Page 6

ENGLISH

Jandy

®

Pro Series VS PlusHP Pumps

|

Installation & Operation Manual

Section 2. General Description

2.1 Introduction

This manual contains information for the proper

installation, operation, and maintenance of Jandy Pro

Series VS Plus HP pumps. Procedures in this manual

must be followed exactly. To obtain additional copies

of this manual, contact Zodiac Pool Systems LLC at

1.800.822.7933 or visit www.zodiacpoolsystems.com.

2.2 Description

The VS Plus HP is a variable-speed pump that can

run from 600-3450 RPM. When connected to the

JEP-R controller, up to eight (8) speed settings may

be programmed and recalled. This allows you to select

the most appropriate speed for your application. Even

more versatile programming is possible when you use

an AquaLink® RS, AquaLink PDA, or AquaLink Z4

controller.

The pump is driven by a variable speed ECM

(Electronically Commutated Motor) directly attached

to the pump impeller which forces water flow. The rate

variability allows for optimal flow during various pump

cycles. As a result, the energy efficiency of the pump is

maximized which means cost savings to the pool owner

while also helping to save the environment.

2.3 Preparation

1. Check the carton for damage. Open the carton

and check for concealed damage, such as cracks,

dents, or a bent base. If you find damage, contact

the shipper or the distributor where the pump was

purchased.

2. Inspect the contents of the carton and verify that

all parts are included. See “Figure 1. Carton

Contents”.

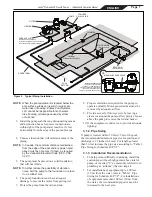

Figure 1. Carton Contents

02

01

03

04

05

06

07

09

08

15

10

11

12

13

14

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

VSPHP27 Pump

Installation and Operation Manual

Large Drawstring Bag

Universal Union Nut

Tailpiece

O-Ring

Small Drawstring Bag

User Interface Universal Control

Backplate Universal Control

DIP Switch Label

Cable Label

4 Conductor Cable

Terminal Bar 4 Pin

Manilla Envelope

Mounting Screw

1

1

1

2

2

2

1

1

1

1

1

1

1

1

6

ITEM

DESCRIPTION

QTY

For VSPHP27JEP Models only

- For a complete list of replacement parts

please see section 7.1

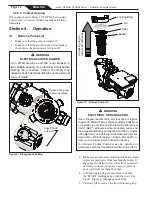

Section 3. Installation

3.1 Plumbing

3.1.1 Pump Location

WARNING

To Reduce the Risk of Fire, install pool equipment in

an area where leaves or other debris will not collect on

or around the equipment. Keep surrounding area clear

of all debris such as paper, leaves, pine-needles and

other combustible materials.

1. Zodiac Pool Systems LLC recommends installing

the pump no more than one (1) foot (30 cm) above

water level. The pump should not be installed

more than five (5) feet above the water level of

the pool. It is recommended that a check valve be

installed when pump is installed more than 3 feet

above water level.

NOTE

The pump is NSF-certified for priming at heights

up to 10 ft. above the water level. However, to

achieve better self-priming, install the pump as

close as possible to the water level of the pool.

2. If the pump is located below water level, isolation

valves must be installed on both the suction

and return lines to prevent pool water back flow

during routine or required servicing.

WARNING

A check valve can interfere with the proper operation

of certain Suction Vacuum Release System (SVRS)

products. To avoid possible entrapment hazard, seri-

ous injury, or death, make sure to review the opera-

tion/owners manual of your particular SVRS product

before installing the check valve.