16575177_ed1

3

7. Using an adjustable Pin Wrench, unscrew Bearing

Cap (73).

8. Pull the Drive Spindle Assembly (69) out of Housing

Assembly (61).

9. If necessary, using a bearing puller tool, press the Rear

Spindle Bearing (72) off the Drive Spindle Assembly (69).

Then remove the Retaining Ring (71), and Washer (70).

10. Now tilt Spindle Housing, causing the Disengaging Spring

(68), Coupler (67), Square Drive Spindle (64), and

Washers (62) and (63) to slide out.

Motor Housing Disassembly

Gear Case - Disassembly

1. Carefully engage spanner holes on the Gear Case

Couping Nut (40) with the appropriate tool and loosen the

Coupling Nut while gripping the wrench flats of the Gear

Case (41) with the appropriate wrench.

2. Unthread the Coupling Nut (40) from the Motor Housing

Assembly (1) and pull the Gear Case Assembly off the

Motor Housing Assembly.

3. Remove the Pinion Coupler Assembly (34) from the

Motor Housing Assembly.

4.

For Non-Flanged Models:

If the Coupling Nut requires

replacement, slide the Coupling Nut off the Gear Case

Assembly.

5.

For Flanged Models

:

a

If the Coupling Nut requires replacement, spread the

ends of the Retaining Ring (39) and remove it from the

Gear Case Assembly.

b

Slide Coupling Nut off the Gear Case Assembly.

6. Work a pointed tool under the Ring Gear Retainer (33)

and spiral it out of the Gear Case (41).

7. Tilt the Gear Case Assembly so that the Ring Gear (37)

and 1st Stage Spindle Assembly (36) slide out of the

Gear Case Assembly.

8. With the motor end of the Gear Case Assembly standing

on the table of an Arbor press, carefully press the 2nd

Stage Spindle Assembly (38) out of the Bearing (42)

while lightly supporting the Spindle Assembly from

beneath to avoid breakage.

9. Using internal snap ring pliers, remove the Retaining

Ring (43) from the threaded end of the Gear Case (41).

10. Remove Bearing (42) from the Gear Case.

WARNING

•

This procedure is to be done by an authorized,

trained repair person. To ensure proper functioning

of the tool:

When replacing the Motor Housing Assembly (1), always

ensure that the Memory Chip (7), Communication Board (8),

Gear Case Assembly, and Attachment are all assembled as

a set with the new Motor Housing Assembly.

Grips

1. For models with levers, use the appropriate hex key to

loosen Cap Screws (23) from lever (24 or 25) and remove

lever from Handle Grip (19 or 20).

2. Use the appropriate hex key to loosen the Cap

Screw (22) from Handle Grip (18, 19, 20 or 21).

3. Slide Handle Grip off of Motor House Assembly (1).

Disassembly of External Components

1. Dislodge O-rings (15) and remove Memory Chip (7) from

assembly.

2. Remove Trigger mechanism (5) from Motor Housing

Assembly.

3. Remove Spring (6) from Trigger mechanism.

4. Slide Reverse Ring (17) away from Motor Housing

Assembly, being careful not to lose the Detent Ball (3) or

Springs (4) and (16).

5. Remove Retaining Ring (14) from behind Label Cover

Lens (13).

6. In a sliding motion, pull Warning Label (12) and Label

Cover Lens (13) off end of Motor Housing Assembly.

7. Slide Housing Cover (11) off Motor Housing Assembly.

8. Remove O-ring (10) located at front of Housing Cover.

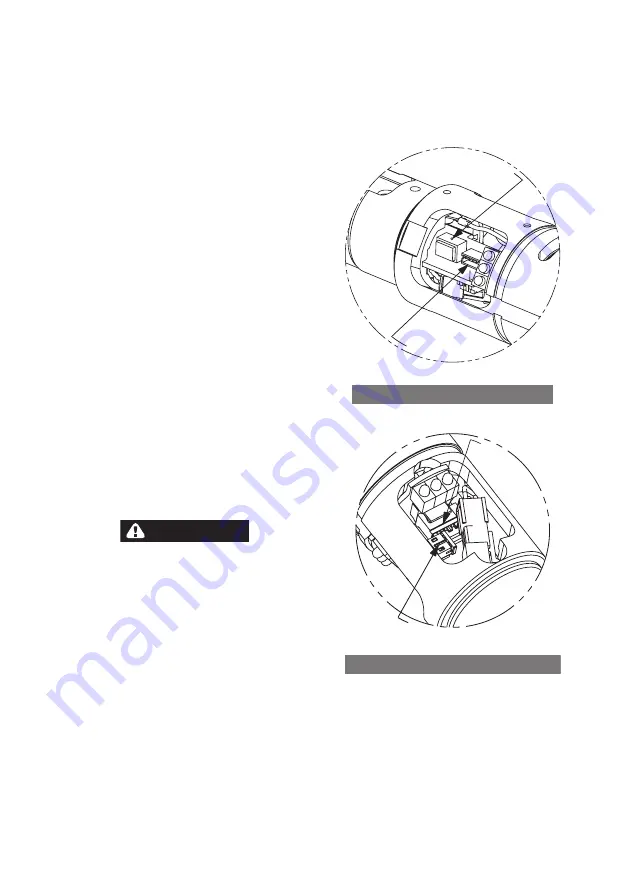

Communication Board

(Dwg. TP2162a)

(Dwg.TP2162b)

Torque and Motor Connector(s)

Torque Transducer

Motor Commutatio

n

LEDs and Temperature Connector(s)

M otor Temperatu

re

S

en

so

r

LED

Bo

ard