(No.YF075)1-17

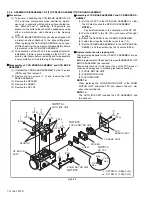

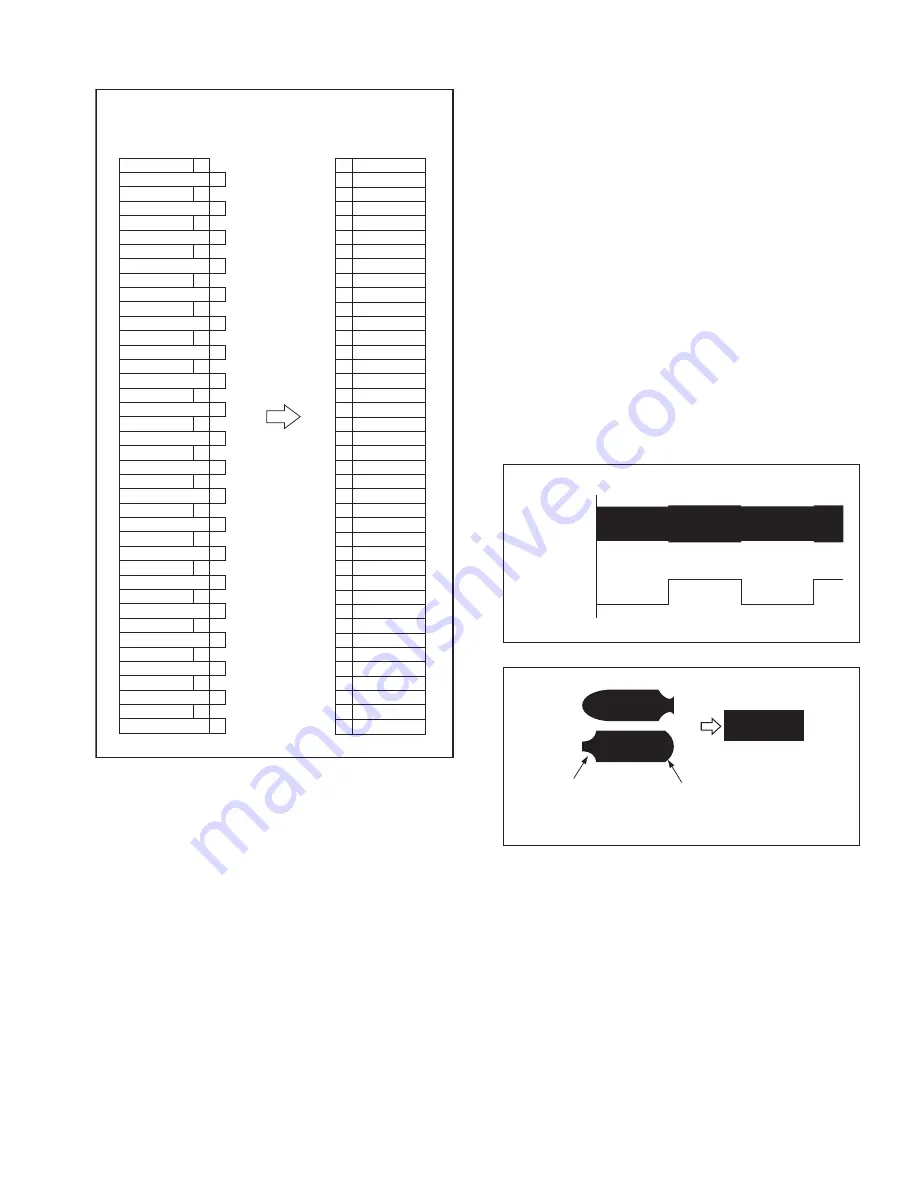

Jig connector diagrams

Fig.4-2-2

4.3

MECHANISM COMPATIBILITY ADJUSTMENT

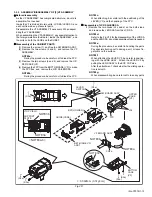

4.3.1 Tape pattern adjustment

NOTE:

Prior to the adjustment, remove the COVER (ADJ).

(1) Play back the compatibility adjustment tape.

(2) While triggering the HID, observe the waveform of

ENV_OUT.

(3) Set the manual tracking mode (ATF OFF).

(4) Confirm that the waveform is entirely parallel and straight,

and free from remarkable level-down, through the tracking

operation.

Make the confirmation as follows if necessary.

(5) If level-down is observed on the left hand side of the

waveform, straighten the level by turning the GUIDE

ROLLER (SUP).

If level-down is observed on the right hand side of the

waveform, straighten the

level by turning the GUIDE ROLLER (TU).

(6) After the adjustment, try the unloading motion once, and

confirm that the waveform is flat when the tape has been

played back again.

(7) Play back the self-recording.

(8) Confirm that the waveform is flat.

Fig.4-3-1

Fig.4-3-2

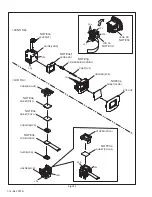

4.4

ELECTRICAL ADJUSTMENT

Electrical adjustment is performed by using a personal computer

and software for SERVICE SUPPORT SYSTEM. Read

README.TXT file to use the software properly.

As for the connection of cables, see "4.2 JIG CONNECTOR

CABLE CONNECTION".

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

EXMOD_1

SYS_TMS

SYS_TCK

SYS_TDI

SYS_TRSTL

SYS_TDO

SYS_RSTL

AL_3VSYS

IF_TX

JLIP_TX

JLIP_RX

TXD2

RXD2

NC

I_MTR

NC

NC

ENV_OUT

MAIN_VCO

ATFI

HID

DISCRI

FS_PLL

HST

MON_B

MON_R

MON_B

GND

GND

V_OUT

HRP

CVF_B

CVF_R

CVF_G

GND

NC

NC

DSC_DBG

KENTO

MVD

EXMOD_1

SYS_TCK

SYS_TRSTL

SYS_RSTL

IF_TX

JLIP_RX

RXD2

I_MTR

NC

MAIN_VCO

HID

FS_PLL

MON_B

MON_B

GND

HRP

CVF_R

GND

NC

KENTO

SYS_TMS

SYS_TDI

SYS_TDO

AL_3VSYS

JLIP_TX

TXD2

NC

NC

ENV_OUT

ATFI

DISCRI

HST

MON_R

GND

V_OUT

CVF_B

CVF_G

NC

DSC_DBG

MVD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

JIG CONNECTOR CABLE (YTU93106C)

MAIN CN113

JIG CONN. BOARD

(PIN NO.)

ENV_OUT

HID

Flatten the waveform.

Misalignment of guide roller

height on the take-up side

Misalignment of guide

roller height on the

supply side