11

5. Raise belt tension lever to tighten belt against

the wheels. Tighten belt until it is just taut. Do

not over-tension the abrasive belt. A moderate

tension will provide faster cutting, longer belt

life, and better tracking.

Excessive belt tension will

reduce belt life and cause excessive wear of

contact wheel bearings.

Belt tension should

only be sufficient to allow proper tracking.

6. Check belt tracking; see

sect. 7.4

.

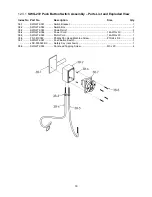

Figure 7-2: belt replacement

7.4

Belt tracking

Do not operate machine with

side panel open.

1. Loosen knob and raise upper guard. Open side

panel by turning its knob.

2. Spin drive wheel by hand and check tracking of

belt. If belt tracks to right or left, adjustment is

required.

3. Turn idler adjust screw (Figure 7-3) clockwise to

cause belt to track right. Turn idler screw

counterclockwise to cause belt to track left.

Perform this in small increments and allow belt

to respond to the changes.

4. Close side panel and secure by turning knob on

panel. Lower upper belt guard and secure with

knob.

5. Turn on grinder. Check belt tracking; belt should

remain centered on contact wheel. Make further

adjustments as needed according to step #3.

6. If belt still does not track properly, increase belt

tension and repeat steps 1 through 5.

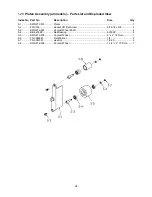

Figure 7-3: Belt tracking

8.0

Operation

8.1

Controls

8.1.1

Variable speed model (SWG-272VS)

To activate machine, lift the red switch cover and

pull up the toggle switch to start the machine. To

stop, simply push down the red cover.

Press on/off button on keypad (Figure 8-1) to start

or stop belt action. Press any of the numbered

buttons to start machine at the designated speed.

Press arrow buttons to change rotation speed in 100

RPM increments.

The digital readout displays RPM (revolutions per

minute), and will flash briefly during start up and

speed adjustments.

The control panel will automatically shut off after 10

minutes of inactivity.

Figure 8-1: variable speed control