11

EN

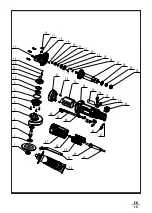

GENERAL DESCRIPTIONS

The product features refers to the illustration of the

machine on the graphics page.

1

2

3

8

9

4

5

6

7

1.spindle-lock button

2.spindle

3.mounting flange

4.ventilation slots

5.On/off locking switch

6.auxiliary handle

7.protective guard

8.Clamping flange

9.spanner

INSTRUCTIONS FOR OPERATION

CAUTION:

Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

●

Operation of Spindle Lock

Never actuate the spindle lock when the spindle is

moving. The tool may be damaged.

Press the spindle lock to prevent spindle rotation

when installing or removing accessories.

1

1.Spindle Lock

●

Operation of Switch

When you press the rear of the button and push the

button forward to the "0" position, the tool can be

started. Then, press the front part of the button to

lock the switch button, press the rear of the switch

button, the switch will automatically reset to the "1"

position, the tool stops rotating.

CAUTION:

Before plugging in the tool, always check to see

that the switch actuates properly and returns to the

“OFF” position when the rear of the switch lever is

depressed.

1.Press

2.Push

3.Switch Lever

4.On:1.Press

2.Push

Off:Press

1

2

3

4

●

Installing or Removing the Wheel Guard

CAUTION:

The wheel guard must be installed on the tool so that

the closed side always points toward the operator.

Mount the wheel guard with the protrusion on the

wheel guard band aligned with the notch on the gear

housing cover. Then rotate the wheel guard to an

angle that can protect the operator according to the

actual work. Be sure to tighten the screws.

To remove the wheel guard, follow the installation

procedure in reverse.

1.Outer Flange

2.Grinding Wheel or

Flap Disc

3.Inner Flange

4.Drive spindle

4

3

2

1

Warnings

:

●When using an abrasive cut-off wheel, be sure to

use only the special wheel guard designed for use

with cut-off wheels.

●Never use cut-off wheel for side grinding.

●Do not "jam" the wheel or apply excessive pressure.

Do not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the

cut and the possibility of kickback, wheel breakage

and overheating of the motor may occur.

●Do not start the cutting operation in the workpiece.

Let the wheel reach full speed and carefully enter into

the cut moving the tool forward over the workpiece

surface. The wheel may bind, walk up or kickback if

the power tool is started in the workpiece.

●During cutting operations, never change the angle

of the wheel. Placing side pressure on the cut-off

wheel (as in grinding) will cause the wheel to crack

and break, causing serious personal injury.