7

Now it is ready for extraction

Tips: ball Valve should be on the position off when only extract vacuum for the cylinder, in order to

have a view of the quality and quantity of the waste oil.

If extract to be vacuum for both measuring glass and tank

1.

According to the SAME first and second steps described in the previous steps.

2.

Open the valve

③

3.

Gradually turn on the air inlet valve for vacuum generation.

4.

When finger reaching to the MAX. area on the vacuum gauge, turn off the air inlet valve (estimated time

for vacuum generation within 4~5 minutes)

5.

Remove the pipe of air compressor.

6.

Now it is ready for extraction

Notice: Under a working condition without air source. Please pump the tank with vacuum air before

use.

Tips:

1.

Benefits for gradually and slowly turn on air inlet valve is for reducing air-consumption and a quicker

speed for vacuum-generation.

2.

Benefits for vacuum generation of both cylinder and oil tank is fasting the speed of oil transferring.

3.

We suggest extract both cylinder and tank to be vacuum when the machine is needed to be used to the

place without air compressor. That will benefit long time continuously working.

4)

Extraction

1.

Choose suitable probe (which is the largest diameter one can be inserted into the engine) and tightly

connect it to the extraction pipe connector. (refer to Fig.01)

Содержание JA1041OD

Страница 1: ...1 Pneumatic Oil Extractor Operational Manual Model No JA1041OD ...

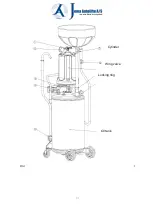

Страница 12: ...12 FIG 3 2 Cylinder Locking ring Wing valve Oil tank ...

Страница 13: ...13 ...

Страница 15: ...15 ...