19

MAINTENANCE SECTION

5. Install the Backcap Front Spring (25) and the Control

Valve Assembly, seal end leading, over the shaft of

the Control Bushing. Install the Control Bushing

Seal in annular groove around the bushing shaft.

6. Fit the Backcap Rear Spring (24) against the Control

Valve and thread the entire assembly, spring end lead-

ing, into the Backcap (23). Using a spanner wrench,

tighten the Control Bushing in the Backcap.

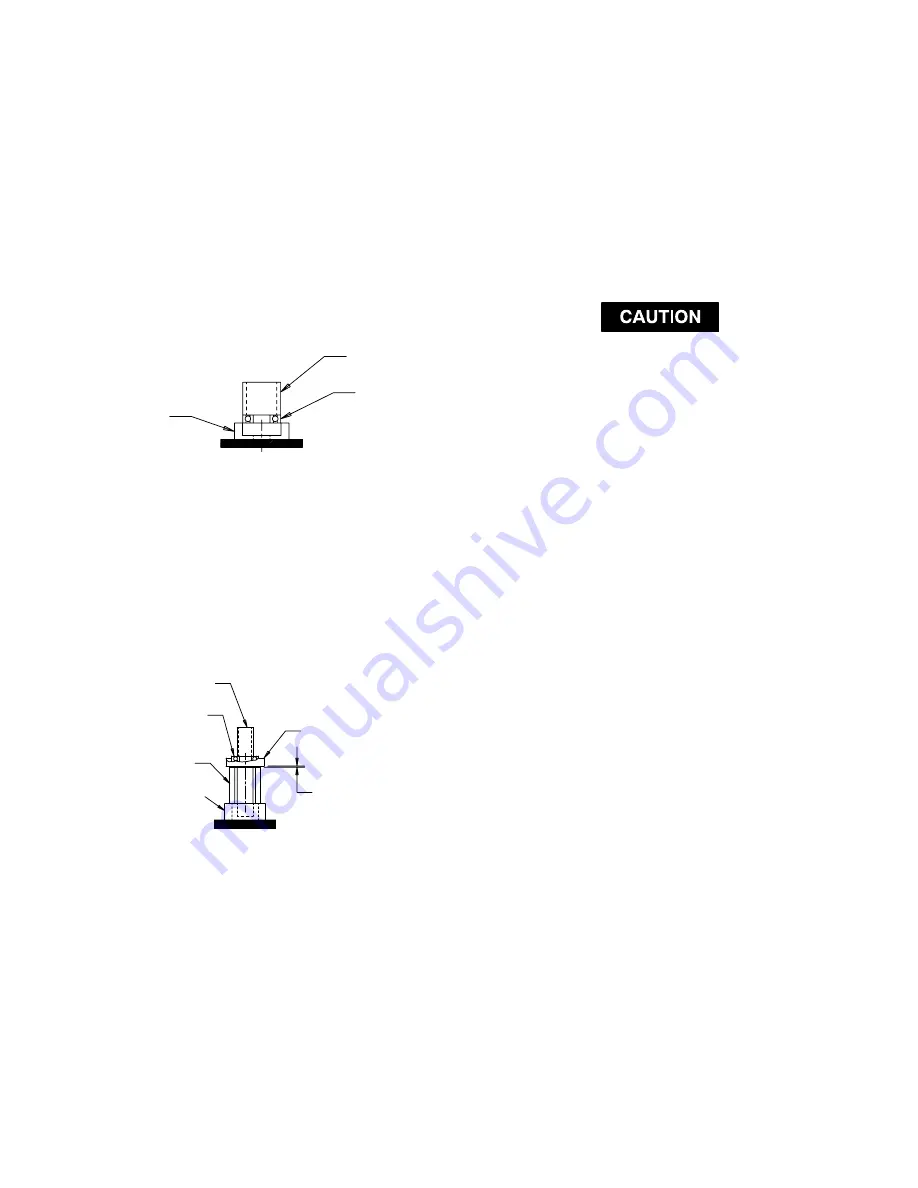

7. Using an arbor press and a piece of tubing that con-

tacts the outer ring of the bearings, press the Front

Rotor Bearing (46) into the Front End Plate (45) and

the Rear Rotor Bearing (39) into the Rear

End Plate (38). (Refer to Dwg. TPD1274.)

END PLATE

TUBING

BEARING

(Dwg. TPD1274)

8. Stand the Rotor (43) on the table of an arbor press.

It should be upright on a flat metal plate having a

clearance hole for the shaft. The shaft with the hex

must be upward.

9. Place a 0.001” (0.025 mm) shim on the upward

surface of the large portion of the rotor body. Using a

piece of tubing that contacts the inner ring of the

bearing, press the Front Rotor Bearing and Front End

Plate, End Plate leading, onto the shaft of the Rotor

until the End Plate contacts the shim. Remove the

shim. (Refer to Dwg. TPD1275.)

PRESSING PLUG

FRONT ROTOR

BEARING

ROTOR

PLATE WITH ROTOR

SHAFT CLEARANCE

FRONT END PLATE

0.001” (0.025 mm)

SHIM SPACE

(Dwg. TPD1275

)

10. Coat each Vane (44) with a thin film of oil and insert

a Vane into each of the rotor vane slots with the

straight edge of the Vane outward.

11. For Model 1100PS4, install the Cylinder (41) over

the Vanes and Rotor making certain the End Plate

Alignment Dowel (46) enters the notch in the end

face of the Cylinder.

For Model 1900PS4, install the Cylinder Assembly

(41) over the Vanes and Rotor making certain the

Cylinder Alignment Pin (42) enters the hole in the

face of the Front End Plate.

12. Stand the assembly on an arbor press table so that the

rotor shaft on the front end plate end contacts the

table. Press the Rear End Plate Assembly, bearing

end trailing, onto the rotor shaft against the Cylinder.

For Model 1100PS4, make certain the End Plate

Alignment Dowel (40) enters the notch in the end

face of the Cylinder.

For Model 1900PS4, make certain the Cylinder

Alignment Pin (42) enters the notch in the end face of

the Cylinder.

13. Stand the assembly on a table with the Front End

Plate Assembly upward.

In the following step, take all precautions

necessary to prevent being burned by handling

warm or hot parts.

14. Using an induction coil or oven, heat the Motor

Housing (1) until the motor opening is large enough

to be placed over the Cylinder. At that time, install

the Housing over the Cylinder and Front End Plate

making sure the radial End Plate Alignment Pin in the

Rear End Plate enters the notch in the Motor

Housing.

15. Allow the assembly to cool and install the Backcap

Gasket (35) and the assembled Backcap (23).

16. Secure the Backcap to the Housing by installing the

three Backcap Mounting Screws (36) and Lock

Washers (37). Tighten each Screw between 45 and

50 in–lb (5.1 and 5.6 Nm) torque.

17. Install the Exhaust Deflector (22) in the bottom of the

handle of the Motor Housing and tighten it between

20 and 25 ft–lb (27 and 34 Nm) torque.

18. Thread the Inlet Bushing (2) into the bottom of the

handle of the Motor Housing (1) and tighten it be-

tween 30 and 35 ft–lb (40 and 47 Nm) torque.

19. Install the Throttle Rod Seal (9) in the groove on the

large hub of the Throttle Rod (8).

20. Install the Throttle Valve Seal (7) in the groove on the

large hub of the Throttle Valve (6).

21. Slide the Throttle Valve, Valve Seal end first, onto the

Throttle Valve Rod.

22. Secure the Throttle Valve Assembly by installing the

Valve Retaining Ring (10) in the small groove on the

Throttle Valve Rod.

23. Install the three Throttle Bushing Seals (5) in the

grooves on the Throttle Bushing (4).

24. Slide the Throttle Bushing Assembly onto the shaft of

the Throttle Valve Rod and position the Trigger (11)

on the same shaft. Install the Trigger Pin (12).

Содержание 1100PS4 Series

Страница 13: ...MAINTENANCE SECTION 13 Dwg TPA1480 ...

Страница 22: ...22 NOTES ...

Страница 23: ...23 NOTES ...