(No.YD085)1-31

4.10.3 Linearity adjustment

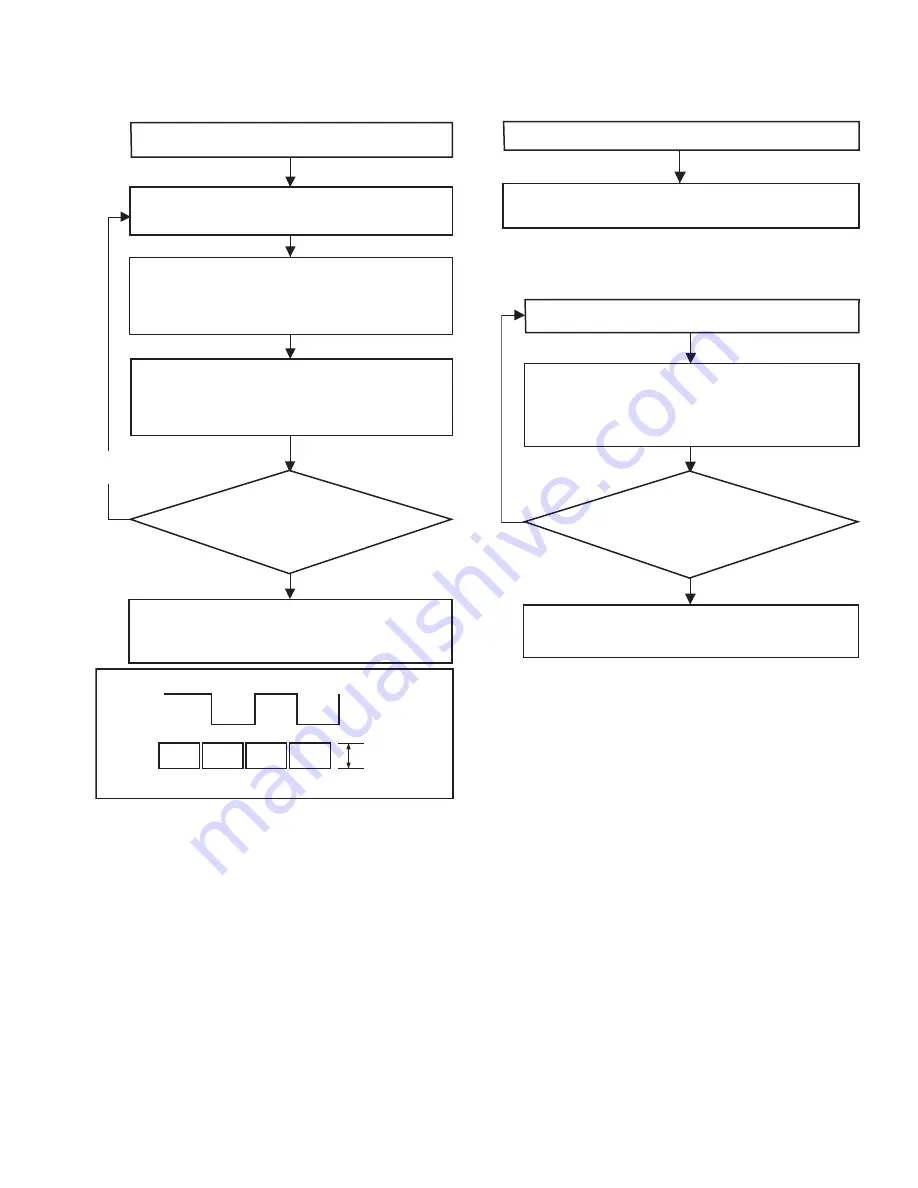

The following flowchart shows the linearity check/adjustment

procedure.

Fig.4-10-4

Note 3 :

• If ATF is turned off, the DV section performs tracking only of

the speed system. Therefore, as time passes, the servo will

be lost and the linearity adjustment will become difficult.

Note 4 :

• Since the speed servo function is active when ATF is off,

there will be no problem even if the DVC ATF function is off,

provided that it is for a few minutes.

4.10.4 PB switching point adjustment

The following flowchart shows the PB switching point adjustment

procedure.

4.10.5 Error rate adjustment

The following flowchart shows the error rate adjustment proce-

dure.

Note 5 :

• The "typical value" refers to the following:CH1 or CH2: < 498

; with Viterbi OFF. Inter-channel difference: < 10 times be-

tween CH1 and CH2.

Note 6 :

• It is desirable to use a brand-new tape or an unused section

of tape. This is to assure the adjustment reliability because

using a damaged tape increases the error rate.

4.10.6 Error rate measuring method

It is not necessary to use the error rate jig (YTU93083) or a fre-

quency counter. The Service Support System Software displays

the error rates of video CH1, CH2 and totals. When measuring

the error rate of a channel, be sure to total the values of the video

and the audio errors.

Play the alignment tape, then set “ATF” (Auto Tracking

Find) in “Deck Controller” of the SSS Software to ON.

(Note 3)

Connect an oscilloscope (CH: + Slope) and, while

triggering it with the HID signal, observe the ENV OUT

The linearity adjustment is complete if the PB ENV

waveform is ideally stable and varies ideally according to

the tracking variation. To close, play a prerecorded tape

and check the audio and video.

Is the PB ENV waveform ideally

stable and does it vary ideally

according to the tracking variation?

Yes

No

Ensure that the ENV OUT waveform is linear and parallel,

without a noticeable drop or variation in the overall level. If

the waveform linearity is poor or there is a noticeable drop

in level, adjust the guide roller by turning it with the roller

driver.

Set “ATF” (Auto Tracking Find) to OFF using “Deck

Controller” of the SSS Software (Note 4). Observe the ENV

OUT waveform to confirm that the overall waveform

balance and linearity levels vary in accordance with the

tracking variation as shown in Fig. 4-10-4.

Repeat above steps

as required.

PB ENV

waveform

Adjust variation

in the parallelism

HID waveform

CH1

CH2

The “PB Switching Point” in the Adjustment Utility of

the SSS software is adjusted automatically.

Load the alignment tape.

While playing the recorded signal, adjust “VCO Center

Frequency (ME SP)” or “VCO Center Frequency (ME LP)” in

“Deck Section” of the Adjustment Utility.

To adjust VCO Center Frequency (ME SP) : Set Viterbi OFF.

To adjust VCO Center Frequency (ME LP) : Set Viterbi ON.

Record for about 5 minutes. (Note 6)

The error rate adjustment is complete when the minimum

error rate which is no higher than the typical value is

obtained. (Note 5)

Is the obtained error rate minimum

(almost the typical value)?

Yes

No