alent meeting standards SAE J1703 and DOT 3. Do

not use any other type of fluid.

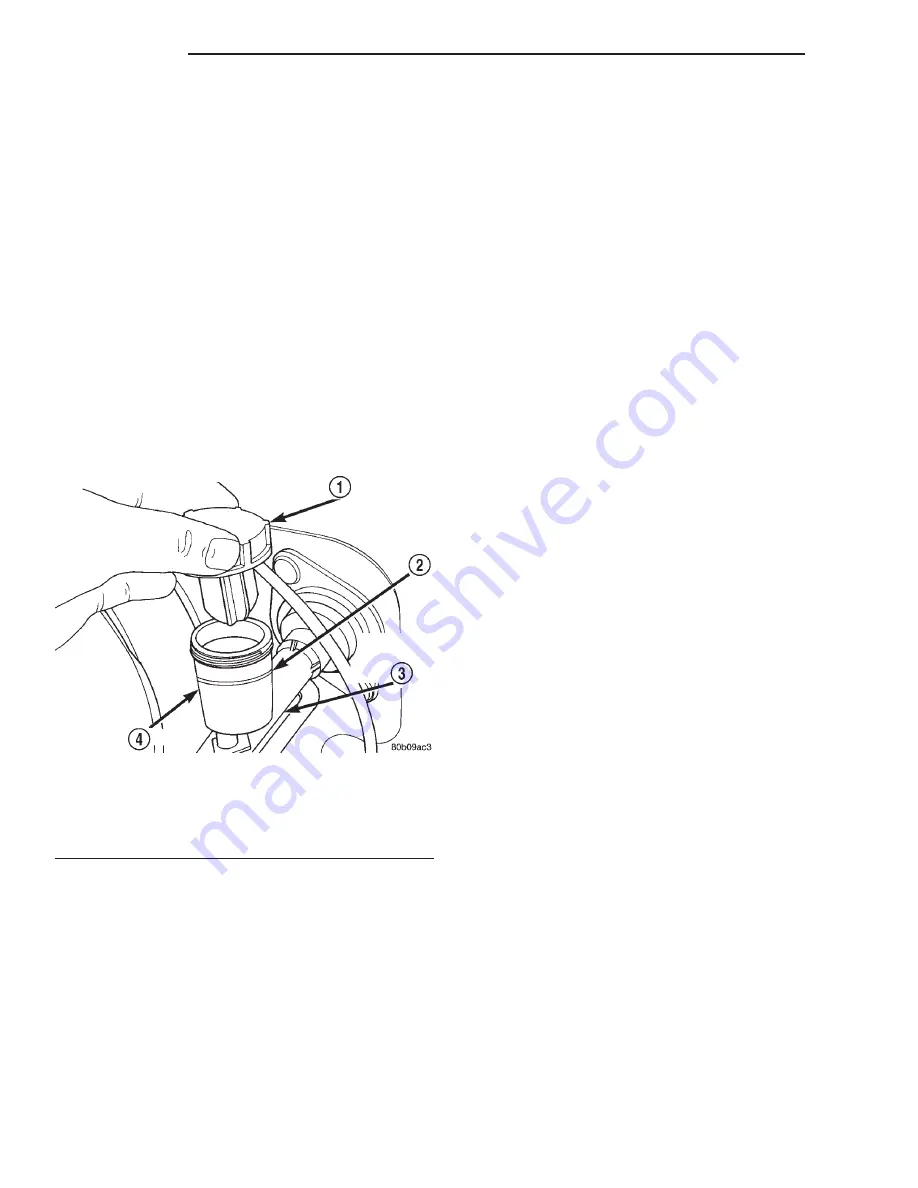

CLUTCH FLUID LEVEL

The clutch fluid reservoir, master cylinder, slave

cylinder and fluid lines are pre-filled with fluid at

the factory during assembly operations.

The hydraulic system should not require additional

fluid under normal circumstances. In fact, the reser-

voir fluid level will actually increase as normal

clutch wear occurs. For this reason, it is impor-

tant to avoid overfilling, or removing fluid from

the reservoir.

Clutch fluid level is checked at the master cylinder

reservoir (Fig. 9). An indicator ring is provided on the

outside rim of the reservoir.

Be sure to wipe the reservoir and cover clean

before removing the cover. This will avoid having dirt

or foreign material fall into the reservoir during a

fluid level check.

FLYWHEEL

Inspect the flywheel whenever the clutch disc,

cover and housing are removed for service. Check

condition of the flywheel face, hub, ring gear teeth,

and flywheel bolts.

Minor scratches, burrs, or glazing on the flywheel

face can be reduced with 180 grit emery cloth. How-

ever, the flywheel should be replaced if the disc con-

tact surface is severely scored, heat checked, cracked,

or obviously worn.

Flywheel machining is not recommended. The fly-

wheel surface is manufactured with a unique contour

that would be negated by machining. However,

cleanup of minor flywheel scoring can be performed

by hand with 180 grit emery, or with surface grind-

ing equipment. Replace the flywheel if scoring is

deeper than 0.0762 mm (0.003 in.).

Heavy stock removal by grinding is not recom-

mended. Excessive stock removal can result in fly-

wheel cracking or warpage after installation. It can

also weaken the flywheel and interfere with proper

clutch release.

Check flywheel runout if misalignment is sus-

pected. Runout should not exceed 0.08 mm (0.003

in.). Measure runout at the outer edge of the fly-

wheel face with a dial indicator. Mount the dial indi-

cator on a stud installed in place of one of the clutch

housing attaching bolts.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout.

Check condition of the flywheel hub and attaching

bolts. Replace the flywheel if the hub exhibits cracks

in the area of the attaching bolt holes.

Install new attaching bolts whenever the flywheel

is replaced and use Mopar

t

Lock N’ Seal, or Loctite

242 on the replacement bolt threads.

Recommended flywheel bolt torques are:

•

142 N·m (105 ft. lbs.) for 6-cylinder flywheels

•

95 N·m (70 ft. lbs.) for 4-cylinder flywheels

Inspect the teeth on the starter ring gear. If the

teeth are worn or damaged, the flywheel should

be replaced as an assembly. This is the recom-

mended and preferred method of repair.

In cases where a new flywheel is not readily avail-

able, a replacement ring gear can be installed. How-

ever, the following precautions must be observed to

avoid damaging the flywheel and replacement gear.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Wear protective goggles or approved safety

glasses. Also wear heat resistent gloves when han-

dling a heated ring gear.

(3) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

(4) The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating in

order to install it. The method of heating and

expanding the gear is extremely important.

Every surface of the gear must be heated at the same

time to produce uniform expansion. An oven or simi-

lar enclosed heating device must be used. Tempera-

ture required for uniform expansion is approximately

375° F.

Fig. 9 Clutch Master Cylinder Reservoir And Cap

1 – CAP

2 – FILL LINE

3 – CLUTCH MASTER CYLINDER

4 – RESERVOIR

6 - 10

CLUTCH

XJ

SERVICE PROCEDURES (Continued)

Содержание Cherokee 2000

Страница 4: ......

Страница 36: ......

Страница 96: ...Fig 105 Gear Tooth Contact Patterns 3 60 TUBE 181 AND 186 FBI AXLE XJ ADJUSTMENTS Continued...

Страница 100: ...Installer D 144 Installer W 262 3 64 TUBE 181 AND 186 FBI AXLE XJ SPECIAL TOOLS Continued...

Страница 134: ...Fig 79 Gear Tooth Contact Patterns 3 98 194 RBI AXLE XJ ADJUSTMENTS Continued...

Страница 166: ...Fig 59 Gear Tooth Contact Patterns 3 130 8 1 4 REAR AXLE XJ ADJUSTMENTS Continued...

Страница 215: ...Fig 8 Clutch Components And Inspection XJ CLUTCH 6 5 DIAGNOSIS AND TESTING Continued...

Страница 226: ......

Страница 231: ...Fig 8 Clutch Components And Inspection XJ CLUTCH 6 5 DIAGNOSIS AND TESTING Continued...

Страница 242: ......

Страница 284: ......

Страница 290: ...Wiring Diagram Symbols 8W 01 6 8W 01 GENERAL INFORMATION XJ DESCRIPTION AND OPERATION Continued...

Страница 300: ......

Страница 372: ......

Страница 376: ......

Страница 382: ......

Страница 404: ......

Страница 412: ......

Страница 416: ......

Страница 430: ......

Страница 444: ......

Страница 448: ......

Страница 468: ......

Страница 482: ......

Страница 500: ......

Страница 508: ......

Страница 520: ......

Страница 526: ......

Страница 532: ......

Страница 540: ......

Страница 550: ......

Страница 633: ...Fig 1 Front End Lighting XJ 8W 90 CONNECTOR LOCATIONS 8W 90 9 DESCRIPTION AND OPERATION Continued...

Страница 634: ...Fig 2 Left Engine Compartment 2 5L Engine LHD 8W 90 10 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 635: ...Fig 3 Left Engine Compartment 2 5L Engine RHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 11 DESCRIPTION AND OPERATION Continued...

Страница 639: ...Fig 8 Engine Compartment Components LHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 15 DESCRIPTION AND OPERATION Continued...

Страница 640: ...Fig 9 Engine Compartment Components RHD 8W 90 16 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 641: ...Fig 10 Left Engine Compartment 4 0L Engine LHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 17 DESCRIPTION AND OPERATION Continued...

Страница 642: ...Fig 11 Left Engine Compartment 4 0L Engine RHD 8W 90 18 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 647: ...Fig 16 2 5L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 23 DESCRIPTION AND OPERATION Continued...

Страница 648: ...Fig 17 4 0L Engine 8W 90 24 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 649: ...Fig 18 4 0L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 25 DESCRIPTION AND OPERATION Continued...

Страница 650: ...Fig 19 Transmission Connectors 2 5L Engine 8W 90 26 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 651: ...Fig 20 Transmission Connectors 4 0L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 27 DESCRIPTION AND OPERATION Continued...

Страница 652: ...Fig 21 Instrument Panel LHD 8W 90 28 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 653: ...Fig 22 Instrument Panel LHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 29 DESCRIPTION AND OPERATION Continued...

Страница 654: ...Fig 23 Instrument Panel RHD 8W 90 30 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 655: ...Fig 24 Instrument Panel RHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 31 DESCRIPTION AND OPERATION Continued...

Страница 656: ...Fig 25 Under Dash Components 8W 90 32 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 657: ...Fig 26 Left Side Body LHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 33 DESCRIPTION AND OPERATION Continued...

Страница 658: ...Fig 27 Left Side Body RHD 8W 90 34 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 659: ...Fig 28 Left Rear Body XJ 8W 90 CONNECTOR LOCATIONS 8W 90 35 DESCRIPTION AND OPERATION Continued...

Страница 660: ...Fig 29 Right Side Body and Junction Block 8W 90 36 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 662: ...Fig 31 Liftgate 8W 90 38 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 663: ...Fig 32 Center Console LHD XJ 8W 90 CONNECTOR LOCATIONS 8W 90 39 DESCRIPTION AND OPERATION Continued...

Страница 664: ...Fig 33 Trailer Tow Fig 34 Headliner 8W 90 40 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 665: ...Fig 35 Steering Column XJ 8W 90 CONNECTOR LOCATIONS 8W 90 41 DESCRIPTION AND OPERATION Continued...

Страница 666: ......

Страница 679: ...Fig 9 Front End Lighting Splices XJ 8W 95 SPLICE LOCATIONS 8W 95 13 DESCRIPTION AND OPERATION Continued...

Страница 680: ...Fig 10 Engine Wiring Splices 4 0L Engine 8W 95 14 8W 95 SPLICE LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 681: ...Fig 11 Engine Wiring Splices 2 5L Engine XJ 8W 95 SPLICE LOCATIONS 8W 95 15 DESCRIPTION AND OPERATION Continued...

Страница 682: ...Fig 12 Instrument Panel Wiring Splices LHD 8W 95 16 8W 95 SPLICE LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 683: ...Fig 13 Instrument Panel Wiring Splices RHD XJ 8W 95 SPLICE LOCATIONS 8W 95 17 DESCRIPTION AND OPERATION Continued...

Страница 684: ...Fig 14 Instrument Panel to Body Harness Splices 8W 95 18 8W 95 SPLICE LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 685: ...Fig 15 Left Side Body Harness Splices XJ 8W 95 SPLICE LOCATIONS 8W 95 19 DESCRIPTION AND OPERATION Continued...

Страница 686: ...Fig 16 Right Side Body Harness Splices 8W 95 20 8W 95 SPLICE LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 690: ...Fig 23 Headliner Splices 8W 95 24 8W 95 SPLICE LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Страница 810: ......

Страница 826: ...Fig 6 Frame Dimensions 13 8 FRAME AND BUMPERS XJ SPECIFICATIONS Continued...

Страница 828: ......

Страница 949: ...6747 1A Adapter Fixture MD 998805 Installer Seal XJ AX5 MANUAL TRANSMISSION 21 41 SPECIAL TOOLS Continued...

Страница 998: ...Fig 1 30RH Automatic Transmission 21 90 AUTOMATIC TRANSMISSION 30RH XJ DESCRIPTION AND OPERATION Continued...

Страница 1023: ...Fig 33 Switch Valve Torque Converter Unlocked XJ AUTOMATIC TRANSMISSION 30RH 21 115 DESCRIPTION AND OPERATION Continued...

Страница 1024: ...Fig 34 Switch Valve Torque Converter Locked 21 116 AUTOMATIC TRANSMISSION 30RH XJ DESCRIPTION AND OPERATION Continued...

Страница 1110: ...HYDRAULIC FLOW IN PARK NEUTRAL 21 202 AUTOMATIC TRANSMISSION 30RH XJ SCHEMATICS AND DIAGRAMS Continued...

Страница 1111: ...HYDRAULIC FLOW IN D FIRST GEAR XJ AUTOMATIC TRANSMISSION 30RH 21 203 SCHEMATICS AND DIAGRAMS Continued...

Страница 1112: ...HYDRAULIC FLOW IN D SECOND GEAR 21 204 AUTOMATIC TRANSMISSION 30RH XJ SCHEMATICS AND DIAGRAMS Continued...

Страница 1113: ...HYDRAULIC FLOW IN D THIRD GEAR XJ AUTOMATIC TRANSMISSION 30RH 21 205 SCHEMATICS AND DIAGRAMS Continued...

Страница 1114: ...HYDRAULIC FLOW IN D THIRD GEAR CONVERTER CLUTCH APPLIED 21 206 AUTOMATIC TRANSMISSION 30RH XJ SCHEMATICS AND DIAGRAMS Continued...

Страница 1115: ...HYDRAULIC FLOW AT PART THROTTLE 3 2 KICKDOWN XJ AUTOMATIC TRANSMISSION 30RH 21 207 SCHEMATICS AND DIAGRAMS Continued...

Страница 1116: ...HYDRAULIC FLOW AT FULL THROTTLE 3 2 KICKDOWN 21 208 AUTOMATIC TRANSMISSION 30RH XJ SCHEMATICS AND DIAGRAMS Continued...

Страница 1117: ...HYDRAULIC FLOW IN MANUAL SECOND XJ AUTOMATIC TRANSMISSION 30RH 21 209 SCHEMATICS AND DIAGRAMS Continued...

Страница 1118: ...HYDRAULIC FLOW IN MANUAL LOW 21 210 AUTOMATIC TRANSMISSION 30RH XJ SCHEMATICS AND DIAGRAMS Continued...

Страница 1119: ...HYDRAULIC FLOW IN REVERSE XJ AUTOMATIC TRANSMISSION 30RH 21 211 SCHEMATICS AND DIAGRAMS Continued...

Страница 1243: ...Fig 299 Upper Body Components XJ AW 4 AUTOMATIC TRANSMISSION 21 335 DISASSEMBLY AND ASSEMBLY Continued...

Страница 1247: ...AW 4 BUSHING AND PISTON CLEARANCE XJ AW 4 AUTOMATIC TRANSMISSION 21 339 SPECIFICATIONS Continued...

Страница 1248: ...AW 4 RETAINER AND PISTON SPECIFICATIONS 21 340 AW 4 AUTOMATIC TRANSMISSION XJ SPECIFICATIONS Continued...

Страница 1250: ...AW 4 VALVE AND SPRING IDENTIFICATION 21 342 AW 4 AUTOMATIC TRANSMISSION XJ SPECIFICATIONS Continued...

Страница 1316: ......

Страница 1327: ...SPECIFICATIONS TORQUE CHART DESCRIPTION TORQUE Lug Nut 1 2 X 20 with 60 Cone 115 150 N m 85 115 ft lbs XJ TIRES AND WHEELS 22 11...

Страница 1328: ......

Страница 1353: ...Fig 3 Hood Components XJ BODY 23 25 REMOVAL AND INSTALLATION Continued...

Страница 1396: ...WELD LOCATIONS UPPER COWL 23 68 BODY XJ SPECIFICATIONS Continued...

Страница 1397: ...UPPER COWL XJ BODY 23 69 SPECIFICATIONS Continued...

Страница 1398: ...COWL 23 70 BODY XJ SPECIFICATIONS Continued...

Страница 1399: ...A PILLAR XJ BODY 23 71 SPECIFICATIONS Continued...

Страница 1400: ...A PILLAR 23 72 BODY XJ SPECIFICATIONS Continued...

Страница 1401: ...A PILLAR XJ BODY 23 73 SPECIFICATIONS Continued...

Страница 1402: ...A PILLAR 23 74 BODY XJ SPECIFICATIONS Continued...

Страница 1403: ...B PILLAR XJ BODY 23 75 SPECIFICATIONS Continued...

Страница 1404: ...D PILLAR 23 76 BODY XJ SPECIFICATIONS Continued...

Страница 1405: ...FUEL FILLER OPENING XJ BODY 23 77 SPECIFICATIONS Continued...

Страница 1406: ...CARGO AREA FLOOR PAN 23 78 BODY XJ SPECIFICATIONS Continued...

Страница 1407: ...ROOF AND D PILLAR XJ BODY 23 79 SPECIFICATIONS Continued...

Страница 1408: ...LIFTGATE OPENING 23 80 BODY XJ SPECIFICATIONS Continued...

Страница 1409: ...ROOF XJ BODY 23 81 SPECIFICATIONS Continued...

Страница 1410: ...ROOF 23 82 BODY XJ SPECIFICATIONS Continued...

Страница 1411: ...FRAME RAIL XJ BODY 23 83 SPECIFICATIONS Continued...

Страница 1412: ...FRAME RAIL 23 84 BODY XJ SPECIFICATIONS Continued...

Страница 1413: ...FRAME RAIL XJ BODY 23 85 SPECIFICATIONS Continued...

Страница 1414: ...FRAME RAIL 23 86 BODY XJ SPECIFICATIONS Continued...

Страница 1415: ...REINFORCEMENT XJ BODY 23 87 SPECIFICATIONS Continued...

Страница 1416: ...FRONT INNER FENDER 23 88 BODY XJ SPECIFICATIONS Continued...

Страница 1417: ...FRONT INNER FENDER AND RADIATOR CLOSURE PANEL XJ BODY 23 89 SPECIFICATIONS Continued...

Страница 1418: ...REINFORCEMENT 23 90 BODY XJ SPECIFICATIONS Continued...

Страница 1419: ...FRONT FENDER XJ BODY 23 91 SPECIFICATIONS Continued...

Страница 1420: ...BODY SIDE 23 92 BODY XJ SPECIFICATIONS Continued...

Страница 1421: ...REAR WHEELHOUSE XJ BODY 23 93 SPECIFICATIONS Continued...

Страница 1422: ...REAR INNER WHEELHOUSE 23 94 BODY XJ SPECIFICATIONS Continued...

Страница 1423: ...BODY SIDE XJ BODY 23 95 SPECIFICATIONS Continued...

Страница 1424: ...BODY SIDE 23 96 BODY XJ SPECIFICATIONS Continued...

Страница 1425: ...BODY SIDE XJ BODY 23 97 SPECIFICATIONS Continued...

Страница 1426: ...BODY SIDE 23 98 BODY XJ SPECIFICATIONS Continued...

Страница 1427: ...BODY SIDE XJ BODY 23 99 SPECIFICATIONS Continued...

Страница 1428: ...BODY SIDE 23 100 BODY XJ SPECIFICATIONS Continued...

Страница 1429: ...UNDERBODY XJ BODY 23 101 SPECIFICATIONS Continued...

Страница 1430: ...UNDERBODY 23 102 BODY XJ SPECIFICATIONS Continued...

Страница 1431: ...UNDERBODY XJ BODY 23 103 SPECIFICATIONS Continued...

Страница 1432: ...UNDERBODY 23 104 BODY XJ SPECIFICATIONS Continued...

Страница 1433: ...UNDERBODY XJ BODY 23 105 SPECIFICATIONS Continued...

Страница 1434: ...UNDERBODY 23 106 BODY XJ SPECIFICATIONS Continued...

Страница 1435: ...UNDERBODY XJ BODY 23 107 SPECIFICATIONS Continued...

Страница 1436: ...UNDERBODY 23 108 BODY XJ SPECIFICATIONS Continued...

Страница 1437: ...UNDERBODY XJ BODY 23 109 SPECIFICATIONS Continued...

Страница 1438: ...UNDERBODY 23 110 BODY XJ SPECIFICATIONS Continued...

Страница 1439: ...UNDERBODY XJ BODY 23 111 SPECIFICATIONS Continued...

Страница 1440: ...BODY SEALING LOCATIONS APPLICATION METHODS 23 112 BODY XJ SPECIFICATIONS Continued...

Страница 1441: ...COWL AND DASH PANEL XJ BODY 23 113 SPECIFICATIONS Continued...

Страница 1442: ...DASH PANEL AND FLOOR PAN 23 114 BODY XJ SPECIFICATIONS Continued...

Страница 1443: ...FLOOR PAN XJ BODY 23 115 SPECIFICATIONS Continued...

Страница 1444: ...REAR INNER WHEELHOUSE 23 116 BODY XJ SPECIFICATIONS Continued...

Страница 1445: ...FRONT INNER WHEELHOUSE XJ BODY 23 117 SPECIFICATIONS Continued...

Страница 1446: ...BODY SIDE 23 118 BODY XJ SPECIFICATIONS Continued...

Страница 1447: ...BODY SIDE XJ BODY 23 119 SPECIFICATIONS Continued...

Страница 1448: ...BODY SIDE 23 120 BODY XJ SPECIFICATIONS Continued...

Страница 1449: ...ROOF PANEL XJ BODY 23 121 SPECIFICATIONS Continued...

Страница 1450: ...FUEL FILLER HOUSING 23 122 BODY XJ SPECIFICATIONS Continued...

Страница 1451: ...LIFTGATE OPENING XJ BODY 23 123 SPECIFICATIONS Continued...

Страница 1452: ...STRUCTURAL ADHESIVE LOCATIONS LEFT QUARTER PANEL 23 124 BODY XJ SPECIFICATIONS Continued...

Страница 1453: ...REAR WHEELHOUSE XJ BODY 23 125 SPECIFICATIONS Continued...

Страница 1454: ...ROOF BOWS 23 126 BODY XJ SPECIFICATIONS Continued...

Страница 1464: ......

Страница 1512: ......

Страница 1528: ......