6

Maintenance

Docking Station for Maintenance

Manual Processes for Maintenance

Cleaning the Instrument Exterior

Docking Station for Maintenance

Use the DSX® docking station equipped with a Tango® cradle to dock the Tango TX2 and complete

instrument maintenance.

•

iNet® scheduled maintenance due will be automatically completed upon docking.

•

On-demand instrument maintenance can be completed using the

dock’s

UI buttons.

Manual Processes for Maintenance

Use the information provided below to manually perform bump testing, zeroing, and calibration.

•

Work in an area known to be nonhazardous.

•

Use certified Industrial Scientific calibration gas.

•

Choose gas cylinders that are suitable for the installed sensors and their calibration gas settings.

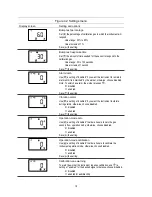

The instrument may be set for the “quick” or “standard”

process-type for calibration and bump testing.

The "quick" process permits only one application of gas.

This setting is suitable when using a “blended” gas

cylinder

—

one cylinder containing both required calibration gases.

The

"standard"

process will prompt its user for the application of each required gas, one at a time. Between

gases, the standard process allows up to five minutes for a change of cylinders. The standard setting is

suitable when more than one gas cylinder is needed to deliver the required calibration gases.

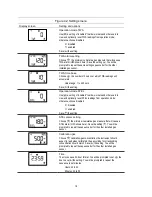

Process At-a-glance

Whether bump testing or calibrating manually, the basic steps are:

•

Gather the needed supplies.

•

Prepare the gas cylinder for use.

•

Access the utility on the instrument.

•

Start the utility.

•

Connect the calibration cup to the instrument.

•

Turn on the gas cylinder.

•

View the results.

Содержание TANGO TX2

Страница 6: ......

Страница 16: ......

Страница 38: ...32 Illustration 7 1 Disassembled Tango TX2 and case top assembly Instrument Case top assembly...