−

57

−

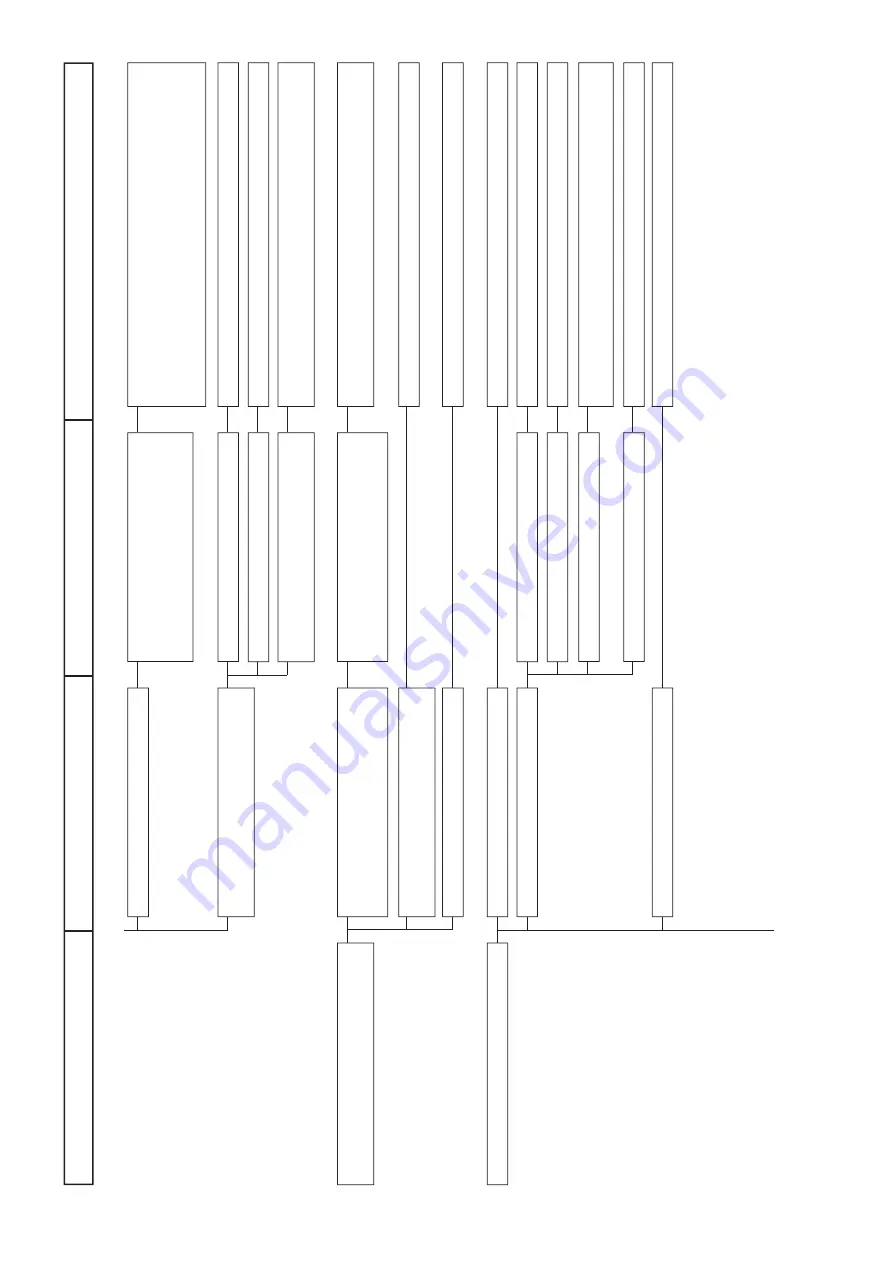

Troubles

Cause (1)

Cause (2)

Checking orders and corrective measures

From the previous page

Thread breaks when performing idle stitching

or jump stitching.

Uneven stitches

Hook timing is delayed.

Thread take-up spring is improperly

adjusted.

Same cause as [Thread breaks when

performing reverse feed stitching or back-

tack stitching]

Position of the knife thread guide is

improper.

Needle bar is positioned low.

Needle thread tension is too high.

Needle is defective.

Number of revolution is too high.

If the hook timing is delayed, needle thread

loop becomes too big and is deformed. As

a result, thread breakage occurs since the

blade point catches thread twice.

Stroke is too large or too small.

Tension is too high or too low.

Selection of the spring is improper for the

kind of thread.

Same cause as [Thread breaks when

performing reverse feed stitching or back-

tack stitching]

Needle is bent.

Top end of the needle is blunt.

Needle is too thin.

Needle is too long.

Adjust the hook in the state that the timing is earlier by 0.2 mm

than the lower marker line of needle bar.

Or, change the needle bar to needle bar of 22886907. Interval of

the marker lines of needle bar of 22886907 is narrower by o.2

mm than that of the standard.

Adjust the stroke.

Adjust the tension.

In case of A type thread tension, replace the spring with the

standard one. (In case of thick thread of #60 or more)

Same adjustment as [Thread breaks when performing reverse

feed stitching or back-tack stitching]

Adjust so that needle drops in the center of the hole.

Raise the needle bar.

Decrease the tension.

Replace the needle.

Replace the needle.

Use a thick needle. Use the double-step needle in case of KN

needle (one step needle).

Use a short needle. Or, use a needle with long shank. (DAX1)

Decrease the number of revolution.

To the next page

▼