MO-6900J Series

MO-6900G Series

The machine incorporates a mechanism and parts that

are optimum for the sewing of extra heavy-weight

materials, such as an extra high-lift type upper looper,

tractor foot and coarse type feed dog.

It demonstrates an excellent performance ability in the

sewing of various kinds of heavy-weight materials such

as jeans, raised fabric materials, mats and carpets.

■

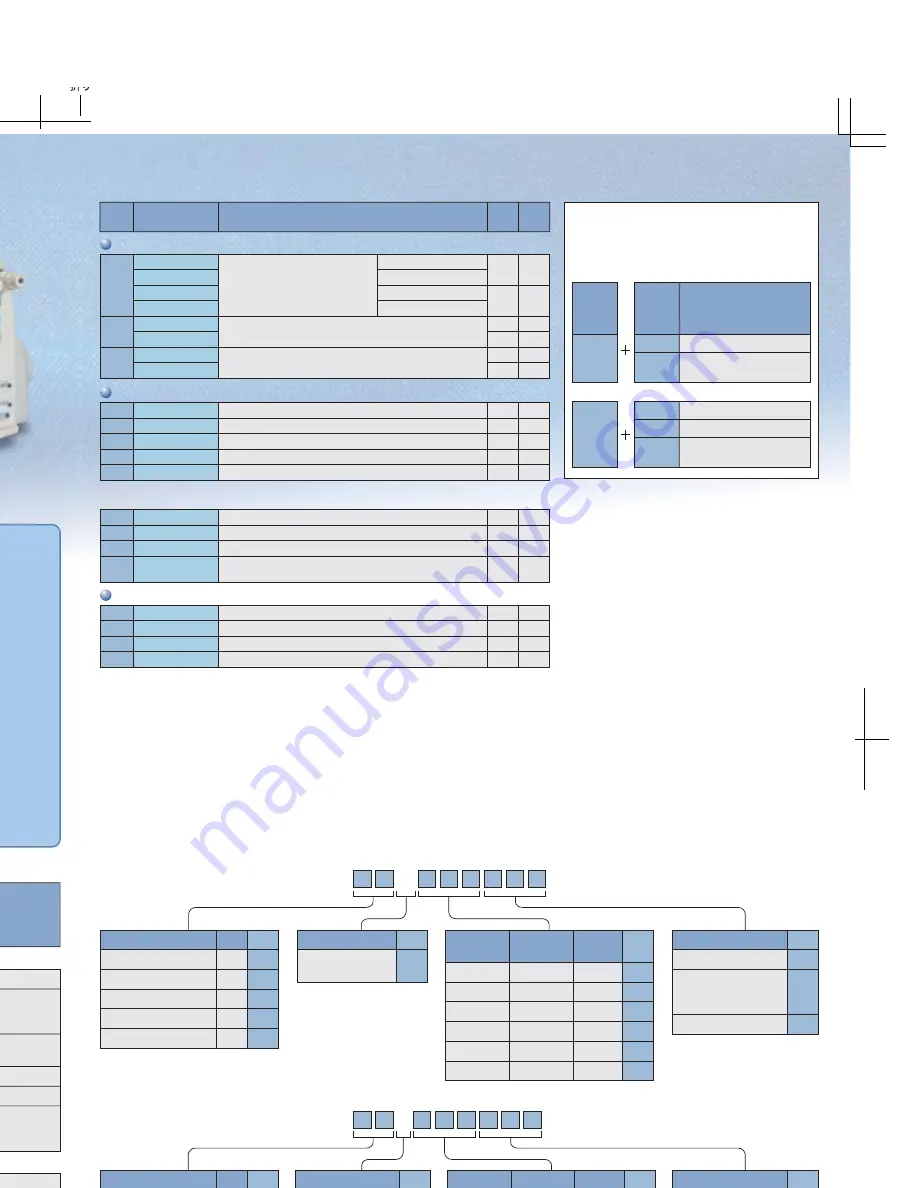

SUBCLASS MACHINE LIST

MO-6903G-0N6-3D1

L

〜

M

1

2

−

18.0

3

7

−

−

5

DO

×

5 #16 5,500 For splicing fabrics

MO-6904G-0F6-700

1

3

−

4.8

3

5

1:0.7

〜

1:1.75

−

8

DO

×

5 #21 6,000

For runstitching

extra heavy- weight

materials such as denim

MO-6905G-0M6-700

1

3

−

10.0

3

7

−

−

7

DC

×

1 #24 4,000

For overedging carpets,

mats for entrance halls, etc.

MO-6905G-0M6-7E0

EH

1

3

−

10.0

3

7

−

−

7

DC

×

1 #24 4,000 For overedging car mats

MO-6914G-CH6-700

2

4

2.6

6.4

3

4

1:0.8

〜

1:2

−

8

DO

×

5 #18 6,000 For overedging jersey, etc.

MO-6916G-FF6-700

2

5

4.8

4.8

3

5

1:0.7

〜

1:1.75

−

8

DO

×

5 #21 6,000

MO-6916G-FH6-700

2

5

4.8

6.4

3

5

1:0.7

〜

1:1.75

−

8

DO

×

5 #21 6,000

MO-6904J-0F6-700

1

3

−

4.8

3

5

1:0.7

〜

1:1.75 2.7

〜

7

8

DO

×

5 #21 6,000

For runstitching

extra heavy- weight

materials such as denim

MO-6914J-CH6-700

EH

2

4

2.6

6.4

3

4

1:0.8

〜

1:2

2.7

〜

7

8

DO

×

5 #18 6,000 For overedging jersey, etc.

MO-6916J-FF6-700

2

5

4.8

4.8

3

5

1:0.7

〜

1:1.75 2.7

〜

7

8

DO

×

5 #21 6,000

MO-6916J-FH6-700

2

5

4.8

6.4

3

5

1:0.7

〜

1:1.75 2.7

〜

7

8

DO

×

5 #21 6,000

MO-6916J-FF6-70

3

2

5

4.8

4.8

3

5

1:0.7

〜

1:1.75 2.7

〜

7

8

DC

×

27 #16 6,000 For safety stitching bathrobe, etc.

For safety stitching extra

heavy-weight materials

such as denim

For safety stitching extra

heavy-weight materials

such as denim

■

DEVISES AND ATTACHMENTS

■

WHEN YOU PLACE ORDERS

Model

Part No.

Description

MO-

MO-

6900G 6900J

T039

MAT-039001A0

For 110, 115, 220, 240V

〇

−

MAT-039002A0

For 220, 380, 415, 440V

MAT-039003A0

For 110, 115, 220, 240V

−

〇

MAT-039004A0

For 220, 380, 415, 440V

T048

MAT-048010A0

Pneumatic flat cutter (for overlock stitch machine)

〇

−

MAT-048010B0

−

〇

T050

MAT-050010A0

Pneumatic flat cutter (for safety stitch machine)

〇

−

MAT-050010B0

−

〇

MC-4

−

Specific to chain-off thread, pedal-operated

〇

〇

MC-5

−

Specific to chain-off thread

〇

〇

MC-8

−

Pneumatic chain-off cloth chips

〇

〇

MC-9

−

Function of MC-8 + auto-lifter

〇

〇

MC-24

−

Pneumatic chain-off cloth chips

〇

〇

[Reference]

Combination table of “chain-off thread suction device”

and “auto-lifer” which correspond to “chain-off thread

trimming device”.

Chain-off

thread

trimming

device

T039

T041S

or

T042S

Chain-off

thread

suction

device

Auto-lifter

MC-8

AK101 (JUKI servomotor)

MC-9

−

(MC-9 is equipped

with auto-lifter.)

MC-4

−

MC-8

AK101 (JUKI servomotor)

MC-9

−

(MC-9 is equipped

with auto-lifter.)

One-touch type tape cutter and

chain-off thread trimming device

(electromagnetic type)

Chain-off thread trimming device

Pneumatic chain-off thread suction device

AK32

GAK-320000A0

Pneumatic type (knee-operated)

〇

〇

AK49

GAK-490000A0

Pneumatic type (pedal-operated)

〇

〇

AK52

GAK-520000A0

Pneumatic type (with chain-off thread suction device)

〇

〇

AK101 GAK-A01000A0

Pneumatic type (for servomotor)

〇

〇

Auto-lifter

−

PF-0552010-B0

Air regulator (F.R. unit asm.)

〇

〇

−

GMD-01080000

×

2 Fixing screw for F.R. unit asm.

〇

〇

−

F1021-003-000

Tube connector (male)

〇

〇

−

GAS-12063000

*

One-touch connector

*

Selection parts instead of the tube connector

〇

〇

*

The aforementioned devices are not equipped with air regulator. Please purchase the following

components when you need to regulate air pressure.

Model No.

Materials

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Overedging

width (mm)

Number

of

feed dog

rows

Stitch

length

(mm)

Presser

lifting

amount

(mm)

Needle system

Max.

sewing

speed

(sti/min)

Bottom

differential-

feed ratio

Remarks

Longitudinal

stroke

of top-feed

dog (mm)

MO-6916G

An advanced full-featured machine that

is ideally suited to the sewing of

extra heavy-weight materials.

Please note when placing orders, that the model name should be written as follows:

●

To order, please contact your nearest JUKI distributor.

Stitch type

U.S.A Code

For splicing fabrics

503

03

1-needle overlock

504

04

For overedging carpets

505

05

2-needle overlock

514

14

2-needle safety stitch

516

16

Stitch type

U.S.A Code

1-needle overlock

504

04

2-needle overlock

514

14

2-needle safety stitch

516

16

Remarks

Code

For splicing fabrics

3D1

For extra heavy-weight

materials

(jeans, car mats etc.)

700

For car mats

7E0

Remarks

Code

For extra heavy-weight

materials

(jeans, car mats etc.)

700

For extra heavy-weight

materials (bathrobe etc.)

70

3

Type

Code

Extra heavy-weight

materials

G

Type

Code

Variable top-feed for

extra heavy-weight

materials

J

Needle

Overedging

Feed dog Code

gauge (mm) width (mm)

–

18.0

3-row

0N6

–

4.8

3-row

0F6

–

10.0

3-row

0M6

2.6

6.4

3-row

CH6

4.8

4.8

3-row

FF6

4.8

6.4

3-row

FH6

Needle

Overedging

Feed dog Code

gauge (mm) width (mm)

–

4.8

3-row

0F6

2.6

6.4

3-row

CH6

4.8

4.8

3-row

FF6

4.8

6.4

3-row

FH6

MO69 G

MO69 J

MO-6916G-FH6-700

MO-6916J-FH6-700

●

The machine securely clamps the material

at the beginning of sewing as well as

smoothly sewing multi-layered parts of

the material to facilitate the sewing of

extra heavy-weight materials.

●

The MO-6900J Series comes with a newly-

developed feed mechanism that moves

the top and bottom feeds separately.

With its improved feeding capacity and

stronger cloth-biting force, the feed

mechanism prevents uneven material

feed when sewing extra heavy-weight

materials.

●

The machine incorporates mechanisms

that are both durable and reliable, such

as the needle bar mechanism, utilyzing

the upper and lower bushings, a

cartridge type oil filter and cooling fan.

●

The machine is equipped as standard

with a micro-lifter that helps reduce

operator fatigue. The micro-lifter is

designed to achieve optimum balance,

not only reducing noise and vibration

but also ensuring comfortable operation.

●

Needle thread heat remover and needle

cooler prevent stitching troubles during

times of high-speed sewing, thereby

contributing to upgraded seam quality.

●

The machine comes standard with

various adjusting mechanisms, such as

a micro-adjusting mechanism, all of

which can be easily adjusted to enable

the machine to perform sewing under

the best-suited conditions for any kind

of material.