3

10/2018

EN1377027BA

Hazardous fluids

Phases:

assembly, operation, main-

tenance, disposal

Risk:

skin contact, eye contact,

breathing vapors

PPE:

protective gloves, protective eye

glasses, breathing protection

Sharp threads and edges

Phases:

transport, assembly, main-

tenance, disposal

Risk:

risk of cuts

PPE:

protective gloves

3

Avoid damage to property

NOTICE

Deposits and dirt lead to malfunctions

If the control bores are clogged or the

core is blocked by soil the valve no longer

closes or opens.

→

Install a strainer (mesh size ≤ 0,25 mm) in

front of the valve inlet if necessary.

Damages through accumulation of heat

The solenoid will overheat during conti-

nuous duty if the heat can not be radia-

ted. This may shorten the solenoid coil’s

product life cycle.

→

You must not cover the solenoid with paint.

→

You must not encase the solenoid in a

tight housing or in a thermal insulation.

Residual risks

Pressure against valve outlet

Valve only firmly closes in flow

direction.

Fluid freezing

The valve is not designed to with-

stand the fluid freezing.

4

Identifying the valve

The rating plate is situated on the solenoid

body.

use -plug only

9VA/9VA

0,3–10,5

XXXX

230

8407382.9104.23049

40-60

Part no./Bestell-Nr.

V

Hz

PA

bar

D-32545 Bad Oeynhausen

www.imi-precision.com

Buschjost GmbH

Made in Germany

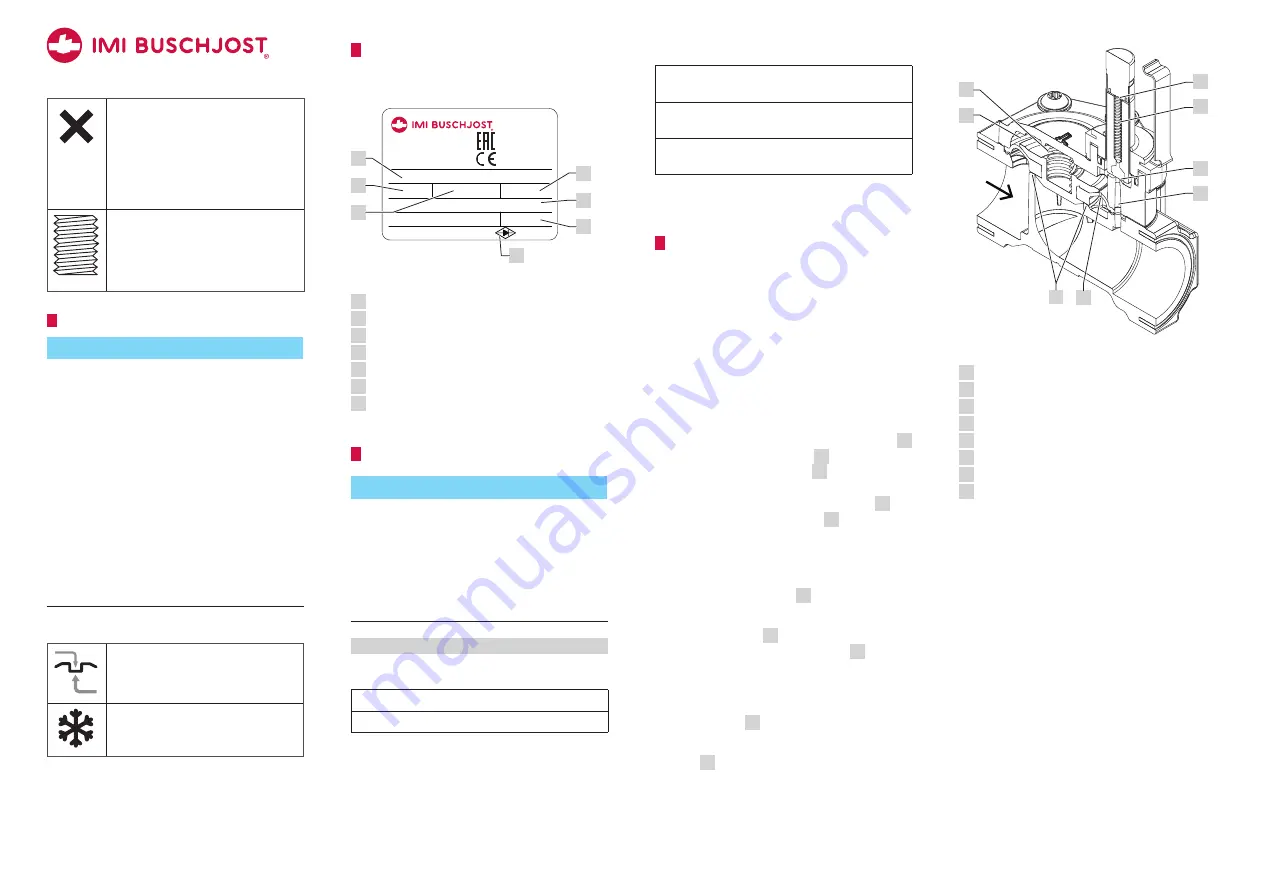

6

2

3

7

1

5

4

Rating plate (example)

1

Order number

2

Operating voltage

3

Frequency of voltage

4

Power consumption inrush/hold

5

Operating pressure range

6

Date of manufacture (week/year)

7

if this marking is shown on the rating plate:

use device socket with rectifier

5

Transport and storage

NOTICE

Damage of the valve

Valve may be damaged if foreign particles

get into the valve.

→

Only transport and store valve in its deli-

very packaging.

→

Take valve out of the packaging immedia-

tely prior to assembly.

prolonged storage at −10°C to +20°C

Avoid during transport:

mechanical loads:

falling off, tipping over

damages to the electrical terminal elements

Avoid during storage:

thermal stress:

permanently increased storage

temperatures; distance to heating devices < 1m

chemical load:

at the storing site through sol-

vents, chemicals, acids, fuels and similar

Weather conditions:

at construction sites strong,

watertight containers are necessary

Unfavourable storing conditions may reduce

the service life of the sealing materials

6

Function

Design

Through-way valve as seat valve with dia-

phragm as sealing device.

Operation

The valve is electromagnetic indirectly-control-

led. The switching function needs a pressure

difference between valve inlet

P

and valve

outlet

A

.

Normal position: closed

Due to the effect of the compression spring

7

inside the core the pilot seat

6

is closed. A

compression spring presses

4

the diaphragm

sealingly to the main valve seat. The opera-

ting fluid flows through the control bore

2

in

the diaphragm to the chamber

3

above the

diaphragm and increases the closing force.

Switching position: open

The magnetic force lifts the core towards the

magnet face of core tube

8

when the sole-

noid is energized.

Since the pilot seat

6

is open the fluid

pressure is reducing from chamber

3

towards

valve outlet.

More fluid is flowing off via the pilot seat to

the chamber than the amount flowing in via

the control bore

4

in the diaphragm.

The differential pressure lifts up the dia-

phragm

1

and opens the main valve seat.

P

A

4

8

1

3

6

5

7

2

Sectional view without solenoid

1

Main valve seat

2

Control bore of diaphragm (pressure build-up)

3

Control space

4

Compression spring above diaphragm

5

Control bore in valve (pressure reduction)

6

Pilot seat

7

Compression spring inside core

8

Magnet face of core tube

A2