14

9.0

Maintenance/Lubrication

Lathe must be serviced at all

lubrication points and all reservoirs filled to

operating level before the lathe is put into

service. Failure to comply may cause serious

damage to the lathe.

The ZH series lathe is shipped with oil in the

reservoirs. Coolant is not included.

Use clean lubricants and check levels often,

including before each working shift. To ensure

proper lubrication, oil levels should not be less than

the center of the oil sight glass. Try not to overfill,

as this may cause leakage.

A chart is supplied in

section 15.0

for quick

reference to all lubrication points.

Unless specified otherwise, the lubrication points

require a non-detergent, ISO 68, SAE 20W oil. The

recommended brand for this lathe is Mobil DTE

®

Oil Heavy Medium.

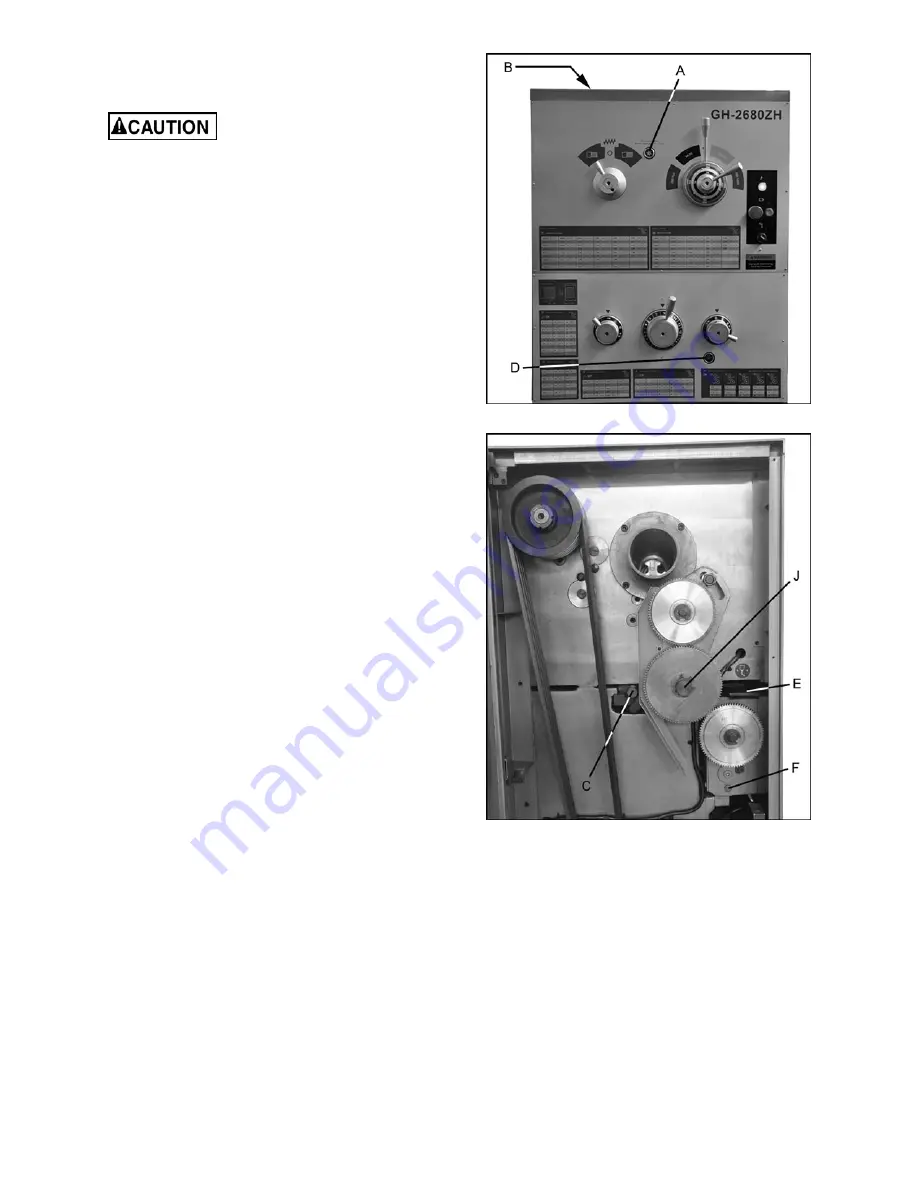

1.

Headstock

– Oil must be up to indicator mark

in oil sight glass at the

rear

of the headstock.

[NOTE: The sight glass on the

front

of the

headstock (A, Figure 8) verifies operation of

the oil pump, the one at

rear

of headstock (not

shown) indicates oil level]. Top off with SAE

20W oil. Fill by removing the rubber mat and

unscrewing the plug (B) on top of the

headstock.

2. To drain the headstock, remove the nut on the

drain pipe (C, figure 9). Drain oil completely

and clean out all metal shavings, then rinse

the casting case with kerosene. During the

breaking-in process for the lathe, the first oil

change should be after 10 days; the second

after 20 days. Then change the oil in the

headstock every three months.

Figure 8 – Headstock lubrication

Figure 9 – Lubrication points

3.

Oil Filter

– The filter should be cleaned once a

month. To access, open the top cover on the

headstock, unscrew the nut on the oil line, and

pull up the oil line to bring the filter up. See

Figure 10. Use a brush to clean.

Содержание GH-26120ZH

Страница 34: ...34 18 0 Change Gear Diagram Figure 54 ...

Страница 35: ...35 This page intentionally left blank ...

Страница 40: ...4 1 1 Bed Assembly I Exploded View ...

Страница 41: ...5 1 2 Bed Assembly I for 120 ZH only Exploded View ...

Страница 44: ...8 2 1 Bed Assembly II Exploded View ...

Страница 45: ...9 2 2 Bed Assembly II for 120 ZH only Exploded View ...

Страница 48: ...12 3 1 Headstock Assembly I Exploded View Ⅲ Ⅳ Ⅴ Ⅶ Ⅵ Ⅱ Ⅰ Ⅱb Ⅶb ZⅡ ZⅠ ZⅡ ...

Страница 51: ...15 4 1 Headstock Assembly II Exploded View ...

Страница 54: ...18 5 1 Headstock Assembly III Exploded View ...

Страница 56: ...20 6 1 Headstock Assembly IV Exploded View Ⅰ Ⅱb Ⅱ Ⅲ Ⅳ Ⅴ ...

Страница 59: ...23 7 1 Headstock Assembly V Exploded View Ⅶ Ⅶb Ⅵ ...

Страница 62: ...26 9 1 Gear Box Assembly I Exploded View Ⅱ Ⅲ Ⅰ ...

Страница 64: ...28 10 1 Gear Box Assembly II Exploded View ...

Страница 67: ...31 11 1 Gear Box Assembly III Exploded View ...

Страница 70: ...34 12 1 Brake Assembly Exploded View ...

Страница 72: ...36 13 1 Saddle and Cross Slide Assembly Exploded View ...

Страница 75: ...39 14 1 Tool Post and Compound Rest Assembly Exploded View ...

Страница 77: ...41 15 1 Apron Assembly I Exploded View Ⅱ Ⅹ Ⅱ Ⅲ Ⅷ Ⅹ Ⅸ Ⅹ Ⅳ Ⅰ Ⅹ Ⅰ Ⅵ Ⅲ Ⅴ Ⅶ ...

Страница 80: ...44 16 1 Apron Assembly II Exploded View Ⅺ Ⅹ Ⅲ Ⅻ Ⅸ Ⅹ Ⅶ ...

Страница 83: ...47 17 1 Apron Assembly III Exploded View Ⅰ Ⅱ Ⅴ Ⅲ Ⅳ Ⅵ ...

Страница 85: ...49 18 1 Apron Assembly IV Exploded View ...

Страница 87: ...51 19 1 Tailstock Assembly I Exploded View ...

Страница 89: ...53 20 1 Tailstock Assembly II Exploded View ...

Страница 91: ...55 21 1 Steady Rest Assembly Small and Large Exploded View ...

Страница 95: ...59 24 1 Travel Stop Assembly Exploded View ...

Страница 99: ...63 27 1 Electrical Components FR2 FR3 KM1 KM2 KM3 QF1 QF4 7 4 5 KA1 TC 2 3 11 10 1 QS 6 HL SB1 SB4 SA1 8 9 ...

Страница 100: ...64 27 2 Electrical Diagram ...