428 01 9702 01

3

Specifications subject to change without notice.

Operating Ambient

Minimum outdoor operating ambient in cooling mode is 55

_

F

(13

_

C), maximum 125

_

F (52

_

C).

Rigging

PERSONAL INJURY AND/OR EQUIPMENT

DAMAGE HAZARD

Failure to follow this caution may result in personal injury

and/or equipment damage.

Be sure unit panels are securely in place prior to rigging.

CAUTION

!

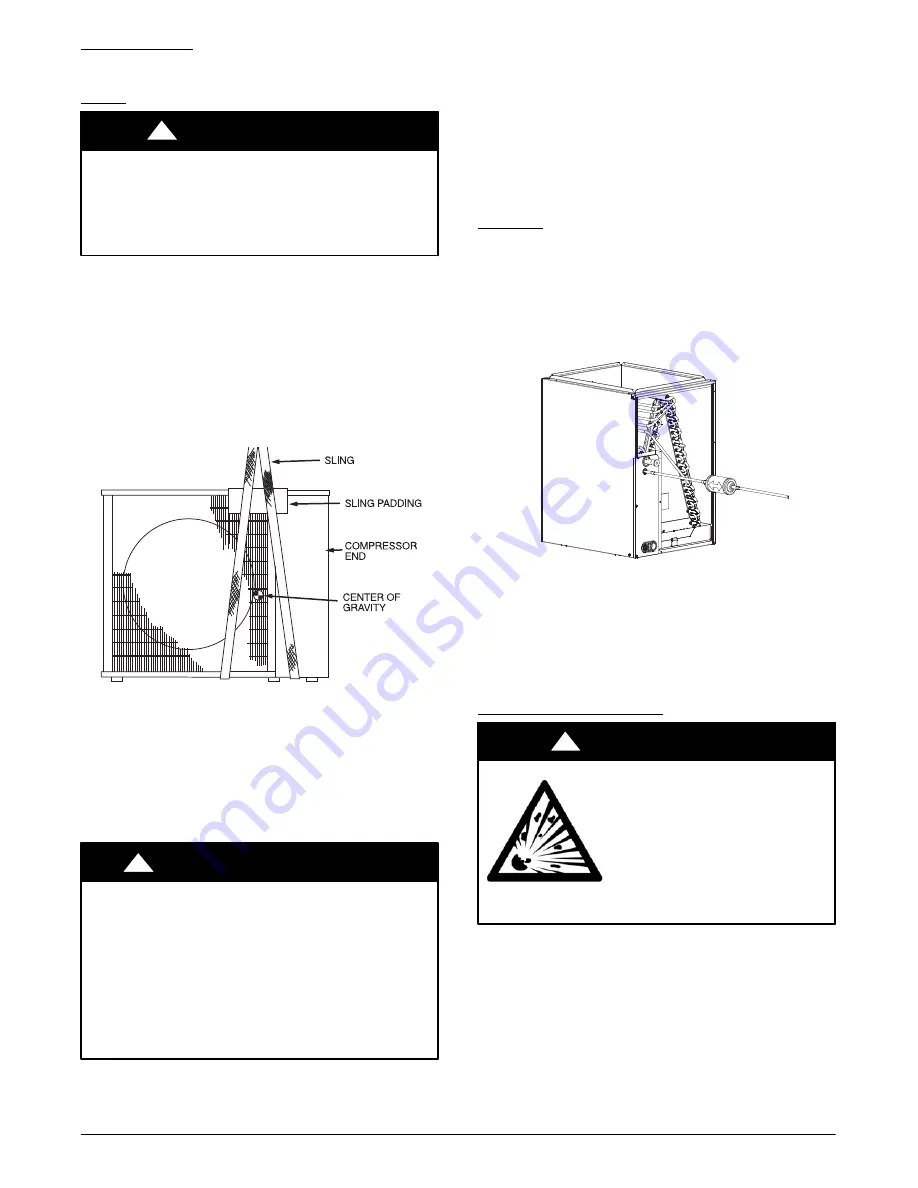

Keep the unit upright and lift unit using a sling. Use cardboard or

padding under the sling, and spreader bars to prevent sling damage

to the unit. See Fig. 3. Install the unit so that the coil does not face

into prevailing winds. If this is not possible and constant winds

above 25 mph are expected, use accessory wind baffle. See

installation instructions provided with the accessory kit.

NOTE

: Accessory wind baffles should be used on all units with

accessory low ambient temperature control.

Field

−

fabricated snow or ice stands may be used to raise unit when

operation will be required during winter months. Units may also be

wall mounted using the accessory wall mounting kit.

A07396

Fig. 3

-

Lifting Unit with Sling

COMPLETE REFRIGERANT PIPING

CONNECTIONS

Outdoor units may be connected to indoor units using

field

−

supplied tubing of refrigerant grade and condition. See

Specification Sheet for correct line sizes. Do not use less than 10 ft

(3.05 m) of interconnecting tubing.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

If any section of pipe is buried, there must be a 6 in. (152.4

mm) vertical rise to the valve connections on the outdoor

unit. If more than the recommended length is buried,

refrigerant may migrate to cooler, buried section during

extended periods of system shutdown. This causes refrigerant

slugging and could possibly damage the compressor at

start

−

up.

When more than 80 ft (24.4 m) of interconnecting tubing and more

than 20 ft (6.1 m) of vertical lift is used, consult the residential

Long Line Application Guide for required accessories. If either

refrigerant tubing or indoor coil is exposed to the atmosphere, the

system must be evacuated following good refrigeration practices.

Run refrigerant tubes as directly as possible, avoiding unnecessary

turns and bends. Suspend refrigerant tubes so they do not damage

insulation on vapor tube and do not transmit vibration to structure.

Also, when passing refrigerant tubes through a wall, seal the

opening so that vibration is not transmitted to structure. Leave

some slack in refrigerant tubes between structure and outdoor unit

to absorb vibration. Refer to separate indoor unit installation

instructions for additional information.

Filter Drier

Refer to Fig. 4 and install filter drier as follows:

1. Braze 5 in. (127 mm) liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to 5 in. (127 mm) long liquid tube from

step 1.

4. Connect and braze liquid refrigerant tube to the filter drier.

A05227

Fig. 4

-

Filter Drier Components

The filter drier must be replaced whenever the refrigeration system

is exposed to the atmosphere.

Only use factory specified liquid

−

line filter driers with rated

working pressures less than 600 psig.

NOTE

: Do not install a suction

−

line filter drier in liquid line.

Make Piping Sweat Connections

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

!

WARNING

Remove plastic caps from liquid and suction service valves. Use

refrigerant grade tubing. Service valves are closed from the factory

and are ready for brazing. After wrapping the service valve with a

wet cloth, the tubing set can be brazed to the service valve using

either silver bearing or non

−

silver bearing brazing material.

Consult local code requirements. Refrigerant tubing and the indoor

coil are now ready for leak testing.

NOTE

: Unit is shipped with R

−

410A refrigerant factory charge

indicated on nameplate.

Pass nitrogen or other inert gas through piping while brazing to

prevent formation of copper oxide.