16605883_ed2

3

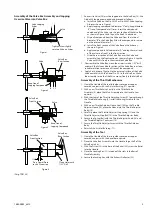

Assembly of the Valve Box Assembly and Lapping

Oversize Valve into Valve Box

Valve Lapping

Arbor

Tighten Screw slightly

to retain Valve on Arbor

Valve

Valve

Valve

Valve Box

Rear Section

Valve Box

Rear Section

Valve Box

Front Section

Valve Box

Front Section

Press Dowel Pin in

to this Dimension

Clean Holes with

1/32” Drill

Keep free of

Lapping Compound

Keep free of

Lapping Compound

Figure 1

Figure 2

Figure 3

Figure 4

1/8”

A

B

B

C

C C

(Dwg. TPB130)

An oversize Valve (20) must be lapped into the Valve Box (18). Use

Grade 320 lapping compound and proceed as follows:

Install the Valve on the No. 29189 or No. 29407 Valve Lapping

Arbor as shown in Figure 1.

Apply lapping compound to diameter “C” only; keep diameter

“B” free of compound at all times. Insert the compound-

coated end of the Valve into the rear section of the Valve Box

as shown in Figure 2 and lap until a free fit is obtained.

Wipe all compound from the Valve and from the internal

diameter “B” in the Valve Box. Allow the compound to remain

on the internal diameter “C”.

Install the front section of the Valve Box on the Arbor as

shown in Figure 3.

Apply compound to Valve diameter “A” and lap the small end

of the valve to a free fit in the front section.

Slide the rear section of the Valve Box over the Valve and

assemble it on the front section as shown in Figure 4. Lap the

Valve until it fits freely in the assembled Valve Box.

2. Disassemble the Valve Box, clean the air ports with a 1/32” drill

and wash the Valve and both sections of the Valve Box in a clean,

suitable solution to remove all trace of the compound.

3. Apply 6 or 8 drops of light oil to the external surface of the Valve

and assemble it with the Dowel Pin (19) in the Valve Box. Shake

the assembly to see that the Valve moves freely in the Valve Box.

Assembly of the Throttle Mechanism

Clamp the Handle of the tool in leather-covered or copper-

covered vise jaws with the Air Inlet Bushing (17) upward.

With a new Throttle Valve Seal (6) on the Throttle Valve

Assembly (5), place the Valve Assembly into the Handle, Seal

upward.

With the stem of the Throttle Adjusting Screw (11) going through

the Throttle Valve Spring (9), install the Spring/Screw into the

Handle.

With a new Throttle Adjuster Sleeve Seal (15A) on the Throttle

Adjuster Sleeve (15), place the Sleeve into the Throttle Adjuster

Body (10).

Carefully place the Throttle Adjuster Stop Spring (12) and the

Throttle Adjuster Stop Ball (13) in the Throttle Adjuster Body.

Secure the Spring/Ball with the Throttle Adjuster Knob (14) and

the Throttle Adjuster Cap Screw (16).

Secure the Throttle Adjuster Screw with the Throttle Adjuster

Body.

Reinstall the Air Inlet Bushing (17).

Assembly of the Tool

Clamp the Handle of the tool in leather-covered or copper-

covered vise jaws with the barrel bore upward.

Place the Valve Box Assembly into the Handle, larger half of the

Valve Box in first.

With the Piston (23) in the bore of the Barrel (24), screw the Barrel

into the Handle.

Place the Locking Key (21) into one of the slots in the Barrel/

Handle Assembly.

Secure the Locking Key with the Exhaust Deflector (22).

1.

a.

b.

c.

d.

e.

f.

1.

2.

3.

4.

5.

6.

7.

8.

1.

2.

3.

4.

5.

Содержание 132

Страница 1: ...16605883 Edition 2 May 2014 Save These Instructions Air Percussive Hammer 132 Maintenance Information ...

Страница 5: ...Notes ...

Страница 6: ...Notes ...

Страница 7: ...Notes ...

Страница 8: ...ingersollrandproducts com 2014 Ingersoll Rand ...