosen the fastening screws of the

sealing strip.

Adjust or replace sealing strip.

To set the floor clearance, insert a

sheet with a thickness of max. 2 mm un-

der the sealing strip.

Adjust sealing strip.

Tighten the fastening of the sealing

strip.

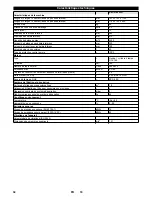

Danger

Empty waste container before replacing

dust filter. Wear a dust mask when working

around the dust filter. Observe safety regu-

lations on the handling of fine particulate

material.

Lock parking brake.

Shake off dust filter.

Open the locking screw of the dust filter

cover in an anticlockwise direction.

Lift the dust filter cover.

Replace dust filter Make sure the dust

filter is inserted correctly (see figure).

Screw in the locking screw all the way.

몇

Warning

If the locking screw is not tightened all the

way, there may be damages.

Note

Make sure when installing the new filter

that the fins are not damaged.

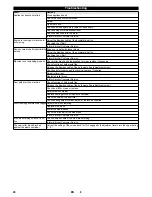

Check and adjust roller brush sweeping

track

Setting range

(-) 1...10 (+)

Minimum sweeping track

1

Maximum sweeping track

10

New roller brush

1...3

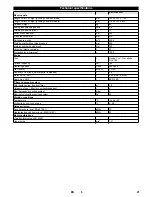

Replacing side brush

R

L

R

L

Adjust side-brush lowering

Adjust the raising of the bulk waste flap

Adjusting and replacing sealing strips

Replacing dust filter

Accessories

Hard side-brushes

6.905-625.0

For removing stubborn dirt in the external

area; resistant to moisture.

Roller-brush, soft

6.906-886.0

With natural bristles especially for fine dust

sweeping on smooth indoor floors. Not re-

sistant to wetness; not for abrasive surfac-

es.

Roller-brush, hard

6.906-885.0

For removing stubborn dirt in the external

area; resistant to moisture.

Roller brush, antistatic 6.906-950.0

19

EN

Содержание KM 75/40 W G

Страница 22: ...283...

Страница 23: ...http www kaercher com dealersearch...