SECTION 2 - PROCEDURES

3120863

– JLG Lift –

2-11

2.9

CYLINDER REPAIR

NOTE:

The following are general procedures that apply to

all of the cylinders on this machine. Procedures that

apply to a specific cylinder will be so noted.

NOTE:

See Figure 2-5., Figure 2-6., Figure 2-7., and Figure

2-8. for the breakdown of typical hydraulic cylinders

used on this machine.

Disassembly

DISASSEMBLY OF THE CYLINDER SHOULD BE PERFORMED ON

A CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1.

Connect a suitable auxiliary hydraulic power source

to the cylinder port block fitting.

DO NOT FULLY EXTEND THE CYLINDER TO THE END OF THE

STROKE. RETRACT THE CYLINDER SLIGHTLY TO AVOID TRAP-

PING PRESSURE.

2.

Operate the hydraulic power source and extend the

cylinder. Shut down and disconnect the power

source. Adequately support the cylinder rod, if appli-

cable.

ON CYLINDERS WITH DOUBLE HOLDING VALVES, BEFORE

REMOVING HOLDING VALVES, CRACK THE BLEEDERS TO

RELEASE PRESSURE.

3.

If applicable, remove the cartridge-type holding

valve and fittings from the cylinder port block. Dis-

card the o-rings.

NOTE:

Step 4 applies only to the Telescope Cylinder.

4.

Remove the nuts which attach each cylinder rod

support block pull rod and withdraw the rods from

the forward end of the telescope cylinder.

5.

Place the cylinder barrel into a suitable holding fix-

ture. Tap around the outside of the cylinder head

retainer with a suitable hammer to shatter the loctite

seal.

6.

Using a suitable spanner wrench, loosen the cylin-

der head retainer, if applicable, and/or cylinder head

gland, and remove from cylinder barrel.

7.

Attach a suitable pulling device to the cylinder rod

port block end or cylinder rod end, as applicable.

EXTREME CARE SHOULD BE TAKEN WHEN REMOVING THE CYL-

INDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD OFF-

CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON AND

CYLINDER BARREL SURFACES.

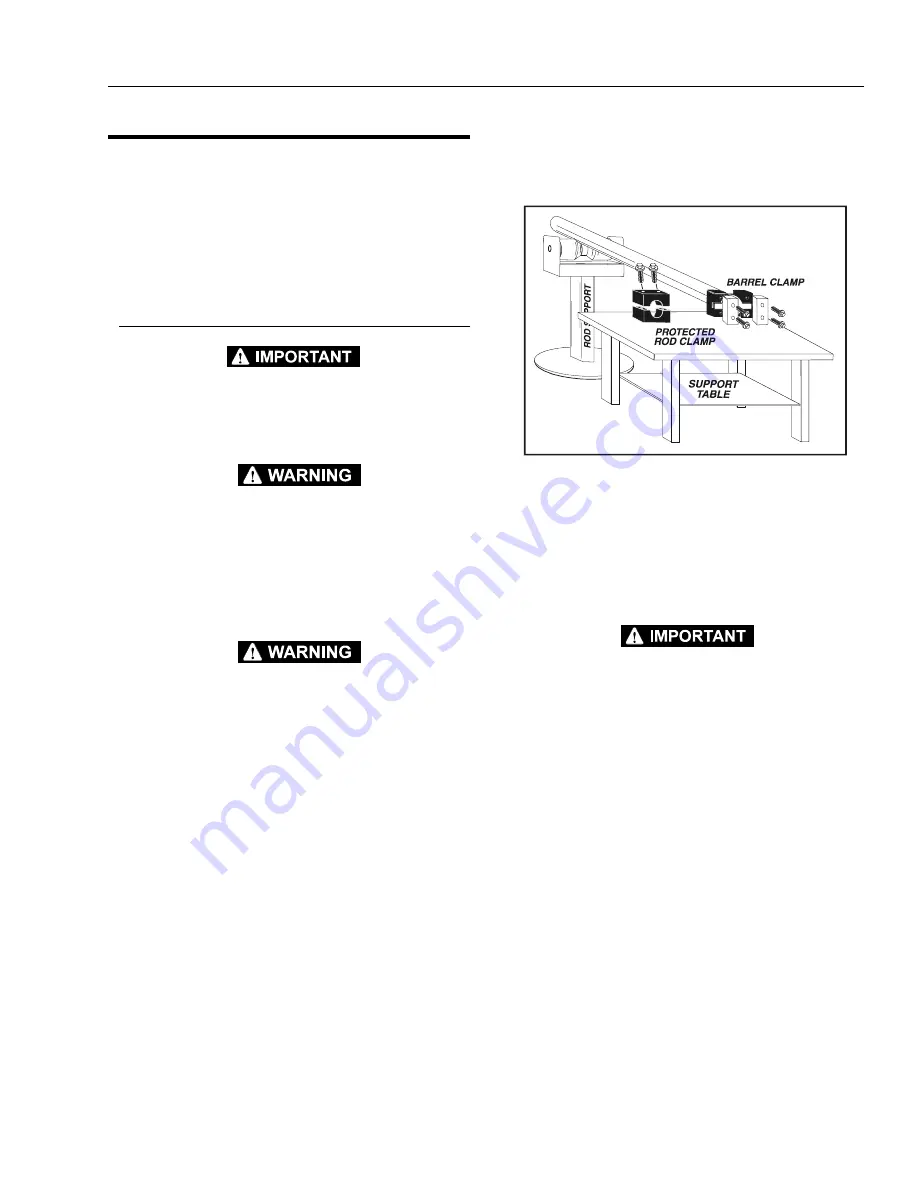

8.

With the barrel clamped securely, apply pressure to

the rod pulling device and carefully withdraw the

complete rod assembly from the cylinder barrel.

Figure 2-4. Cylinder Barrel Support

Содержание 80HX

Страница 2: ......

Страница 10: ...vi JLG Lift 3120863 TABLE OF CONTENTS Continued THIS PAGE LEFT BLANK INTENTIONALLY...

Страница 16: ...SECTION 1 SPECIFICATIONS 1 6 JLG Lift 3120863 Figure 1 2 Lubrication Diagram...

Страница 27: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 5 Figure 2 1 Proportional Control Valve...

Страница 34: ...SECTION 2 PROCEDURES 2 12 JLG Lift 3120863 Figure 2 5 Typical Hydraulic Cylinders Sheet 1 of 4...

Страница 35: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 13 Figure 2 6 Typical Hydraulic Cylinders Sheet 2 of 4...

Страница 36: ...SECTION 2 PROCEDURES 2 14 JLG Lift 3120863 Figure 2 7 Typical Hydraulic Cylinders Sheet 3 of 4...

Страница 37: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 15 Figure 2 8 Typical Hydraulic Cylinders Sheet 4 of 4...

Страница 44: ...SECTION 2 PROCEDURES 2 22 JLG Lift 3120863 Figure 2 12 Boom Assembly Sheet 1 of 2...

Страница 45: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 23 Figure 2 13 Boom Assembly Sheet 2 of 2...

Страница 53: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 31 Figure 2 16 Adeco Actuator Adjustments F4L912...

Страница 59: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 37 Figure 2 22 Pressure Setting All Hydraulic Machines Sheet 1 of 4...

Страница 60: ...SECTION 2 PROCEDURES 2 38 JLG Lift 3120863 Figure 2 23 Pressure Setting All Hydraulic Machines Sheet 2 of 4...

Страница 61: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 39 Figure 2 24 Pressure Setting All Hydraulic Machines Sheet 3 of 4...

Страница 62: ...SECTION 2 PROCEDURES 2 40 JLG Lift 3120863 Figure 2 25 Pressure Setting All Hydraulic Machines Sheet 4 of 4...

Страница 64: ...SECTION 2 PROCEDURES 2 42 JLG Lift 3120863 Figure 2 27 Solenoid Valve Pressure Settings 4 Wheel Steer...

Страница 65: ...SECTION 2 PROCEDURES 3120863 JLG Lift 2 43 Figure 2 28 Extend A Reach Valve Pressure and Speed Settings...

Страница 68: ...SECTION 2 PROCEDURES 2 46 JLG Lift 3120863 Figure 2 32 Swing Bearing Torquing Sequence...

Страница 70: ...SECTION 2 PROCEDURES 2 48 JLG Lift 3120863 Figure 2 33 Torque Hub Assembly...

Страница 78: ...SECTION 2 PROCEDURES 2 56 JLG Lift 3120863 Figure 2 34 Drive Brake Ausco Machines Built Prior to 1992...

Страница 80: ...SECTION 2 PROCEDURES 2 58 JLG Lift 3120863 Figure 2 35 Drive Brake Mico Machines Built from 1992 to Present...

Страница 108: ...SECTION 3 TROUBLESHOOTING 3 20 JLG Lift 3120863 Figure 3 1 Wiring Schematic Sheet 1 of 4...

Страница 109: ...SECTION 3 TROUBLESHOOTING 3120863 JLG Lift 3 21 Figure 3 2 Wiring Schematic Sheet 2 of 4 1870003A...

Страница 110: ...SECTION 3 TROUBLESHOOTING 3 22 JLG Lift 3120863 Figure 3 3 Wiring Schematic Sheet 3 of 4...

Страница 111: ...SECTION 3 TROUBLESHOOTING 3120863 JLG Lift 3 23 Figure 3 4 Wiring Schematic Sheet 4 of 4 1870003A...

Страница 112: ...SECTION 3 TROUBLESHOOTING 3 24 JLG Lift 3120863 Figure 3 5 Hydraulic Schematic Sheet 1 of 6...

Страница 113: ...SECTION 3 TROUBLESHOOTING 3120863 JLG Lift 3 25 Figure 3 6 Hydraulic Schematic Sheet 2 of 6 2792231...

Страница 114: ...SECTION 3 TROUBLESHOOTING 3 26 JLG Lift 3120863 Figure 3 7 Hydraulic Schematic Sheet 3 of 6...

Страница 115: ...SECTION 3 TROUBLESHOOTING 3120863 JLG Lift 3 27 Figure 3 8 Hydraulic Schematic Sheet 4 of 6 2792231...

Страница 116: ...SECTION 3 TROUBLESHOOTING 3 28 JLG Lift 3120863 Figure 3 9 Hydraulic Schematic Sheet 5 of 6...

Страница 117: ...SECTION 3 TROUBLESHOOTING 3120863 JLG Lift 3 29 Figure 3 10 Hydraulic Schematic Sheet 6 of 6 2792231...

Страница 118: ...SECTION 3 TROUBLESHOOTING 3 30 JLG Lift 3120863 This page left blank intentionally...

Страница 119: ......