2-8

2.2.7 Capstan motor, load gear, control plate

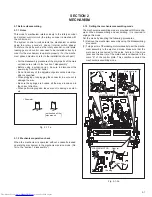

2.2.7.1 Removal

(1) Detach the belt.

(2) Check that the FFC connector on the drum is disconnected.

(3) Release the catch (a) to remove the FFC wire.

(4) Remove the screws (a) to detach the capstan motor.

(5) Remove the screws (b) to detach the fixing plate.

(6) Release the catch (b) to detach the load gear.

(7) Turn the load gear (S/T) in the loading direction to detach it.

(8) Remove the control plate.

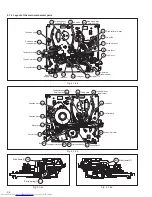

2.2.6.2 Installation (phase adjustment)

(1) Attach the loading motor assembly to the main deck.

(2) Secure the screw (a).

(3) Solder the wire to section (a).

(4) Arrange the wire along with the position guide (b).

(5) Attach the capstan brake assembly to the main deck.

(6) Place the main deck on the guide hole (a) of the control plate.

(7) Place the main deck on the guide hole (b) of the drive lever.

(8) Place the main deck no guide hole (c) of the control cam to

install the control cam.

(9) Move the capstan brake in the direction shown by the arrow

(a) to attach the press lever to the shaft (a). Make sure that

the boss of the press lever fits in the control cam, and that

the shaft (b) of the pinch roller arm assembly connects with

the hole of the press lever.

(10) Attach slit washer (a) to shaft (a).

Fig. 2-2-6b

Fig. 2-2-7a

Screw (a)

Shaft (a)

Shaft (b)

PRESS LEVER

Slit washer (a)

Arrow (a)

Guide hole (c)

Loading motor assembly

CONTROL CAM

Guide hole (b)

Shaft (a)

CONTROL

PLATE

DRIVE

LEVER

Capstan brake assembly

Guide hole (a)

Position

guide (b)

Wire (black)

Wire (red)

Section (a)

Catch (a)

Catch (b)

Screws (b)

CONTROL

PLATE

LOAD GEAR

FFC

Load gear (T) assembly

Load gear (S) assembly

LOAD GEAR

FIXING PLATE

Capstan motor assembly

BELT

Screws (a)

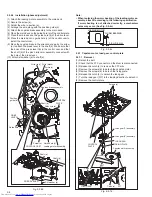

Note:

•

When replacing the worm bearing of the loading motor as-

sembly, attach it according to the following specification.

If worm bearing is not attached correctly, a mechanism

noise may occur. (See Fig. 2-2-6c)

Fig. 2-2-6c

6.8

±

0.2 mm

WORM BEARING

LOADING MOTOR