INSTALLATION INSTRUCTIONS

R-22 Split System Air Conditioner

421 01 5001 00

7

F. SERVICE VALVES

Service valves are closed and tube stubs are plugged

from the factory. Outdoor units are shipped with a

refrigerant charge sealed in the unit. Leave the service

valves closed until all other refrigerant system work is

complete or the charge will be lost. Leave the plugs in

place until line set tubing is ready to be inserted.

Service valve bodies are brass and tube stubs are

copper.

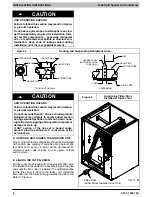

G. BRAZING CONNECTIONS

!

WARNING

FIRE HAZARD

Failure to remove refrigerant and oil charge before

brazing could result in personal injury, death, and/

or property damage.

Refrigerant and oil mixture could ignite and burn

as it escapes and contacts brazing torch. Make

sure the refrigerant charge is properly removed

from both the high and low sides of the system be‐

fore brazing any component or lines.

Clean line set tube ends with emery cloth or steel brush.

Remove any grit or debris.

Insert line set tube ends into service valve tube stubs.

Apply heat absorbing paste or heat sink product between

service valve and joint. Wrap service valves with a heat

sinking material such as a wet cloth.

Braze joints using a Sil-Fos or Phos-copper alloy.

!

CAUTION

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Braze with Sil-Fos or Phos-copper alloy on cop‐

per-to-copper joints and wrap a wet cloth around

rear of fitting to prevent damage to TXV.

H. EVACUATING LINE SET AND INDOOR COIL

The unit is shipped with a factory refrigerant charge. The

liquid line and suction line service valves have been

closed after final testing at the factory. Do not disturb

these valves until the line set and indoor coil have been

evacuated and leak checked, or the charge in the unit

may be lost.

NOTE:

Do not use any portion of the factory charge for

purging or leak testing. The factory charge is for filling the

system only after a complete evacuation and leak check

has been performed.

!

CAUTION

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Never use the outdoor unit compressor as a vacu‐

um pump. Doing so may damage the compressor.

Line set and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. If

deep vacuum equipment is not available, the alternate

triple evacuation method may be used by following the

specified procedure.

If vacuum must be interrupted during the evacuation

procedure, always break vacuum with dry nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump

capable of pulling a vacuum to 500 microns and a vacuum

gauge capable of accurately measuring this vacuum

level. The deep vacuum method is the most positive way

of assuring a system is free of air and water.

Watch the vacuum gauge as the system is pulling down.

The response of the gauge is an indicator of the condition

of the system (refer to Figure 6).

With no leaks in the system, allow the vacuum pump to

run for 30 minutes minimum at the deep vacuum level.

Figure 6

Deep Vacuum Gauge Response

and System Conditions

500

MINUTES

0

1

2

4

6

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

M

ICRONS

2500

3000

3500

4000

4500

5000

3

7

5