14

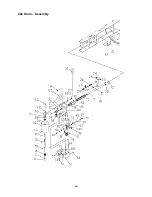

Motor Mount Tracking Adjustment

Referring to Figure 14:

The OES-80CS comes with tracking adjustment

bolts (A) on the motor plate. These are set at the

factory and should not require any further

adjustment. If, however, you are not able to track

the belt with the

Belt Tracking Adjustment

described in the previous section, the motor mount

bolts will have to be adjusted.

Note:

The

Motor Mount Tracking Adjustment

is a

course

adjustment. Use the

Belt Tracking

Adjustment

first for

fine

adjustment. If it cannot be

adjusted,

then

use the procedure described below.

To adjust:

1. Disconnect the machine from the power

source.

2. Slightly loosen the four

motor mount nuts

(B)

just enough so the

tracking screws

(A) can be

turned to make an adjustment.

3. Loosen the two

locking hex nuts

(C) that

secure the

tracking screws

(A).

4. Turn one

screw

(A) a 1/4 turn and rotate the

sanding belt by hand to observe which

direction the adjustment is causing the belt to

move. If it is traveling in the direction needed

to correctly track the belt go to step 6.

5. If the belt starts to travel in the wrong direction,

back off a quarter turn and

tighten the other

screw

a quarter turn. This should start the belt

moving in the proper direction.

6. Tighten

both

locking nuts

(C) and

motor mount

nuts

(B). Then return to the Belt Tracking

Adjustment section (previous page) and again

attempt to fine tune the tracking.

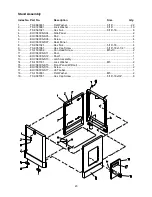

Table Adjustment

Do not position table below

sanding belt! Keep an overlap of at least 1/16”

between table and sanding belt to avoid

material and/or fingers getting caught! Failure

to comply may cause serious injury!

1. Loosen two lock knobs (A, Fig. 15).

2. Raise or lower work table to desired level.

3. Tighten two lock knobs.

Figure 14

Figure 15

Содержание OES-80CS

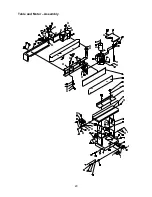

Страница 20: ...20 Table and Motor Assembly...

Страница 22: ...22 Idle Drum Assembly...

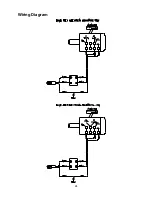

Страница 24: ...24 Wiring Diagram...