KAIRAK

Page 9

- 9 -

IM-ES-REV 5-09-06.doc5-09-06

OPERATION

A thermometer is provided on all refrigerator and freezer cabinets.

Allow cabinet to reach normal operating temperature before loading (approximately 1 hour).

The refrigerated storage cabinet is designed to maintain temperatures between 33

°

F and 40

°

F,

or –2

°

F to 2

°

F for a freezer storage cabinet. If the base is overloaded with warm food products,

a certain amount of time is required to remove heat from items before operating temperatures

can be maintained. The system is designed for storage of refrigerated or frozen product.

Frequently opening the drawers will increase the temperature in the cabinet and will require a

certain amount of time to recover.

SHUTDOWN FOR EXTENDED PERIODS

If the units are not to be used for an extended period of time, disconnect the electrical power

supply and the drawers to the storage cabinet. As soon as the cabinet has warmed to room

temperature, wipe out the base interior.

MAINTENANCE PROCEDURES

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY

PARTS ON THE UNIT.

STORAGE CABINET

Use warm, soapy water to clean storage cabinet and doors. NEVER use cleaners containing

grit, abrasive materials, bleach or harsh chemicals. Rinse thoroughly and dry with a clean soft

cloth. Always rub in the same direction as the grain pattern on the stainless steel.

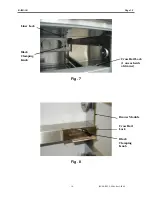

Remove the drawers from the drawer frame module. The drawer frame module can be removed

by loosening the black clamping knob on the Cross Rail Locks and Liner Locks. Pull the Cross

Rail Locks toward the center of the drawer frame module and allow the Liner Locks to drop

away from the top of the liner. The entire frame assembly is now free to slide out of cabinet.

(See Figs. 7 & 8).