3

WARNING

1.

Read and understand the entire

instruction manual before attempting

assembly or operation.

2.

This sander is designed and intended for

use by properly trained and experienced

personnel only. If you are not familiar

with the proper and safe operation of a

sander, do not use until proper training

and knowledge have been obtained.

3.

Always wear approved safety glasses/face

shields while using this machine.

4.

Make certain the machine is properly

grounded.

5.

Before operating the machine, remove tie,

rings, watches, other jewelry, and roll up

sleeves above the elbows. Remove all

loose clothing and confine long hair. Do not

wear gloves.

6.

Keep the floor around the machine clean

and free of scrap material, oil and grease.

7.

Keep machine guards in place at all times

when the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately.

8.

Do not over reach. Maintain a balanced

stance at all times so that you do not fall or

lean against blades or other moving parts.

9.

Make all machine adjustments or

maintenance with the machine unplugged

from the power source.

10. Use the right tool. Don't force a tool or

attachment to do a job that it was not

designed for.

11. Replace warning labels if they become

obscured or removed.

12. Make certain the switch is in the OFF

position before connecting the machine to

the power supply.

13. Give your work undivided attention.

Looking around, carrying on a conversation,

and "horse-play" are careless acts that can

result in serious injury.

14. Keep visitors a safe distance from the work

area.

15. Use recommended accessories; improper

accessories may be hazardous.

16. Read and understand warnings posted on

the machine.

17. Failure to comply with all of these warnings

may cause serious injury.

18. Some dust created by power sanding,

sawing, grinding, drilling and other

construction activities contains chemicals

known to cause cancer, birth defects or

other reproductive harm. Some examples

of these chemicals are:

•

Lead from lead based paint

•

crystalline silica from bricks and cement

and other masonry products, and

•

arsenic and chromium from chemically-

treated lumber.

19. Your risk from those exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are

specifically designed to filter out

microscopic particles

20. Do not operate tool while under the

influence of drugs, alcohol or any

medication.

Содержание EHVS-80CS

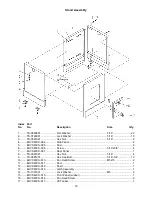

Страница 14: ...14 Table and Motor Assembly ...

Страница 19: ...19 ...