SECTION

4

- BOO

M

& PLATFOR

M

4-48

3121160

4.16 FOOT SWITCH ADJUSTMENT

Adjust so that functions will operate when pedal is at center of

travel. If switch operates within last 1/4 in. (6.35 mm) of travel,

top or bottom, it should be adjusted.

4.17 UPRIGHT MONITORING SYSTEM

The UMS provides a visual and audible warning to the operator

when the limits of the upright assembly alignment have been

reached. In addition, the UMS will not allow the tower boom to

be lowered when the upright assembly is misaligned in a direc-

tion oriented away from the work platform.

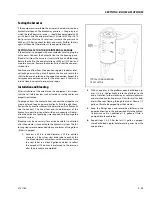

Re-Synchronizing Upright

A pull type control valve allows the operator to adjust the

upright level cylinder if the upright is not 90° (vertical) relative to

the chassis (Refer to Figure 4-26.). This valve is located in the tank

compartment area.

Perform the following steps with the aid of an assistant:

1.

Turn the key switch to the ground control position.

2.

Start the engine.

3.

Pull and hold the red relevel knob located next to the

main control valve. Refer to Figure 4-25.

4.

Raise the tower boom 6 feet (1.8 m).

5.

Release the red relevel knob.

6.

Lower the tower boom fully and continue to hold down

the switch to Tower Down for an additional 20 seconds.

7.

Repeat steps 3 thru 6 as necessary until the upright is

90° (vertical) relative to the chassis.

Table 4-2. Ramp Current Setting Range.

FUNCTION

MINIMUM

CURRENT

MAXIMUM

CURRENT

MAIN LIFT UP

450 to 550 mA

1300 to 1500 mA

MAIN LIFT DOWN

450 to 550 mA

1700 to 2000 mA

(Set 450 mA higher than

Main lift)

SWING RIGHT

450 to 550 mA

1000 to 1300 mA

SWING LEFT

450 to 550 mA

1100 to 1300 mA

(Set 100 mA higher than

swing right)

FLOW CONTROL

750 to 850 mA

1100 to 1300MA

(Set using Main Tele)

DRIVE FORWARD

20 to 60 mA

130 to 160 mA

DRIVE REVERSE

20 to 60 mA

130 to 160 mA

Table 4-3. Ramp time Setting.

FUNCTION

RAMP TIME

Lift Up

Ramp UpTime = 5:00 sec.

Ramp Down Time = 3:00 sec.

Lift Down

Ramp Up Time =5:00 sec.

Ramp Down Time =3:00 sec.

Swing Right

Ramp Up Time =7:00 sec.

Ramp Down Time =3:00 sec.

Swing Left

Ramp Up Time =7:00 sec.

Ramp Down Time =3:00 sec.

Drive Forward

Ramp Up Time =4:30 sec.

Ramp Down Time = 2:30 sec.

Drive Reverse

Ramp Up Time = 4:30 sec.

Ramp Down Time = 2:00 sec.

Flow Control

Ramp Up Time =3:00 sec.

Ramp Down Time =0.00 sec.

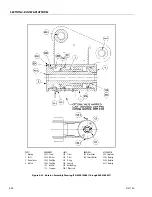

Figure 4-24. Control Card

Figure 4-25. Releveling Valve

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

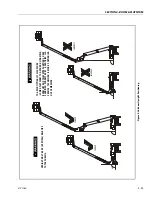

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

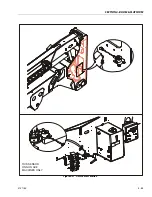

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......