GRS-17000-E-01

850 SERIES

maximum allowable working pressure

(MAWP)

•

Do not allow the pump the be subjected to

temperatures greater than the maximum

allowable working temperature (MAWT)

•

If altering the pump flowrate by increasing

system resistance (e.g. by adjusting a

valve), always throttle the flow on the

discharge side of the pump. Throttling on the

suction side of the pump will decrease the

NPSHa for the pump and can cause pump

damage.

•

Do not overload the driver, which can

damage the driver and create unexpected

heat generation. A common scenario is

excessive power draw due to a change in

the system which allows the pump flowrate

to exceed the rated conditions

•

Do not operate the pump with a flowrate less

than the indicated minimum flowrate

•

Do not subject the pump to freezing

conditions. Freezing may damage the

components, leading to possible injury or

flooding.

MAINTENANCE

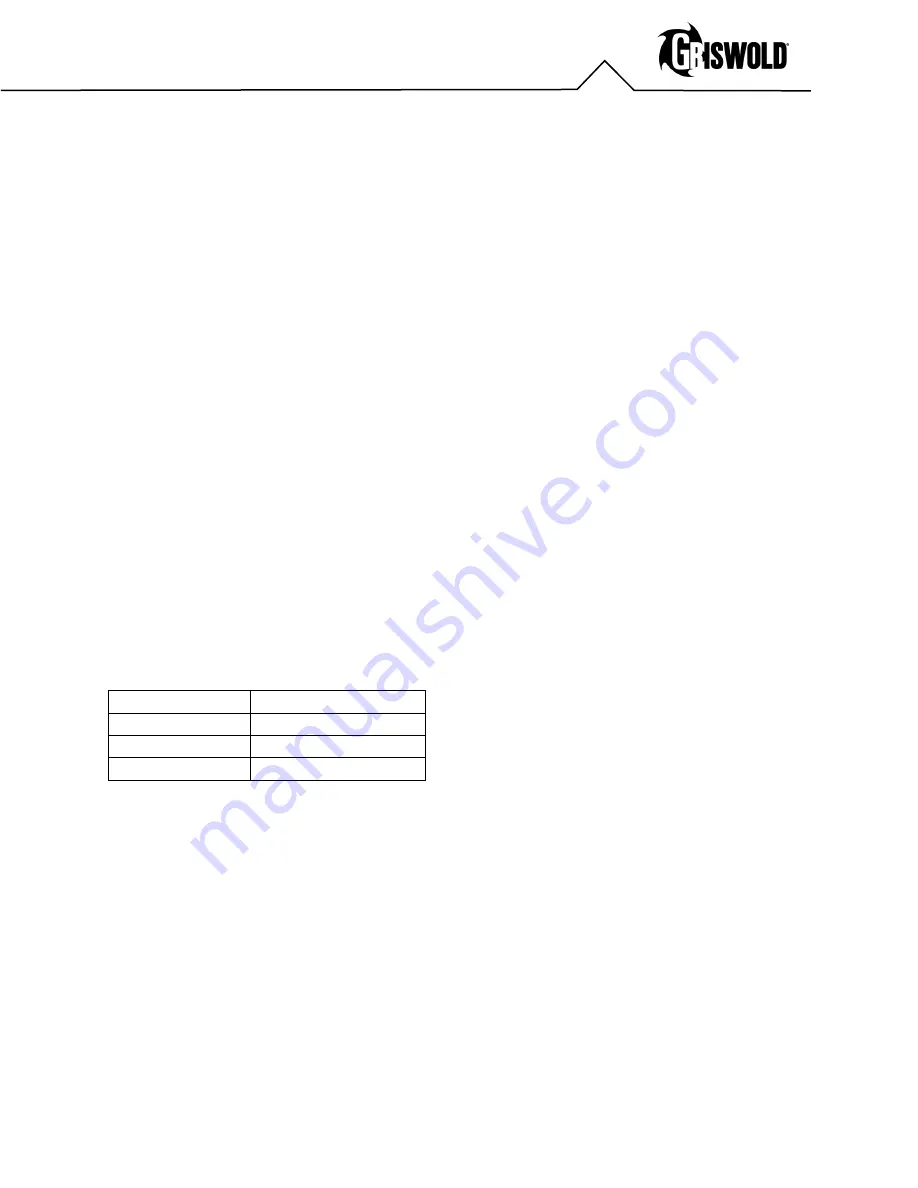

Bolt Torques

Recommended bolt torques for both hex head

and socket head cap screws

Screw Size

Recommended Torque

3/8 - 16 UNC

35 ft-lbs

1/2 - 13 UNC

85 ft-lbs

5/8

–

11 UNC

165 ft-lbs

Disassembly to Replace Mechanical Seal

•

Disconnect and lock out power to the driver

•

Close necessary valves and drain the pump

•

Flush the pump if necessary

•

Remove the case bolts and separate the

case and bracket. Since the pump is of a

back pull-out design, the pump back-end

(with the bracket) can be pulled from the

case while leaving the case bolted to the

piping. Alternatively, case can simply be

removed from the bracket and set aside

(e.g. if the pump is being disassembled on a

work bench).

•

Remove old O-ring and discard

•

Holding the impeller stationary, remove the

impeller screw and impeller washer

•

Remove the impeller

•

If present, remove the impeller spacer

•

Remove the mechanical seal spring

•

Remove the bracket. The rotating seal will

slide off during this process.

•

Push stationary seal assembly out of

bracket

Installing Mechanical Seal

•

Inspect shaft sleeve. If the outer surface is

damage, it may create a leak path under the

new rotating seal. Replace if necessary

•

If replacing sleeve, discard existing sleeve

O-ring(s). Clean shaft and apply a thin film

of assembly oil / grease. Install new sleeve

with new O-ring(s). If the sleeve has a

rectangular notch, align the notch with the

shaft keyway

•

Clean the seal bore of the bracket

•

Carefully press the new stationary seal

assembly into the bracket bore. Be careful

not to chip or damage the brittle seal face. It

is recommended to cover the seal face with

a softer material (e.g. cardboard, plastic)

during this process

•

Reinstall the bracket to the motor, taking

great care not to damage the stationary

mechanical seal face by letting it come into

contact with the motor shaft

•

Apply a thin film of assembly oil / grease to

the inner diameter of the rotating seal and

the outer diameter of the shaft sleeve and

install the rotating seal assembly onto the

sleeve, polished face first. Be sure that

enough oil / grease is present to allow the

seal to slide. Place the spring onto the back

of the rotating seal assembly and apply

pressure until the rotating mechanical seal

assembly slides to make contact with the

stationary seal face.

•

If applicable, install impeller spacer

•

Place impeller key into the shaft keyway and

slide it back

•

Apply a thin layer of assembly grease / oil to

the shaft and install impeller, pushing it back

(which will compress the mechanical seal

spring)