2

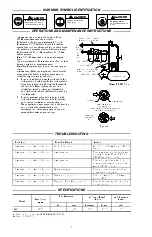

WARNING SYMBOL IDENTIFICATION

Always wear eye protection

when operating or perform-

ing maintenance on this tool.

WARNING

WARNING

Always wear hearing

protection when operating

this tool.

Read this manual before

operating tool.

WARNING

OPERATIONS AND MAINTENANCE INSTRUCTIONS

•

Always use clean, dry air at 90 psig (6.2 bar/

620 kPa) maximum at the tool inlet.

•

Lubrication -- Inject approximately 1.5 cc of

Powerforce No. 50 Oil into the air inlet before

starting the tool and after each two or three hours

of operation, unless the air line lubricator is used.

Lubricate with 1.5 cc of Powerforce No. 50 Oil

before storage.

•

Use a 3/8” (10 mm) inside diameter air supply

hose.

•

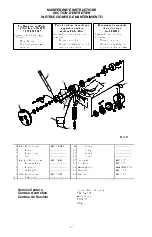

Speed Adjustment -- Rotate regulator (7) to adjust

from no rotation to maximum speed.

•

Installing/Removing sanding pad and sandpaper

discs:

Always turn off the air supply and disconnect the

air supply hose before installing, removing, or

adjusting any accessory on the tool.

1. For pad installation, have the lock tab in the

lock position (See Figure 1). For lock position,

align hole in spindle with lock tab. Press lock

tab into hole. Hand tighten the pad in a

clockwise direction. After pad installation,

unlock the lock tab for orbital action sanding

(See Figure 1).

2. For pad removal, align hole in spindle with

lock tab. Press lock tab into hole. Rotate the

pad counter clockwise to remove the pad.

3. When applying a sandpaper disc to the sanding

pad, a disc with adhesive backing is

recommended. Align sandpaper on pad and

press self adhesive paper onto pad.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905--1)

Lock tab

Install pad with tool

in LOCK position

Insert lock tab into drive cylinder hole

UNLOCK for orbital action

view from

underside of

tool

Figure 1

Drive cylinder

TROUBLESHOOTING

Problem

Possible Cause

Action

Low speed or tool will not function

Lac

k of lubrication

Add 1.5 cc of Powerforce oil #50 to

the tool

Low speed or tool will not function Low pressure

Ensure system regulators are set

properly to have 90 psi (6.2 bar/

620 kPa) at the tool inlet.

Low speed or tool will not function Low pressure

Ensure proper hose size. Long

hose lengths may require a hose

with a 1/2” ID or larger

Low speed or tool will not function System leakage

Ensure connections are tight and

hoses are not damaged

Low speed or tool will not function Debris build up in tool

Flush tool with 1.5 cc of Power-

force oil #50

Low speed or tool will not function Regulator (7) in wrong position

Ensure that the regulator is in the

proper position

SPECIFICATIONS

Model

Free Speed

rpm

Pad Diameter

H Sound Level

dB (A)

z

Vibrations

Level

Model

rpm

In

mm

Pressure

Power

m/s

2

PF100

12000

6

152

87.3

100.3

6.3

H Tested in accordance with PNEUROP PN8NTC1.2

z Tested to ISO8662