MAINTENANCE

WARNING

•

Never perform maintenance on hoist while it is supporting a load.

•

Before performing maintenance, tag controls:

•

Only allow personnel trained in operation and service of this hoist to

perform maintenance.

•

After performing any maintenance on hoist dynamically test hoist to 100%

of its rated capacity, in accordance with ASME B30.16 standards, before

returning hoist to service. Testing to more than 100% of rated capacity may

be required to comply with standards and regulations set forth in areas

outside the USA.

•

Shut off air system and depressurize air lines before performing any

maintenance.

Proper use, inspections and maintenance increase the life and usefulness of your

Ingersoll Rand equipment. During assembly, lubricate gears, nuts, capscrews and

all machined threads with applicable lubricants. Use of antiseize compound and/or

thread lubricant on capscrew and nut threaded areas prevents corrosion and allows

for easy disassembly of components.

n

Maintenance Intervals

The Maintenance Interval Chart below is based on intermittent operation of

equipment for eight hours each day, five days per week. If equipment is in operation

for more than eight hours a day or is operated in severe applications or

environments, more frequent maintenance should be performed.

Interval

Maintenance Check

Start of each shift

Make a thorough visual inspection of hoist for damage.

Do not operate hoist if damage is found.

Operate in both directions. Hoist must operate smoothly

without sticking, binding or abnormal noises.

Check operation of pendant control and brake.

Semiannually

Inspect disc brake friction linings and sprag clutch

assembly. Clean or replace parts as required.

Yearly

Inspect hoist gearing, shafts and bearings for damage or

wear. Repair or replace as necessary.

Check all of supporting members, including trolley if

used. Repair or replace as required.

n

Disc Brake Adjustment

No disc brake adjustment is required. If brake fails to hold load, brake must be

disassembled, inspected, repaired and tested prior to placing hoist in service. When

any part of friction disc thickness measures 0.072 in. (1.83 mm) or less, or if oil groove

pattern is not clearly visible, friction discs must be replaced.

n

Load Chain Replacement

n

Load Chain Weld Placement

It is suggested that a short length of 32 mm load chain be available when replacing

hoist load chain. Feeding a short length of load chain through bottom block

assembly or power head assembly prior to installing new load chain may simplify

installation.

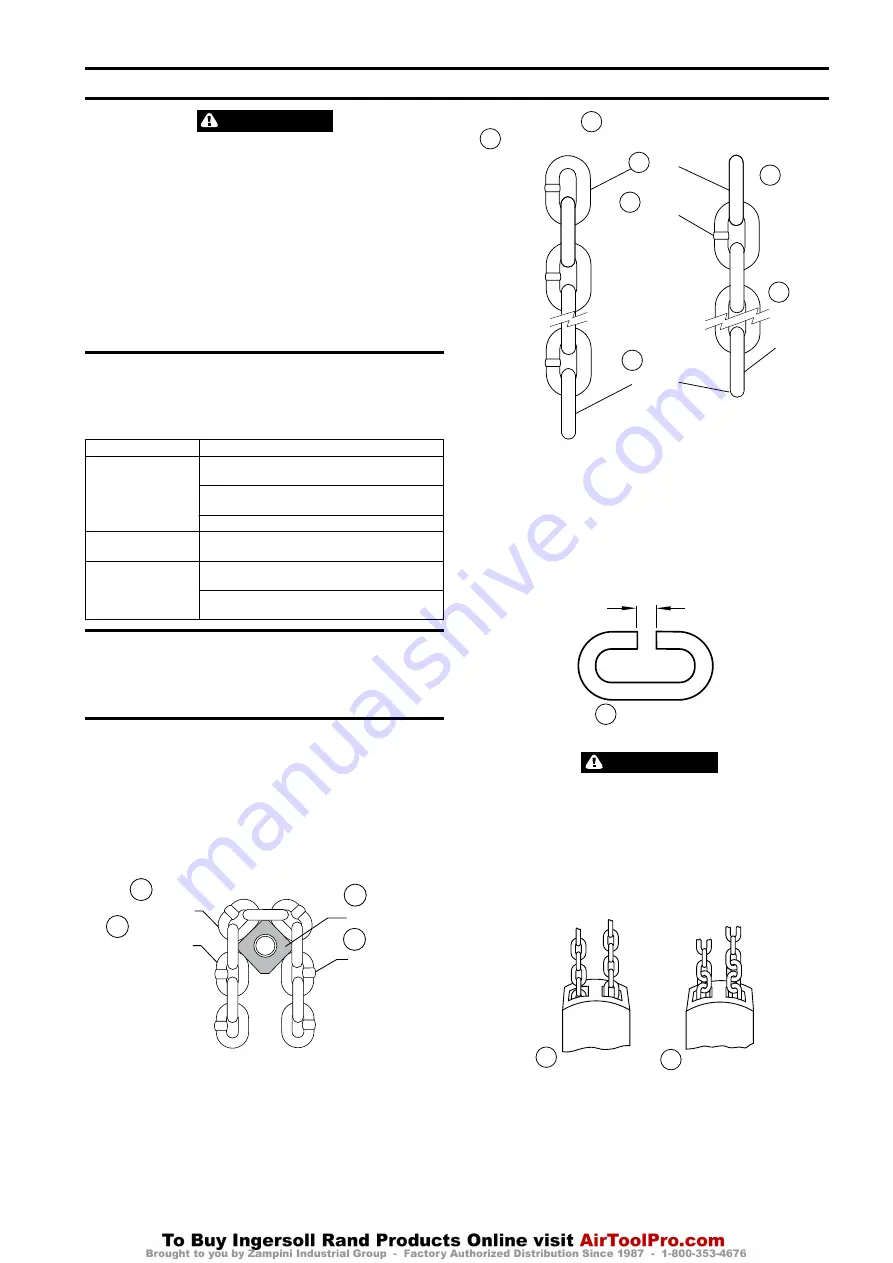

Weld on perpendicular load chain must always face away from sheaves. Refer to

Dwg. MHP0042 on page 5, A. Load Chain; B. Standing Link; C. Load Sheave; D.

Chain Weld.

Load Chain

Standing Link

Load Sheave

Chain Weld

A

B

C

D

(Dwg. MHP0042)

n

Replacement Load Chain Link Arrangement

Correct load chain installation requires that load chain have either an even or odd

number of total chain links. Refer to Dwg. MHP2336 on page 5 for illustration of

how to determine chain arrangement; A. Chain Link (View From Motor); B. 25-50-100

Ton Hoist; C. First Link; D. Chain Weld; E. End Link; F. 75 Ton Hoist Only; G. Chain

Weld Located on Back Side.

First

Link

End

Link

Chain

Weld

Chain

Weld

located

on back

side

25–50–100

Ton

Hoists

75

Ton

Hoist

Only

Chain Link

(view facing Motor)

A

B

C

E

D

F

G

(Dwg. MHP2336)

n

Load Chain ‘C’ Link

Load chain replacement for all hoist models can be accomplished efficiently and

easily by using existing load chain to install new load chain.

1. Using an abrasive wheel, cut a section from end link of existing chain to form a

‘C’ link. Refer to Dwg. MHP2337 on page 5, A. ‘C’ Link.

2. Connect new chain to old chain by inserting end of new chain into ‘C’ link. Make

certain welds and links on new chain match positioning of welds and links on

chain being replaced. For model-specific information, refer to the appropriate

hoist model diagram.

1.378 in.

(35 mm)

“C” Link

A

(Dwg. MHP2337)

CAUTION

•

Do not distort link in any manner. The link must be able to pass over chain

sheaves without binding.

n

Determining Twisted, Kinked or ‘Capsized’ Load Chain

Ensure chain is not twisted, kinked or ‘capsized’ during installation. Refer to Dwg.

MHP0020 on page 5, A. Appearance of Chain Not Twisted; B. Appearance of Chain

Twisted; and Dwg. MHP0043 on page 6, A. Make certain the bottom block has

NOT been flipped through the chain falls.

Twisted Chain

A

Appearance of

Chain Not Twisted

Appearance of

Chain Twisted

B

(Dwg. MHP0020)

Capsized Chain

Form MHD56243 Edition 4

5

Содержание HA3-075

Страница 12: ...R www ingersollrandproducts com...