No. 51944

AV28CH1EUS

AV28CH1EUB

8

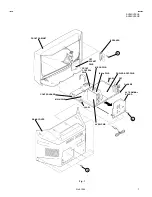

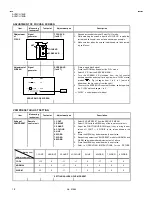

REMOVING THE CRT

∗

Replacement of the CRT should be performed by 2 or more

pers ons.

•

After removing the c over, chassis etc.,

1. Putting the CRT c hange table on soft cloth, the CRT change table

should also be c overed with s uch soft cloth (shown in Fig.3).

2. While keeping the s urfac e of CRT down, mount the TV s et on the

CRT change table balanced will as shown in Fig.4.

3. Remove 4 sc rews marked by arrows with a box type screw driver

as s hown in Fig.4.

•

Sinc e the cabinet will drop when screws have been removed, be

sure to support the cabinet with hands.

4. After 4 screws have been removed, put the cabinet slowly on

cloth (At this time, be carefully so as not to damage the front

surfac e of the c abinet) shown in Fig.5.

•

The CRT should be ass embled according to the opposite

sequence of its dismounting steps.

∗

The CRT change table should preferably be smaller that the CRT

surfac e, and its height be about 35c m.

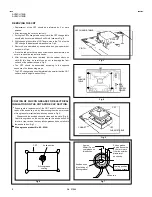

COATING OF SILICON GREASE FOR ELECTRICAL

INSULATION ON THE CRT ANODE CAP SECTION.

•

Subsequent to replac ement of the CRT and HV transformer or

repair of the anode cap, etc. by dis mounting them, be sure to coat

silicon grease for electrical insulation as shown in Fig.6.

Wipe around the anode button with clean and dry cloth. (Fig.6)

Coat silic on greas e on the section around the anode button. At

this time, take c are so that any silicon greas es dose not stic k to

the anode button. (Fig.7)

★

★

★

★

Silicon grease product No. KS - 650N

CRT CHANGE TABLE

CLOTH

APPROX.

35cm

CRT

CRT

CHANGE

TABLE

BOX

TYPE

SCREW

DRIVER

Fig. 3

Fig. 6

Fig. 7

Approx.

20mm (Do not

coat grease on

this s ection

Silic on greas e

should be coated

by 5mm or more

from the outs ide

diameter of

anode c ap.

Anode button

(No sticking of

silicon grease)

Coating position

of silicon grease

Anode cap

Anode button

CRT

Silic on greas e

coating

Fig. 5

CRT

CABINET

CRT

CHANGE TABLE

Fig. 4