Installation, Operation & Maintenance Instructions

4

API PLAN 74

SEAL SYSTEMS

ATTENTION

Before commencing the start-up procedure, review

and become familiar with all the available instructions

concerning the equipment, especially the safety

warnings.

a) Set the operating pressure to the ‘operating pressure’ on the

nameplate (typically 2 barg/30 psig greater than the process pressure)

by adjusting the regulator valve until the correct pressure is shown on

the pressure transmitter LCD (or pressure gauge if fitted). Turning the

regulator adjuster clockwise increases pressure and counter-clockwise

decreases pressure.

b) Purge the system of air by cracking open the vent connection (if fitted)

or by carefully cracking open the fitting at the seal and allowing barrier

gas to escape. After 10-15 seconds flow retighten the vent/fitting.

c) Recheck the operating pressure on the pressure gauge (if fitted) or

pressure transmitter LCD and fine tune if necessary.

d) Check that the pressure transmitter/switch and flow transmitter/

switch set points are correctly adjusted to suit the duty: Refer to the

table below.

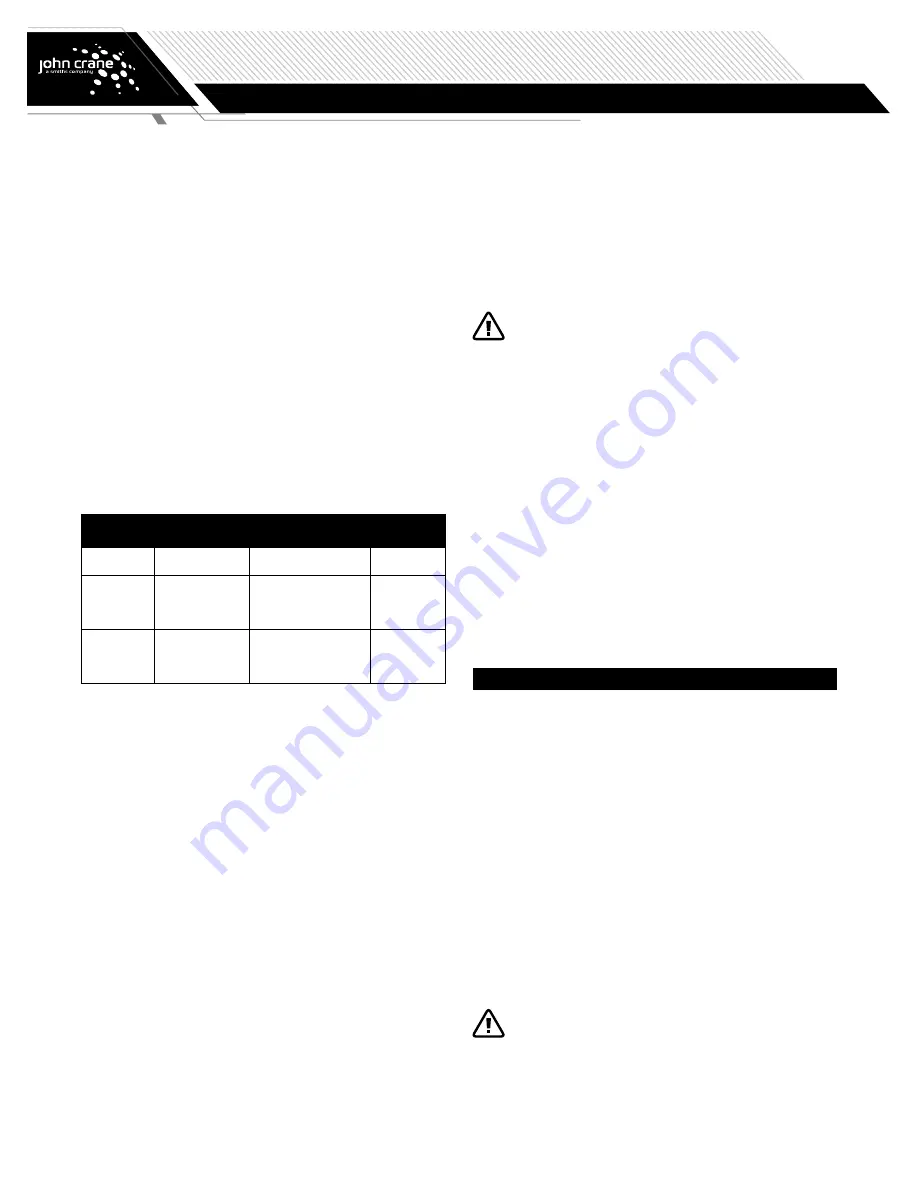

TABLE 1. Alarm Signals

Alarm Name

Instrument

Set Point

Notes

Low Pressure

/Shutdown

Required

Pressure Indicating

Transmitter (PIT) or

Pressure Switch (PS)

If barrier pressure drops

below the operating pressure

on the nameplate

REQUIRED

High Flow Alert

Flow Indicating

Transmitter (FIT) or

Flow Switch (FS)

If barrier flow rises

significantly above the value

indicated on the nameplate

RECOMMENDED

NOTE

High flow alarms are recommended as indicators of significant

deviations from normal running conditions; some fluctuation

is expected during operation. The alarm value on the

nameplate is normally several times larger than the normal

running value, and is set based on the limits of barrier gas

that can safely be injected into the machine.

e) Start the machine

f) During initial start-up it is recommended that the gas pressure/flow is

regularly monitored for correct operation. Fine tune pressure setting if

necessary.

6.2 Normal running

The equipment shall be kept clean and free from debris to allow ease

of access and reading of the instrumentation. Care should be taken to

prevent damage to the system from accidental knocks and/or exposure

to excessive sources or heat. Disconnection of any part of the system

should not be undertaken without the appropriate authorization and until

all pressure has been completely discharged and system allowed to

cool. All joints broken for maintenance should be plugged off to prevent

ingress of dirt.

During normal operation the only attention required is to monitor the

barrier gas flow. Periodic visual checking (at least every 48 hours) of the

pressure/flow within the system is recommended.

If the consumption rate of the barrier gas is low, this can result in a

phenomenon where the check valve closes fully and does not open

again until the pressure difference across the valve exceeds its cracking

pressure. This results in sudden increases in flow when the valve opens,

and then zero flow once it closes again, which will appear as pulsations

in the flow indicator/indicating transmitter. This is normal and does not

indicate a failure mode for the equipment. If the pulsations are large

enough to trigger high flow alarms, these alarm values may need to be

raised to avoid nuisance alarms.

6.3 Decommissioning

Work on the seal or system must only be carried out

when the machine is stationary, depressurized, and

secured against any unforeseen start-up. Isolation from

connections to pressurization sources must be carried out.

Before carrying out any work on the seal or system, the equipment must

be shut down and the barrier region must be fully depressurized. Once

this has been done the barrier gas supply to the Plan 74 control panel

can be isolated.

Do not isolate the barrier gas supply before the pump is made

safe.

Once the barrier gas supply is isolated carefully vent any residual

pressure from the panel and interconnecting pipe work and drain of any

liquids before carrying out any maintenance.

If the pump/panel is to be removed cover any open tubing fittings/

connections to prevent contamination.

NOTE

It is recommended that a pressure test is carried out on

the system after any repair and before operation on the

equipment.

7. Maintenance

7.1 Routine maintenance

Check the following as part of regular site walk-around checks for

trouble-free operation:

•

Check the condition of the coalescing filter element for contamination

(see Section 7.2).

•

Barrier pressure. Compare with the operating pressure on the

nameplate.

•

Barrier flow. Compare with the normal flow rate observed.

•

Condition of alarm signals (see Section 7.3).

7.2 Filter

It is recommended that the element is checked after the first month

of operation and if no contamination is detected thereafter at 6-month

intervals.

Irrespective of visual condition it is recommended that the filter element

is replaced annually.

The filter bowl is pressurized and no attempt should be

made to remove it until the barrier gas supply has been

isolated and all residual pressure in the system safely

vented. Note that the machine must also be stopped and

depressurized before removing the barrier gas pressure.