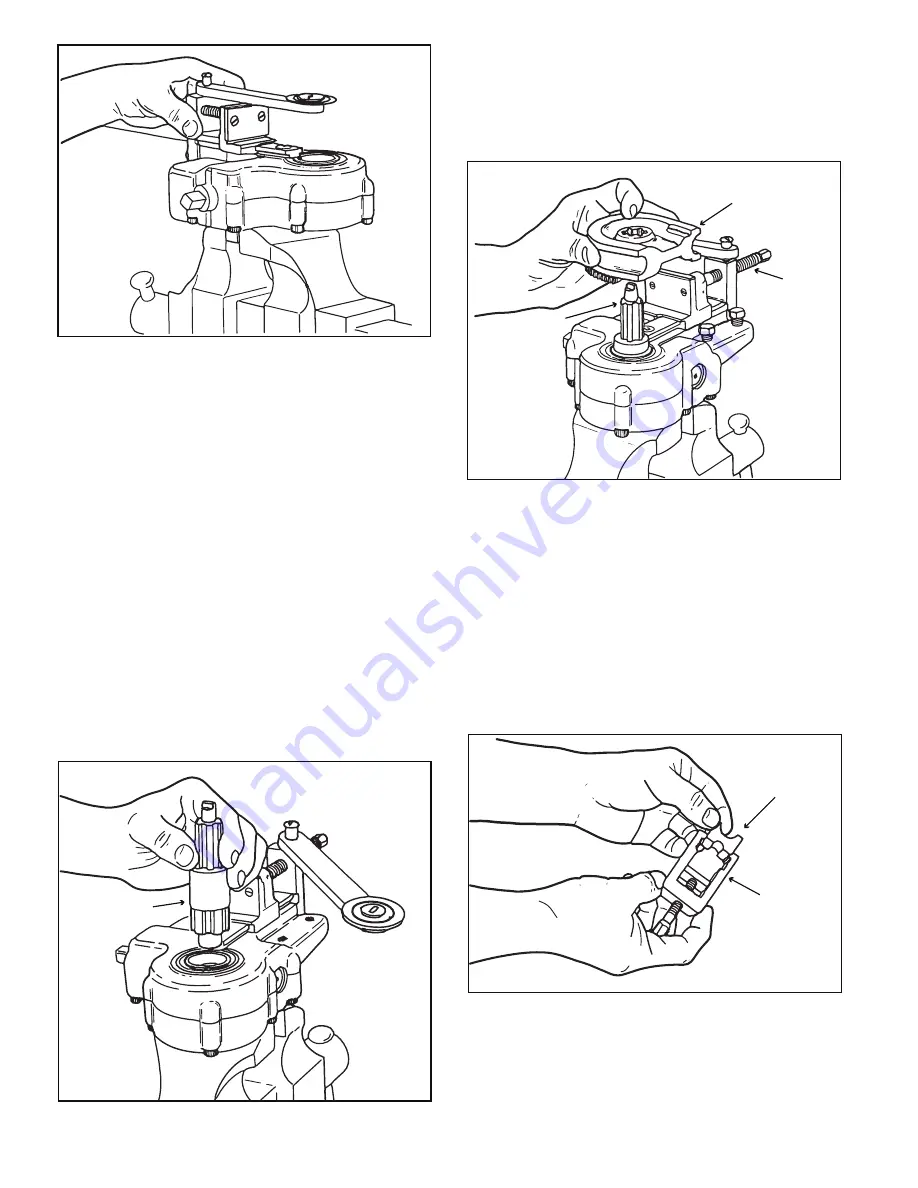

Figure 2. Clamping the Tube Bender Proper in a Vise

11. OPERATION.

12. SETTING UP THE MACHINE. (See Figure 2.)

a. Use a substantial vise with strong, firm-gripping jaws.

Open the jaws wide enough to receive the boss on the

underside of the housing and clamp the tube bender

proper securely between the vise jaws, making certain the

jaws are tight enough to prevent any possibility of the

machine slipping out during actual bending operations.

Considerable force is required on the ratchet handle for

bending 3/4 inch stainless steel tubing, having maximum

wall thickness, and a weak-jawed vise would not hold the

machine.

b. Select the proper size drive shaft to fit the form block

of the required size and insert the drive shaft into the tube

bender proper with the large splines downward. (See

figure 3.) Make certain the drive shaft splines are fully

engaged and that the drive shaft is inserted all the way

into the tube bender so that the lower journal is in the

inner race of the ball bearing.(43, figure 12.)

Figure 3. Installing Drive Shaft in Tube Bender Proper

c. Select the proper size form block and install it on the

drive shaft. (See figure 4.) Rotate the squared countershaft

drive end (37, figure 12) by hand to position the form

block with the starting point of the groove parallel with the

form shoe, when installed.

Figure 4. Placing the Form Block on the

Drive Shaft Spline

NOTE

If the feed screw is turned in too far, the form

shoe slide block will interfere with installation of

the form block.

d. Select the proper size clamp block, turn it so that the

correct groove will be facing outward and slide the clamp

block into the clamp yoke. (See figure 5.)

Figure 5. Installing Clamp Block in Clamp Yoke

e. Place the tube to be bent in the groove of the form

block, at the location of the desired bend, and clamp it

into place with the clamp yoke. (See figure 6.) Make sure

the clamp yoke is in proper position

DRIVE SHAFT

FORM BLOCK

FEED SCREW

DRIVE SHAFT

CLAMP BLOCK

CLAMP YOKE

4