INSTALLATION INSTRUCTIONS

Gas Furnace: (F/G)9MVE

440 01 4400 03

21

Specifications subject to change without notice.

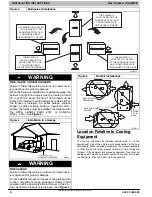

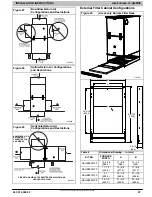

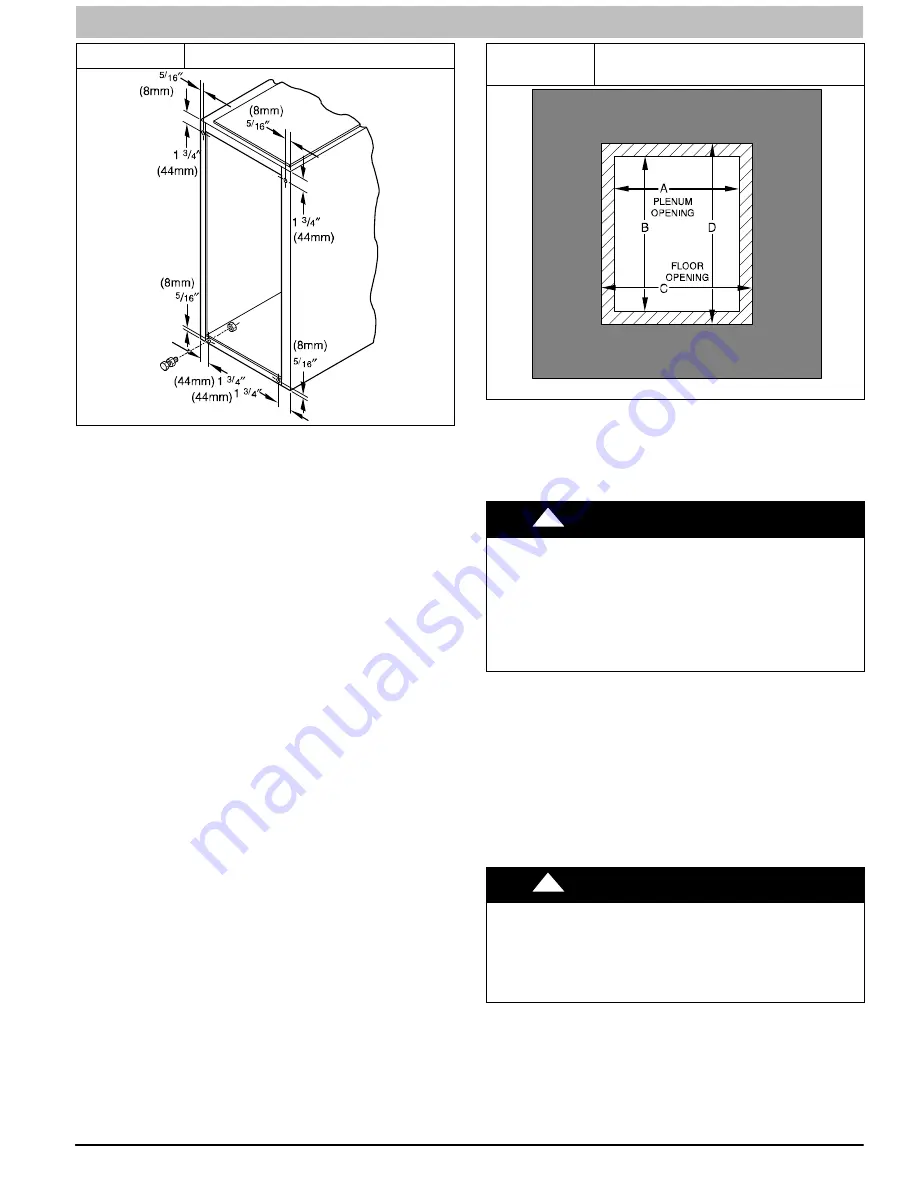

Figure 20

Leveling Legs

A89014

NOTE

: Bottom closure must be used when leveling legs are

used. It may be necessary to remove and reinstall bottom

closure panel to install leveling legs. To remove bottom closure

panel, see Step 1 in Bottom Return Air Inlet section.

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in

each bottom corner of furnace.

2. For each leg, install nut on bolt and then install bolt with

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install

flat washer if desired.)

4. Adjust outside nut to provide desired height, and tighten

inside nut to secure arrangement.

5. Reinstall bottom closure panel if removed.

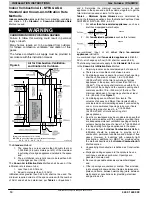

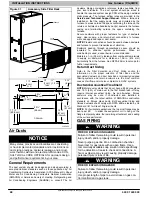

DOWNFLOW INSTALLATION

NOTE

: The furnace must be pitched as shown in

proper condensate drainage.

Supply Air Connections

NOTE

: For downflow applications, this furnace is approved for

use on combustible flooring when any one of the following two

accessories are used (see specification sheets for list of

approved accessories):

Special Base

−

NAHA01101SB

Cased Coil Assembly

−

EAM4X, END4X, ENW4X

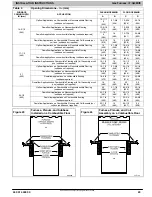

1. Determine application being installed from

.

2. Construct hole in floor per

3. Construct plenum to dimensions specified in

4. Install as shown in

used, install as shown in

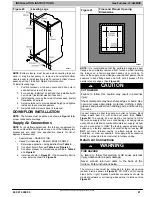

Figure 21

Floor and Plenum Opening

Dimensions

A96283

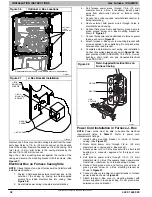

NOTE

: It is recommended that the perforated supply

−

air duct

flanges be completely removed from furnace when installing

the furnace on a factory

−

supplied cased coil or coil box. To

remove the supply

−

air duct flange, use wide duct pliers or hand

seamers to bend flange back and forth until it breaks off. Be

careful of sharp edges. (See

)

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts, and servicing

furnaces.

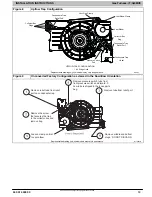

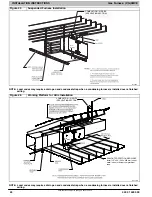

Connect supply

−

air duct to supply

−

air outlet on furnace. Bend

flange inward past 90

with wide duct pliers (See

) The supply

−

air duct must be connected to ONLY

the furnace supply outlet or air conditioning coil casing (when

used). When installed on combustible material, supply

−

air duct

must be connected to ONLY the factory

−

approved accessory

subbase, or a factory

−

approved air conditioning coil casing.

DO

NOT

cut main furnace casing to attach supply air duct,

humidifier, or other accessories. All supply

−

side accessories

MUST be connected to duct external to furnace casing.

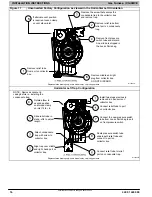

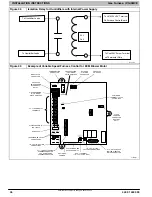

Return Air Connections

WARNING

!

FIRE HAZARD

A failure to follow this warning could cause personal

injury, death and/or property damage.

Never connect return

−

air ducts to the back of the

furnace. Follow instructions below.

The return

−

air duct must be connected to return

−

air opening

(bottom inlet) as shown in

sides (left or right). Bypass humidifier connections should be

made at ductwork or coil casing sides exterior to furnace. (See