12

Emptying the Collector Bag

CAUTION

Wearing a particle mask/respirator for

protection against fine dust particles during

cleaning is highly recommended.

During first use and after cleaning, the bag may

allow some dust to escape. This is normal and

will stop after a short period of time.

Clean the collector bag frequently to keep the

collector's performance at its optimum. To

clean:

1. Disconnect the machine from the power

source, unplug.

2. Remove the collector bag from the hanger

rods.

3. Loosen the ring clamp and remove the bag.

4. Empty the contents into an appropriate

container. The bag is easily emptied by

unzipping the bottom of the bag.

Optional Accessories

57620025: JET Stik Abrasive Belt and Disc

Cleaner.

JDS-12B Sanding Disc PSA Aluminum Oxide

“J” Weight Cloth Back.

12”

36 Grit

50 Grit

60 Grit

Stock

Number

57698525 57698650 57698750

Master

Carton

25 50 50

12”

80 Grit

100 Grit

120 Grit

Stock

Number

57698850 57698950 57699050

Master

Carton

50 50 50

Troubleshooting

Trouble Possible

Cause Solution

Sander will not start

1. Sander unplugged from wall

or motor

2. Fuse blown or circuit breaker

tripped

3. Cord

damaged

1. Check all plug connections

2. Replace fuse or reset circuit

breaker

3. Replace

cord

Sanding disc does not come

up to speed

1. Extension cord too light or

too long

2. Low

current

1. Replace with adequate size

and length cord

2. Contact a qualified

electrician

Machine vibrates excessively

1. Stand or base on uneven

surface

1. Adjust stand or base so that

it rests evenly on the floor

2. Bolt

down

Sanded edge not square

1. Table not square to sanding

disc

1. Use a square to adjust table

to sanding disc

Sanding marks on wood

1. Work held still

2. Wrong grit sanding disc

3. Feed pressure too great

4. Sanding against the grain

1. Keep workpiece moving

2. Use coarser grit for stock

removal and fine grit for

finish sanding.

3. Never force workpiece

4. Sand with the grain

Содержание PDS-12CS

Страница 13: ...13 Base Assembly Breakdown...

Страница 15: ...15 Sander Assembly Breakdown...

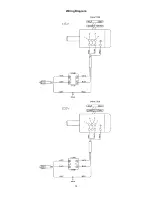

Страница 18: ...18 Wiring Diagram...