SECTION 2 - PREPARATION AND INSPECTION

1001070465

LIFTPOD by JLG

2-6

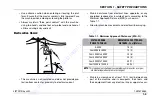

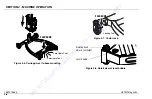

7. Rope Assembly

- Check rope is not frayed or damaged

(Figure 2-4.). Ensure it is tensioned tightly and seated

properly around take-up drum (view via carriage inspec-

tion window - see Figure 6-3.). Ensure it is seated cor-

rectly over mast-cap (Figure 2-5.) and at anchor point at

back of mast (Figure 2-6.). Indications that rope needs

replacement include:

1. Frayed or fluffy rope (Figure 2-4.)

2. Braiding no longer visible

3. Sections of rope thinned down in diameter.

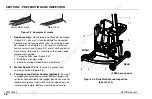

8. Manual Descent Crank

- Ensure it is present and

securely attached (Figure 2-8.).

9. Powerpack and Control Console (optional)

- Ensure it

is properly mounted and secured. Button, triggers and

switches not obscured or damaged; decals secure and

legible; emergency stop switch reset for operation; con-

trol markings legible. Battery is installed and secure.

Figure 2-2. Examples of cracks

Parent Metal Crack

Weld Crack

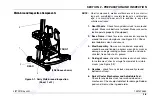

Figure 2-3. Daily Walk-Around Inspection

(Sheet 2 of 2)

5

7

9

10

8

FRONT

REAR

11

6

(FS80 base shown)

Go to Discount-Equipment.com

to order your parts