Please note that whilst the Nano is extremely simple to maintain,

all work must be carried out by a competent person.

When removing checkerplate cover for maintenance purposes,

first switch off by depressing the emergency stop/battery isolator

button located at the base of the machine. Use appropriate

safety/personal protective equipment where necessary.

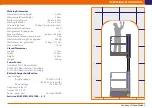

DAILY MAINTENANCE

Tilt cage by releasing gate latch on cage mount (see pic). Pull cage

frame from gate end and cage will lift and tilt assisted by gas strut.

Ensure gas strut is fully extended and that the safety chock is in place.

You can now access the powerpack housing. Unscrew the black

retaining knobs and lift out the checkerplate cover.

1.

Check Battery Electrolyte Level:

Remove battery cover and battery caps. Ensure the electrolyte

covers the plates by no more than 1mm – 2mm. Replenish with

distilled water to this level, only if the electrolyte level is below

the top of the plates.

2. Check Hydraulic Oil Level:

Ensure the tank is not overfilled. The level must only be checked

when the machine is in the transport position. The correct level

in this condition is approximately 3/4 from the base of the tank,

as indicated by the line.

3. Ensure there is no obvious mechanical damage

to the handrails,

entrance gate, post or structure of chassis. Also check the castors

and wheels are undamaged, rotate freely and are secured

to machine.

4. Check hydraulic connections

around the pump and base of

cylinder are tight and undamaged.

5. Check the spirit level

to ensure it is clearly legible and

undamaged.

6. Check all functions

operate correctly including movement alarm

and emergency stops.

7. Ensure mast surfaces are clean and not greased.

WEEKLY MAINTENANCE

Check battery terminal connections are tight.

MONTHLY MAINTENANCE

Check Battery Specific Gravity:

On a monthly basis check the specific gravity in each of the

battery cells. When a battery is correctly fully charged the

specific gravity should be 1.27 - 1.3. The specific gravity

reading should be equal across the cells, if not repeat the full

charge cycle.

Check rollers and mast surfaces for damage. Ensure brushes are fitted

correctly and brush against mast surface.

MAINTENANCE PROCEDURES

Cage mount

gate latch

Содержание Power Towers Nano

Страница 1: ...Operating and Maintenance Manual www powertowers com Courtesy of Crane Market...

Страница 21: ...Courtesy of Crane Market...

Страница 22: ...Courtesy of Crane Market...

Страница 23: ...Courtesy of Crane Market...