4

Read the entire contents of

this manual before assembling or operating the

taper attachment. Also, thoroughly familiarize

yourself with all operation, maintenance and

safety instructions that accompany the lathe to

which the taper attachment will be mounted.

Failure to comply may cause serious injury.

Assembly

Numbers in parentheses (#) correspond to Figures

and to index numbers in exploded view.

1. Carefully remove taper attachment from box.

Do not discard any packing material until taper

attachment is assembled and operating

properly. If any damage or missing parts are

identified, contact your distributor immediately.

2. Remove splash guard from lathe.

3. Remove two nuts (A, Figure 1) and bearing

cap (B, Figure 1) from end of cross slide screw

(C, Figure 1).

4. Remove the two thrust bearings from cross

feed screw.

5. Remove two hex socket cap screws (D, Figure

1) and the block (E, Figure 1). Set these items

aside; do not discard them.

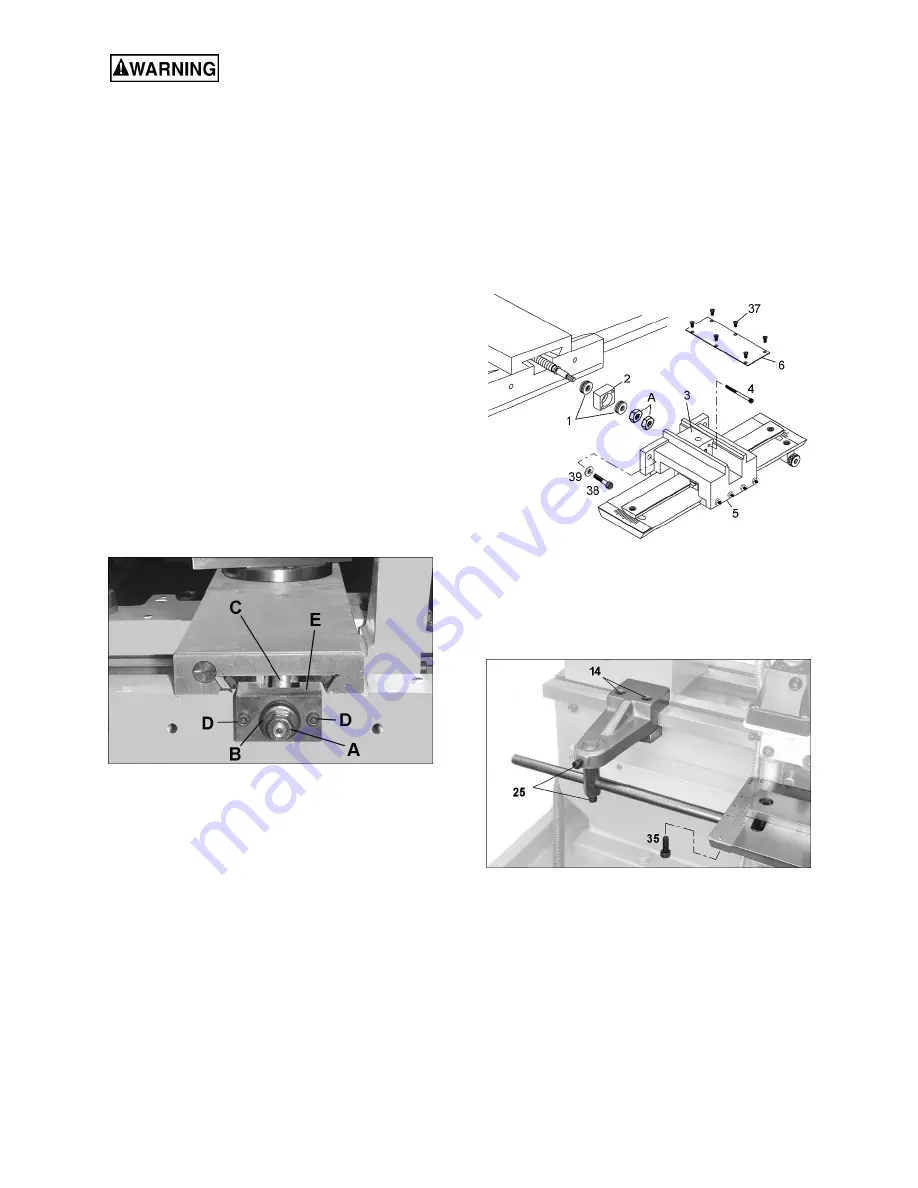

Figure 1

6. On the taper attachment, remove eight flat

head screws (#37) and remove cover (#6).

See Figure 2.

7. Loosen screws (#4) to separate yoke (#3) from

block (#2).

8. Install block (#2, with thrust bearings #1

installed) onto cross screw. See Figure 2.

9. Reinstall nuts (A, Figure 2) onto end of cross

screw. Tighten inner nut first to snug up

bearing assembly. Turn cross slide handle and

check for smooth rotation. Tighten outer nut to

secure the adjustment.

NOTE: It is recommended that two persons

perform the following steps, one to hold and help

align the taper attachment, the other to secure the

fasteners.

10. Hold taper attachment so that hole in yoke (#3)

aligns with cross screw. Secure yoke to block

(#2) with the two screws (#4).

NOTE: Top surface of block (#2) must be

even

with or lower than

top surface of yoke (#3). If

needed, rotate block (#2) 180-degrees to

achieve this position.

11. Attach base casting (#5) to predrilled holes in

carriage with M8x30 hex socket cap screws,

and flat washers (#38/39, Figure 2). Tighten

the cap screws enough to hold base in position

but loose enough to allow adjustment with

rubber mallet.

Figure 2

12. Install clamp to bedway, along with rod and

pivot, as shown in Figure 3. Secure rod to end

of slide base with screw (#35). Tighten screws

(#14,25,35)

Figure 3

13. Attach a dial indicator with magnetic base to

lathe bed (Figure 4), and level the longitudinal

slide to the bedway. The slide assembly is

level when deviation is less than 0.005” from

end to end. Use rubber mallet or dead blow

hammer to nudge base casting as needed,

until slide is level with bedways.