8

© Josef Kihlberg AB 2007

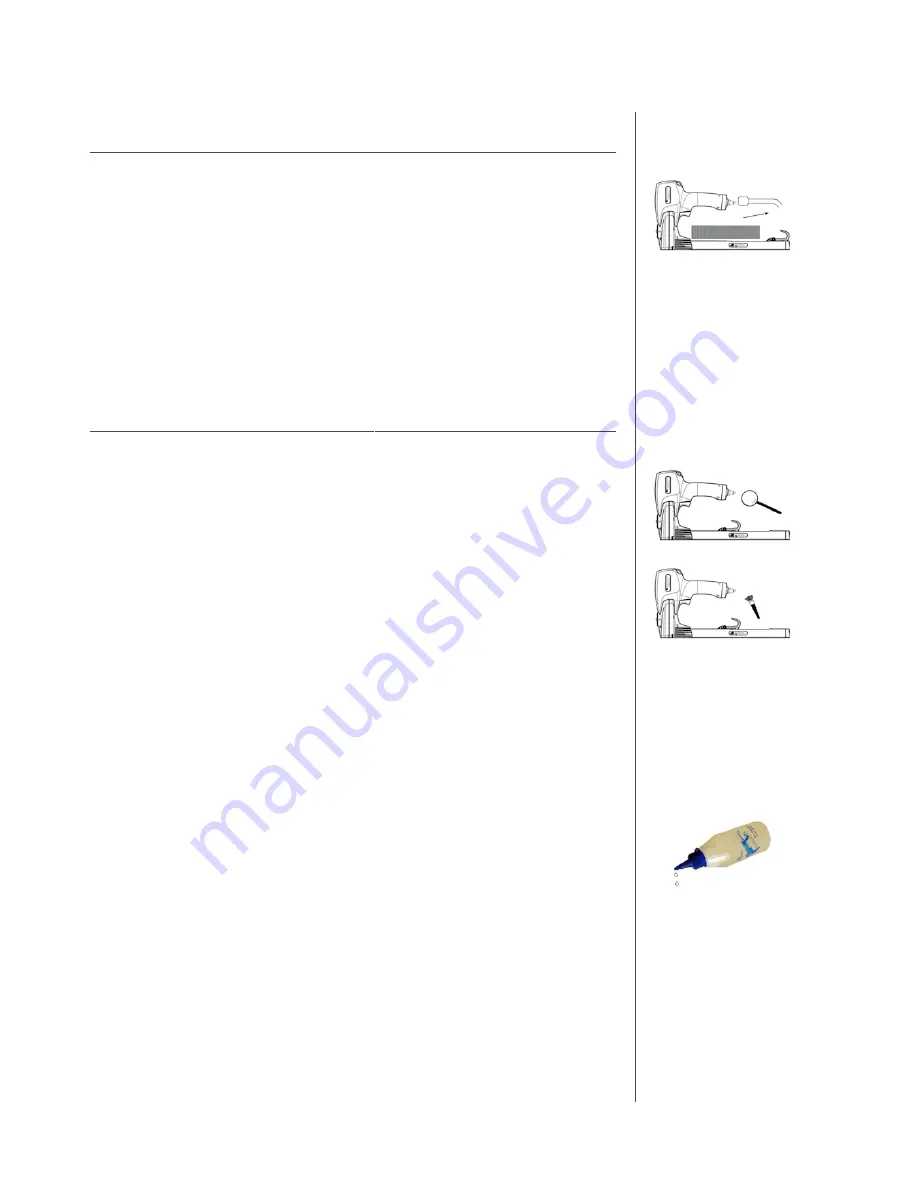

Troubleshooting

Always disconnect the tool from the air supply, empty the

magazine and read the

Safety precautions

section before

you begin troubleshooting. Normally it is not necessary to

dismantle any parts in order to remove a defective staple

from the front nozzle plate. Grip the staple with a pair of flat-

nosed pliers at the exit from the front nozzle plate. Carefully

pull out the staple.

All safety devices must be inspected daily to ensure that

they are working properly. Make especially sure that:

the trigger and safety yoke move freely without binding;

all screws and nuts are securely tightened.

This tool does not require special servicing. It only needs

regular cleaning with a non-aggressive cleaning agent. Do

not remove any parts for cleaning purposes.

Apply a small amount of lubricating oil to the nipple of the

tool every day or approximately 10 drops once a week to

maximize the life and utility of the tool. For high-frequency

stapling, we recommend oil-mist lubrication. Please contact

our agent for advice. Oil recommendation.

Part no.:

1 litre

184314

0.2 litre

733007

Sliding parts have been lubricated with multipurpose

grease at the factory. We recommend using multipurpose

grease on moving parts after they have been cleaned or

replaced.

•

•

Maintenance

EN