isel Germany AG

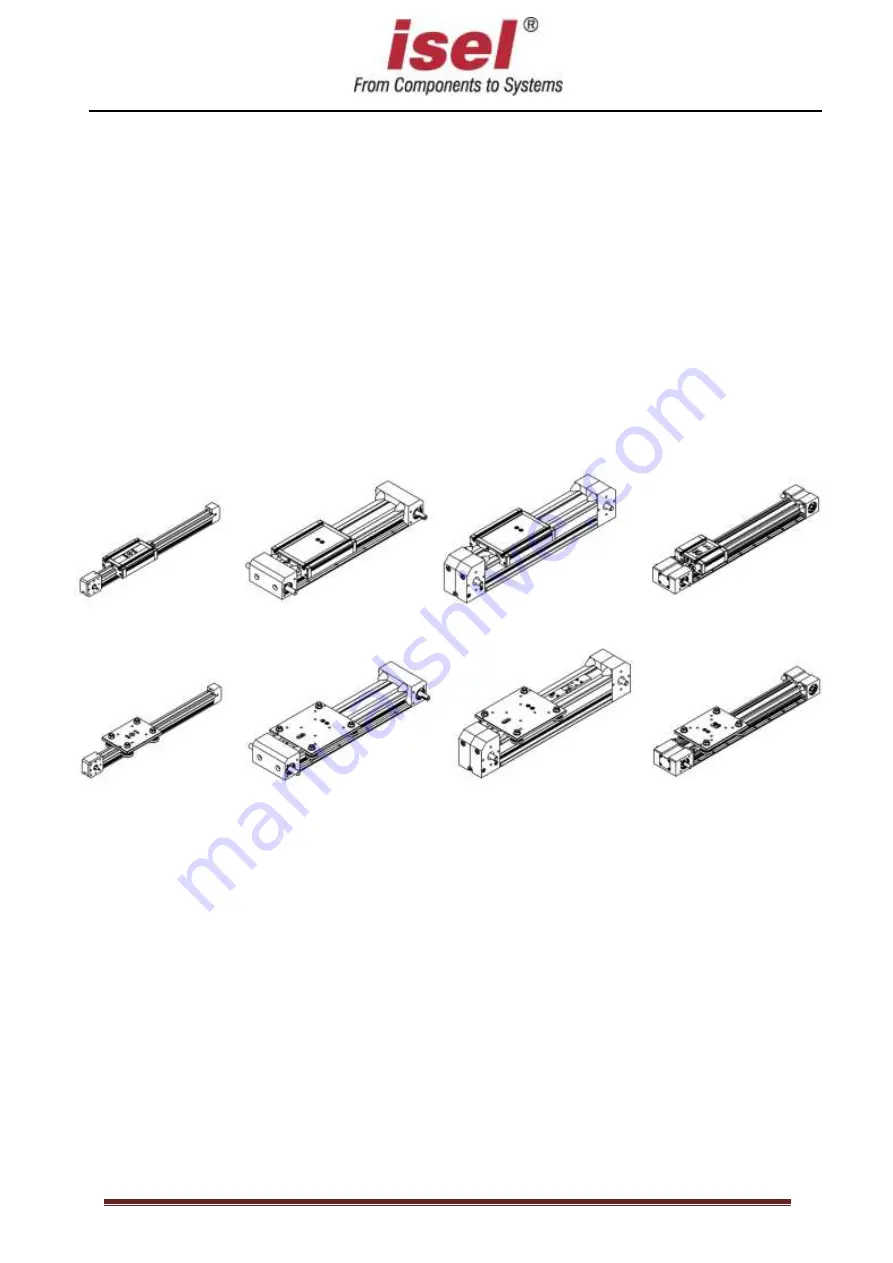

L

inear units with

t

oothed belt drive

LEZ 1

– LEZ 2 – LEZ 3 – LEZ 9

Assembly instructions with:

- Installation instructions

- Maintenance instructions

- Declaration of incorporation

for a drive system

(A partly completed machinery as defined in Machine Directive 2006/42/EG)