Green Heating Technology

25

f

Make sure, by reading the pressure gauge

2

, that the pressure reaches the optimal value of

1 .0 bar

(max 1 .5 bar)

;

f

Turn the screw

1

on the filling electrovalve, to position

"C"

and bleed each radiator again;

f

Repeat the venting and pressurization operations until the air is completely purged from the system.

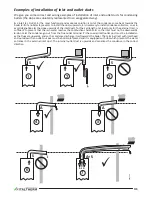

Gas connection

Due to various installation possibilities, the gas cock

3

supplied with the original Connections Kit has a

simple male Ø ½” connection, facing the rear of the boiler.

The gas pipe

4

, upstream the gas cock

3

, should

be supplied by the installer.

While connecting gas inlet pipe of the boiler to the pipe coming from gas network, it is MAN

-

DATORY to insert a PLAIN GASKET, whose dimensions and material must be adequate . Con-

nection is NOT suitable for hemp, teflon strip or similar materials. Because of the type of

fitting, the use of those materials does not make the suitable seal with consequent gas leaks!

This boiler is designed and prepared to be supplied with Natural Gas G20 (Methane) or Com-

mercial Propane G31**. A qualified technician can convert it to operate with one of these two

types of gas above said .

**(except model 18 K)

It must never be used with Butane gas G30

(that can be present, pure or mixed with Propane G31,

in the portable gas bottles for cookers)

therefore, if the boiler is prepared for operation with

commercial Propane G31, we recommend notifying the supplier of the fuel, for example, by

applying the sticker provided with the boiler

(or included in the G31 conversion kit),

on the gas

tank or in its immediate vicinity, so that it is visible to the employee when it is being refilled.

Using Propane gas G31, it is absolutely necessary to install a pressure reducer upstream the

boiler . Failure to do this, the gas valve of the boiler will get damaged .

The gas connection, as generally the boiler installation, must be done by qualified personnel as

prescribed by the regulation in force, because a faulty gas connection could lead to fire, explosion

and other very serious damages to persons, animals and objects. The manufacturer cannot be

held responsible for any damage arising from that situation.

f

Verify what follows:

•

cleaning of all system gas pipes in order to avoid the presence of work residuals that could com-

promise the correct boiler functioning;

•

gas line and ramp conformity with laws and rules currently in force;

• internal and external tightness of the gas system and connections;

• supply pipe must have a section greater than or equal to the boiler one;

• supply gas must correspond to the one for which the boiler has been set: otherwise, it's manda

-

tory to ask to qualified personnel to set the boiler for the correct gas type;

• an interception valve must be installed upstream the appliance.

f

Open the meter valve and purge the air that is inside the system pipes (including all the appliances).

Содержание 18 K

Страница 61: ...Green Heating Technology 61 Notes ...

Страница 62: ...Green Heating Technology 62 Notes ...

Страница 63: ...Green Heating Technology 63 Notes ...