10 Maintenance

10.1 Safety

The following instructions must be followed for safe machine maintenance.

Warning instructions are always given before a potentially dangerous action.

Basic safety instructions

1. Follow the instructions in chapter 3 'Safety and Responsibility'.

2. Maintenance work may only be carried out by authorized personnel!

3. Before switching on, make sure that:

■ no one is working on the machine,

■ all access doors and panels are closed and secure.

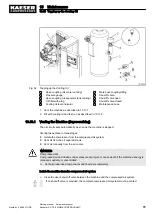

Working on electrically conducting components.

1. Work on electrically conducting components may only be carried out by authorized electricians.

2. Switch off and lock out the supply disconnecting device and check that no voltage is present.

3. Check that there is no voltage on floating relay contacts.

Working on pressure systems

1. Close shut-off valves or otherwise isolate the machine from the air main to ensure that no com‐

pressed air can flow back into the machine.

2. Vent all pressurized components and chambers completely.

3. Check all machine hose connectors with a handheld pressure gauge to ensure that all read zero.

4. Do not open or dismantle such valves.

Working on the drive

1. Switch off and lock out the supply disconnecting device and check that no voltage is present.

2. Do not open the enclosure while the machine is switched on.

Further information Specification of authorized personnel is found in chapter 3.4.2.

Specification of dangers and their avoidance is found in chapter 3.5.

10.2 Maintenance Schedule

10.2.1 Logging maintenance work

The maintenance intervals given are those recommended for average operating conditions.

➤ Maintenance tasks should be carried out more frequently where operating conditions are

unfavorable (e.g. dusty atmosphere) or when the equipment is heavily utilized.

➤ Adjust the maintenance intervals with regard to operating conditions.

10 Maintenance

10.1 Safety

Number: 9_6945 01USE

Service manual Screw compressor

Aircenter SX 3/7.5 SIGMA CONTROL BASIC

53