- 16 -

User may purchase consumables from manufacturer of the boiler.

Use only manufacturer‘s spare parts

8.

Fuel types and properties

Combustion heat of absolutely dry wood does not depend on the kind of

wood and equals 4510 kcal/kg. So in order to compare different kinds of

wood we need to assume their relative weight. 1m

3

weighs:

- oak wood

- 500 kg;

- birch wood

- 450 kg;

- fir wood

- 330 kg;

- asp wood

- 330 kg.

The higher wood humidity – the less calorie value. Decrease in calorie

value of humid wood in comparison to 20% humidity wood:

- 30 % humidity

- 10

÷

15 %;

- 50 % humidity

- 35

÷

40 %.

Fresh cut tree has about 35

÷

60 % water. Wood cut in the beginning of

winter or hard wood has least water.

Peat and wood calorie value is similar.

1 kg of coal gives 2

÷

3 times more heat than 1 kg of wood.

Combustion of 1 kg of wood requires 4

÷

5 m3 of air, coal – around 10

m3.

The more ash is left – the worse fuel is.

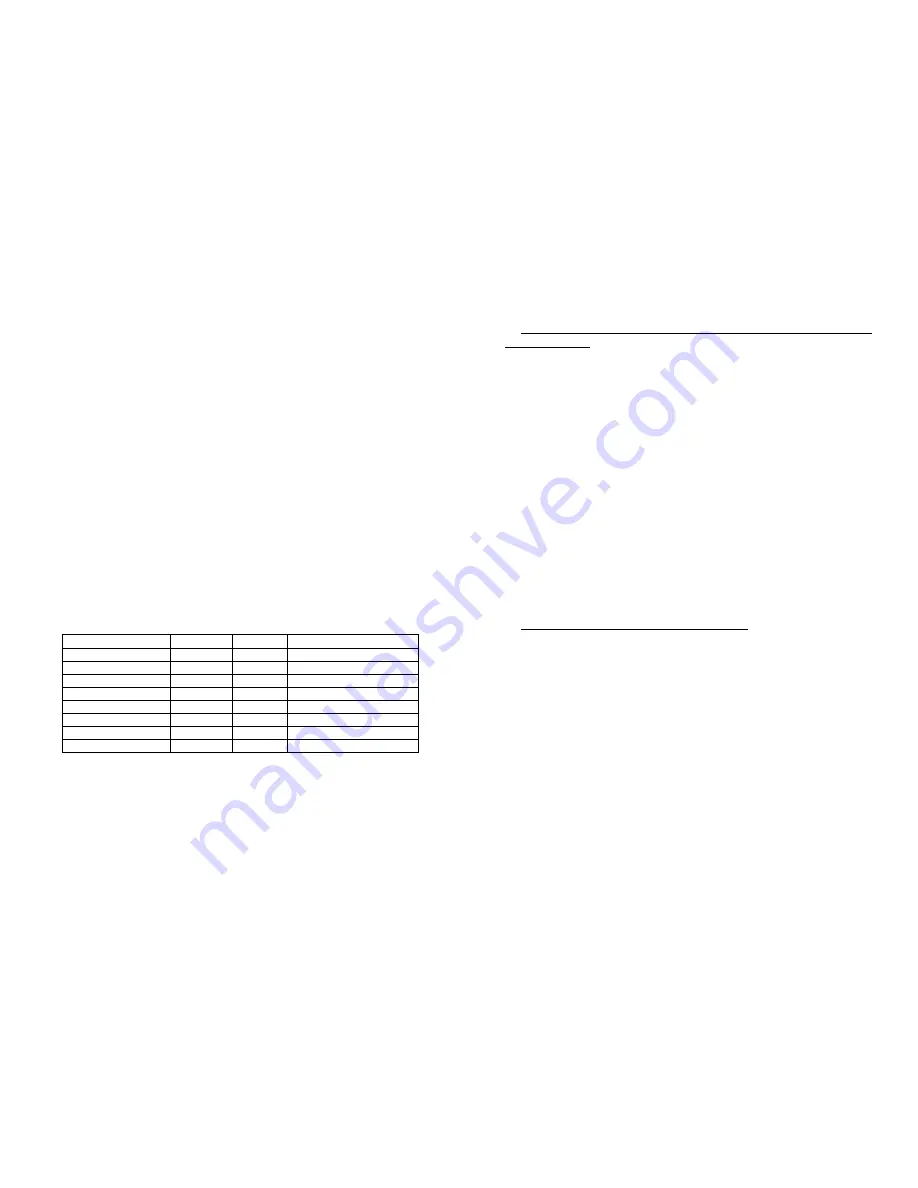

Energy radiation from combusting 1 dm3 of wood of 20 % humidity:

Wood type

Kcal

Kwh

Comparison to oak %

Oak, maple

2520

2,93

100 %

Ash 2460

2,86

98

%

Birch 2270

2,64

90

%

Alder

1900

2,21

75 %

Pine

1850

2,15

73 %

Asp 1810

2,10

72

%

Polar 1680

1,95

67

%

Fir 1610

1,87

64

%

Average coal caloric value 6500 kcal/kg (7,56 kWh/kg).

9.

Operating burner.

Boiler uses PellX pellet burner. Operating burner is described in pellet

burner PellX user‘s manual.

- 5 -

KALVIS – 6MPP 2009.05.18

2.

Design description

Boiler design is constantly improved. There may be minor deviations

from this manual.

Boiler frame is welded from steel sheets and has water cavities where

water is heated (see 1 fig.). Internal walls are 6 mm thick, external – 4mm.

Bopiler exterior is covered with insulation shields (p.16). In the front of the

boiler there is a draught adjuster (p.1), that controls air damper (p.6);

thermomanometer (p.2), doors (p.4), with servicing doors (p.5) behind them

and an ash tray (p.7). Fuel loading chamber is closed with a cover (p.18),

with installed secondary air valve (p.19).

In the chamber there is a catalyst plate (p.17) and fire grate (p.8). For

servicing of internal boiler surfaces, under the top insulation shield (p.16)

there is a cover (p.15). Catalyst plate (p.17) should be removed when firing

coal.

On the sides of the boiler there are covers (p.9) used to remove the ash.

On the back side of the boiler there are drain water (p.10), return water

(p.11) and hot water (p.14) piepes with G2-B thread; smoke outlet with

smoke damper (p.20).

Burner (p.24) is moutned on boiler‘s burner door (p.23). Burner has a

separate manual. Fuel pipe (p.25) supplies granulated fuel from the tank

(p.26. Burner and fuel pipe are connected by a hose (p.27). Burner hole

cover (p.28).is mounted when firing wood.

It is prohibited

to alter the design of the boiler.

3.

Transportation and storage.

Transport boilers only in vertical position by all types of covered

transport. Transporting by not covered transport is possible only when the

weather is dry. Use additional protection means to protect boilers against

fall downing and scratching. Striking, turning over or throwing boilers

during loading, unloading or transportation time is strictly prohibited.

The boilers are to be stored in the dry rooms, where there is no

vapour of chemicaly active materials.

4.

Boiler mounting

Boiler shouild be mounted in premises, complying with the requirements

of RSN-159-95 ir RPST-01-97 and according to the rules of installation of

solid fuel boilers in premises ST 8860273.02:1998.

Boiler should be mounted vertically, or with forward inclination not

exceeding 1

o

.

Exhaust cover should be moutned above the boiler.

Содержание 6 MPP

Страница 9: ...12 9 KALVIS 6MPP 2009 05 18...

Страница 10: ...10 11 KALVIS 6MPP 2009 05 18...