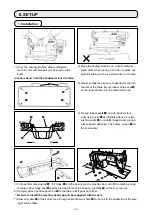

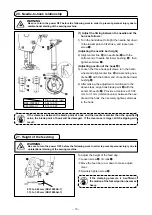

1) Adjust the amount of oil supplied to the thread

take-up and needle bar crank

❷

by turning adjust

pin

❶

.

2) The minimum amount of oil is reached when

marker dot

A

is brought close to needle bar crank

❷

by turning the adjust pin in direction

B

.

3) The maximum amount of oil is reached when

marker dot

A

is brought to the position just op-

posite from the needle bar crank by turning the

adjust pin in direction

C

.

minimum

maximum

❶

❷

A

B

C

❶

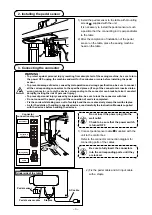

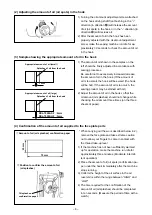

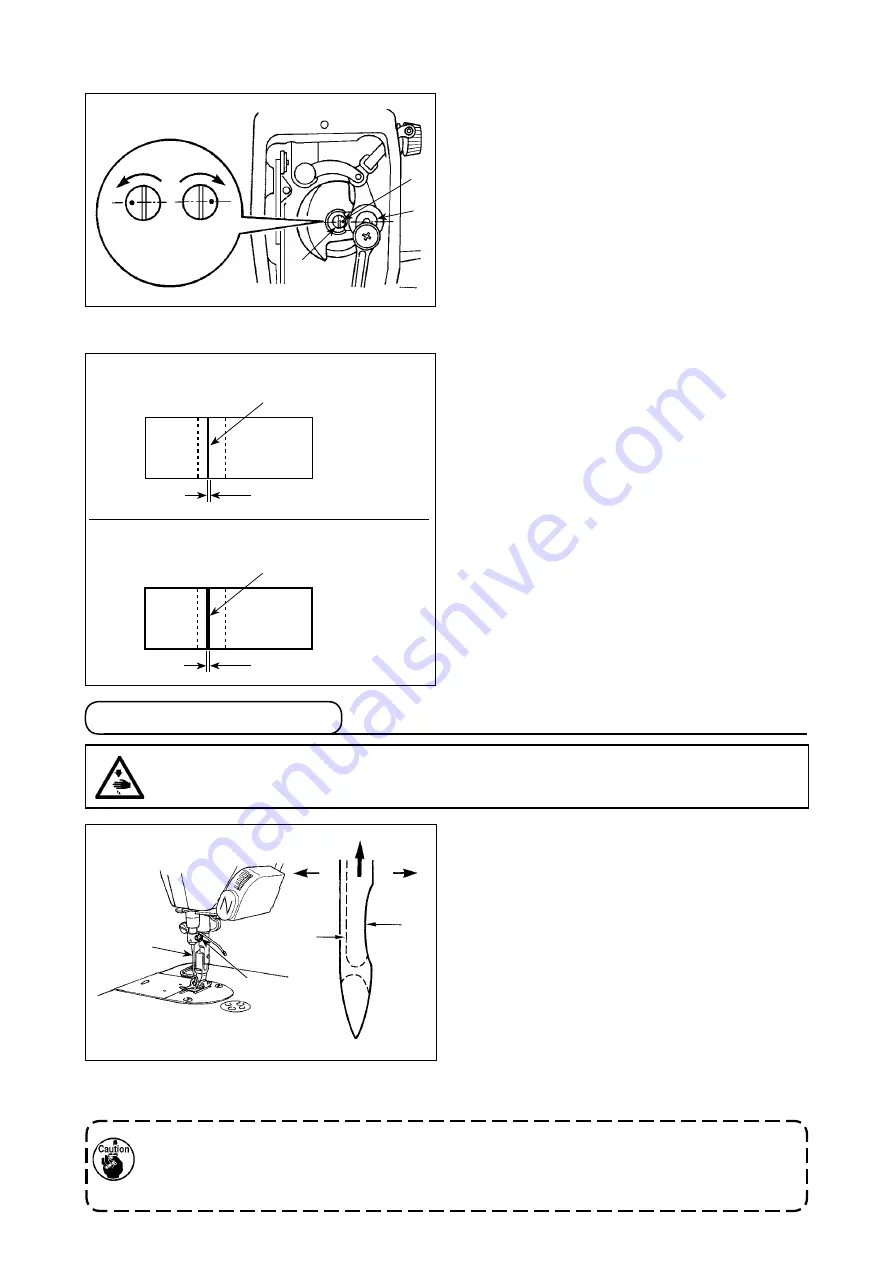

(6) Sample showing the appropriate amount of oil supplied to the face plate parts

1) The state given in the figure shows

the appropri-

ate amount of oil (oil splashes). It is necessary to

finely adjust the amount of oil in accordance with

the sewing processes. However, do not exces-

sively increase/decrease the amount of oil in the

hook. (If the amount of oil is too small, the hook

will be seized (the hook will be hot). If the amount

of oil is too much, the sewing product may be

stained with oil.)

2) Adjust the amount of oil in the hook so that the

oil amount (oil splashes) should not change while

checking the oil amount three times (on the three

sheets of paper).

Splashes of oil from the thread take-up lever

1 mm

Appropriate amount of oil (large)

Appropriate amount of oil (small)

2 mm

Splashes of oil from the thread take-up lever

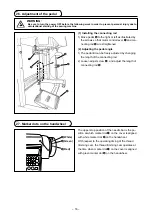

(5) Adjusting the amount of oil supplied to the face plate parts

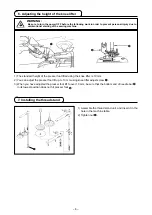

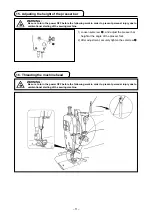

10. Attaching the needle

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

❷

C

D

B

A

Use the specified needle for the machine. Use the

proper needle in accordance with the thickness of

thread used and the kinds of the materials.

1) Turn the handwheel until the needle bar reaches

the highest point of its stroke.

2) Loosen screw

❷

, and hold needle

❶

with its in-

dented part A facing exactly to the right in direction

B.

3) Insert the needle fully into the hole in the needle

bar in the direction of the arrow until the end of

hole is reached.

4) Securely tighten screw

❷

.

5) Check that long groove C of the needle is facing exactly to the left in direction D.

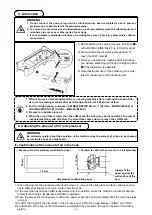

When polyester filament thread is used, if the indented part of the needle is tilted toward opera-

tor's side, the loop of thread becomes unstable. As a result, hangnail of thread or thread break-

age may occur. For the thread that such phenomenon is likely to occur, it is effective to attach

the needle with its indented part slightly slanting on the rear side.

– 9 –

Содержание DDL-7000A-7 Series

Страница 1: ...DDL 7000A 7 Series INSTRUCTION MANUAL ...