INSPECTION & START-UP CHECKLIST

A. RECEIVING & INSPECTION

Unit Received Undamaged

Unit Arrangement/Hand Correct

Unit Received Complete As Ordered

Unit Structural Support Complete & Correct

B. HANDLING & INSTALLATION

Unit Mounted Level & Square

Proper Electrical Service Provided

Proper Service Switch/Disconnect Provided

Proper Chilled Water Line Size To Unit

Proper Refrigerant Line Sizes To Unit

Proper Steam Condensate Trap On Return Line

All Services To Unit In Code Compliance

Proper Access Provided For Unit & Accessories

Proper Overcurrent Protection Provided

Confirm No Debris Is Left In The Electric Heat

Section

Proper Hot Water Line To Unit

Proper Steam Line Sizes To Unit

Proper Steam Supply Pressure To Unit (15psi Max)

All Shipping Screws & Braces Removed

Damper Linkage Is Tight And In Correct Position

Install Per Seismic IOM As Required

All Shipped Loose Parts Installed

Installer Has Cleaned Out Interior

Clean Air Filter Installed

C. COOLING/HEATING CONNECTIONS

Protect Valve Package Components From Heat

Connect Field Piping To Unit

Install Drain Line & Traps As Required

Install Condensate Pan Under Piping As Required

Mount Valve Packages

Pressure Test All Piping For Leaks

Insulate All Piping As Required

D. DUCTWORK CONNECTIONS

Install Ductwork, Fittings & Grilles As Required

Control Outside Air For Freeze Protection

Proper Supply & Return Grille Type & Size Used

Insulate All Ductwork As Required

Verify All Ductwork Is Complete, Dampers, And

Filters Are Installed Prior To Startup

E. ELECTRICAL CONNECTIONS

Refer To Unit Wiring Diagram

All Field Wiring In Code Compliance

Connect Incoming Power Service or Services

F. UNIT STARTUP

General Visual Unit & System Inspection

Record Ambient Temperature

Close All Unit Isolation Valves

Fill Systems With Water/Refrigerant

All Ductwork & Grilles In Place

Start Fans, Etc.

Check All Ductwork & Units For Air Leaks

Record All Final Settings For Future Use

Check All Dampers For Proper Operation

Verify Proper Heating Operation

Check All Piping For Leaks

Record Electrical Supply Voltage

Check All Wiring For Secure Connections

Flush Water Systems

Vent Water Systems As Required

All Unit Panels & Filters In Place

Check For Overload Condition Of All Units

Balance Air Systems As Required

Check Piping & Ductwork For Vibration

Verify Proper Cooling Operation

Reinstall All Covers & Access Panels

Check Unit Drain Pan To Confirm trap Is Free To

Drain And That Unit Drain Pan Does Not Hold Water

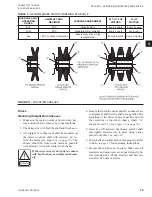

G. BLOWER / MOTOR

Check Sheave Set Screw Tightness

Check Blower Wheel Set Screw Tightness

Adjust Blower Speed as Necessary for Balancing

Airflow

Check / Adjust Belt Tension

Check / Adjust Sheave Alignment

Fan Wheel Properly Aligned, Tight On Shaft And

Freely Moving

Fan Bearing Have Been Re-Lubricated Properly

JOHNSON CONTROLS

17

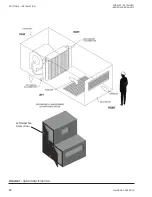

SECTION 2 - INSTALLATION

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013

2