18

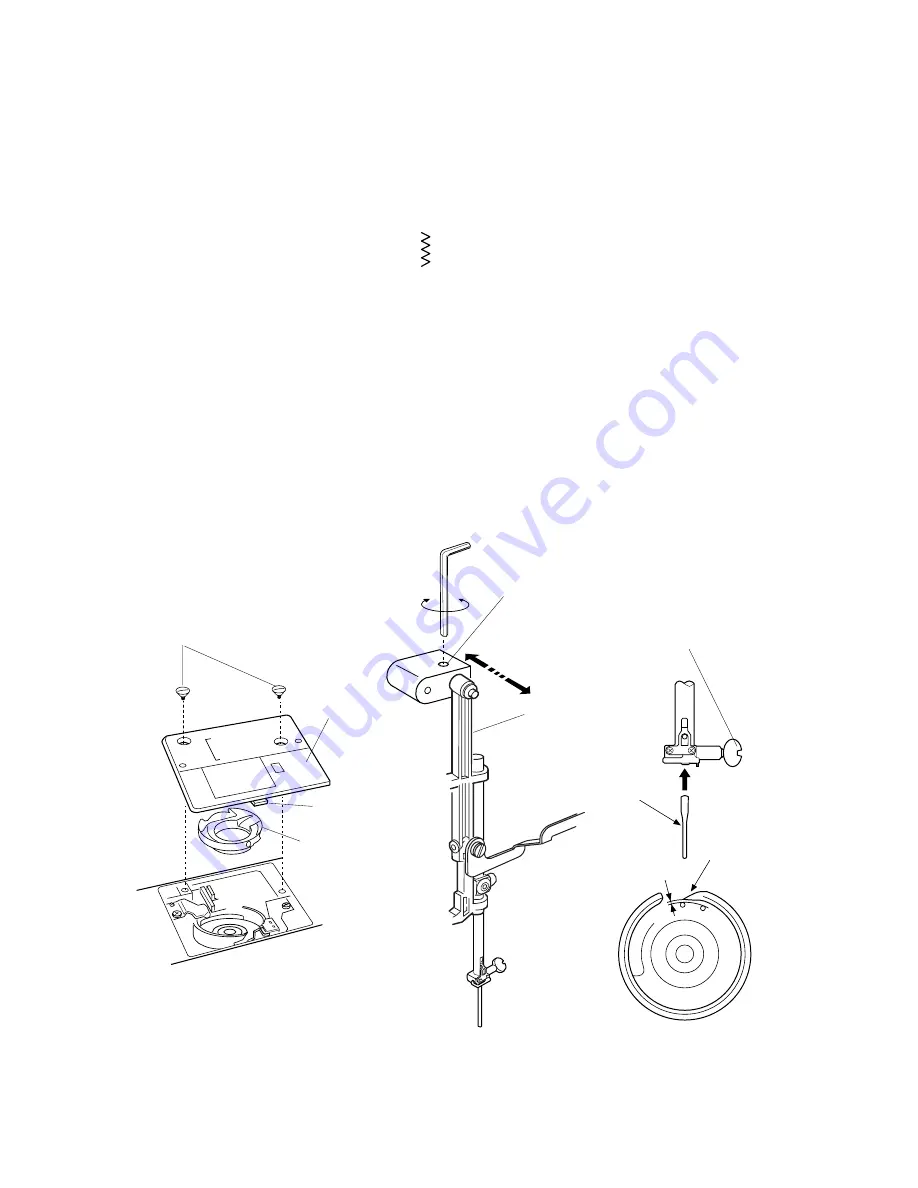

THE CLEARANCE BETWEEN THE TEST PIN AND THE TIP OF THE SHUTTLE HOOK SHOULD BE BETWEEN

-0.10 MM TO +0.05 MM.

TO CHECK:

1. SET THE PATTERN SELECTOR DIAL AT “ “, ZIGZAG WIDTH DIAL AT “ 0 “.

2. REMOVE THE NEEDLE PLATE (A), AND BOBBIN HOLDER (B).

3. ATTACH THE TEST PIN (D) AND PUSH IT UP UNTIL IT STOPS AND THEN TIGHTEN THE NEEDLE CLAMP

SCREW (E).

4. REMOVE THE FACE COVER (SEE PAGE 6).

5. TURN THE HANDWHEEL TOWARD YOU SLOWLY BY HAND UNTIL TIP OF THE TEST PIN MEETS JUST

IN FRONT OF THE TIP OF THE SHUTTLE HOOK, LOOSEN THE SETSCREW (C) AND MOVE THE NEEDLE

BAR SUPPORTER BACK OR FORTH AS SHOWN BY THE ARROW TO ADJUST THE CLEARANCE WITHIN

A RANGE OF -0.10 TO +0.05 MM.

6. TIGHTEN THE SETSCREW (C).

7. SET THE ZIGZAG WIDTH DIAL AT “5”, TURN THE HANDWHEEL TOWARD YOU TO CHECK THE NEEDLE

CLEARANCE AT BOTH LEFT AND RIGHT NEEDLE DROP POSITION.

8. ATTACH THE FACE COVER.

9. ATTACH THE BOBBIN HOLDER (B), NEEDLE PLATE (A) AND NEEDLE.

MECHANICAL ADJUSTMENT

NEEDLE CLEARANCE TO SHUTTLE

NEEDLE PLATE

SETSCREWS

N E E D L E

PLATE (A)

BOBBIN HOLDER (B)

SETSCREW (C)

N E E D L E B A R

SUPPORTER (F)

TEST PIN (D)

NEEDLE CLAMP SCREW (E)

-0.10 TO +0.05 MM

SHARP END OF

SHUTTLE HOOK

HOOK

Содержание 4052lx

Страница 1: ...SERVICE MANUAL 4052LX...

Страница 29: ...27 WIRING OF TERMINAL BLOCK RIDGE RIDGE FROM MOTOR FROM LAMP SOCKET...