13

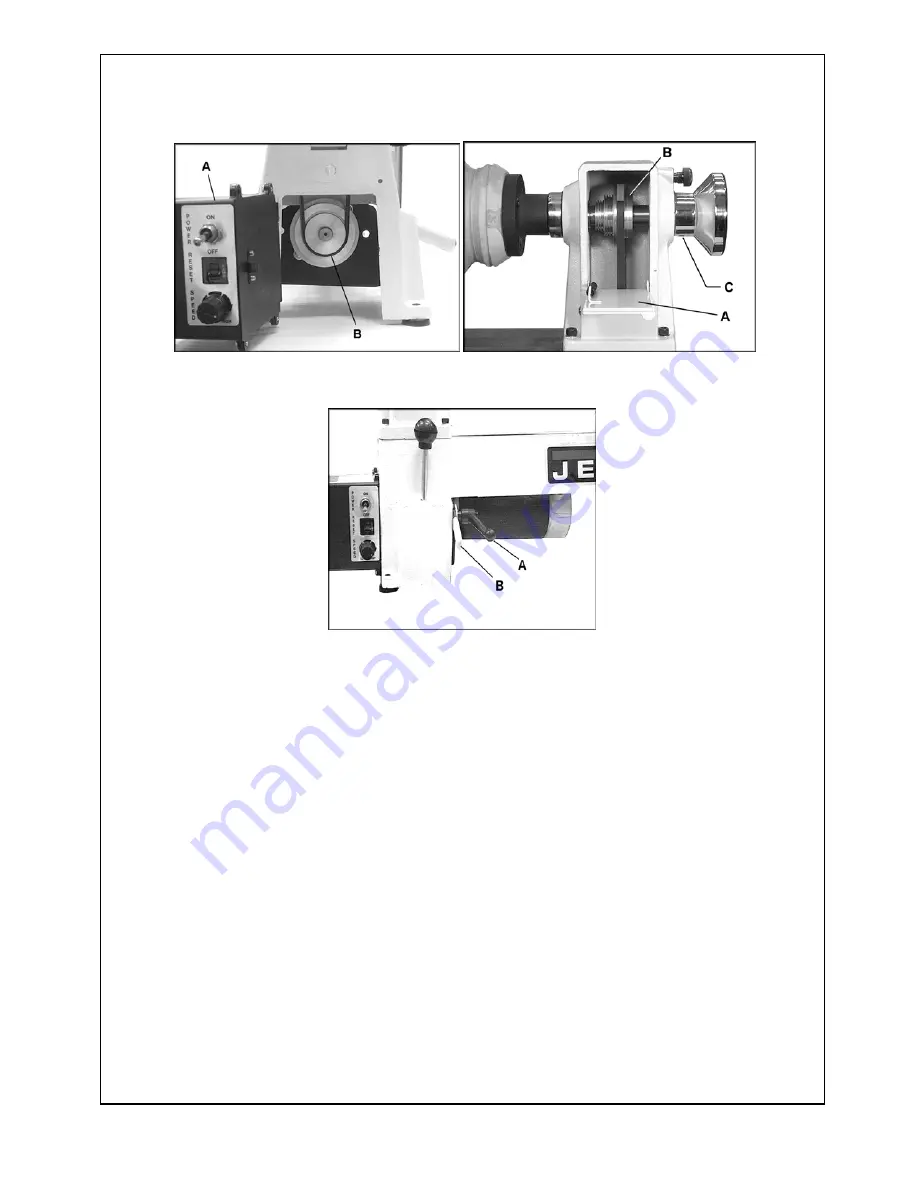

Figure 10 Figure 11

Figure 12

Changing Spindle Speeds

The variable speeds of the lathe are controlled by the speed knob on the control box as well as the

position of the belt on the pulleys.

1. Disconnect machine from the power source (unplug).

2. Pull open the control box at the left side of the base (A, Figure 10), and the access door at the back

side of the headstock (A, Figure 11) to expose the pulleys.

3. Loosen the motor plate lock handle (A, Figure 12). Lift up on the motor plate handle (B, Figure 12) to

take tension off the belt.

4. Move the belt (B, Figure 10) to the desired pulley groove according to the speed chart found on the

inside of the headstock access door. Be sure the belt is aligned with spindle pulley and motor pulley.

5. Tension the belt by pushing down on the motor plate handle (B, Figure 12) and lock in place.

Содержание JML-1014VSI

Страница 16: ...16 Parts Breakdown for JML 1014VSI Lathe ...

Страница 19: ...19 Electrical Connections JML 1014VSI ...

Страница 23: ...23 Electrical Connection for JWL 1220VS Lathe ...

Страница 24: ...24 WMH Tool Group 2420 Vantage Drive Elgin Illinois 60124 Phone 800 274 6848 www wmhtoolgroup com ...